I have an Intelliflow 4X160 pump. This pump is designed to help you save money on energy by a variable speed RPM setting. It appears the best way is to observe the GPM with a flow meter. So, I want to add a flow meter and need recommendations for the brand and placement.

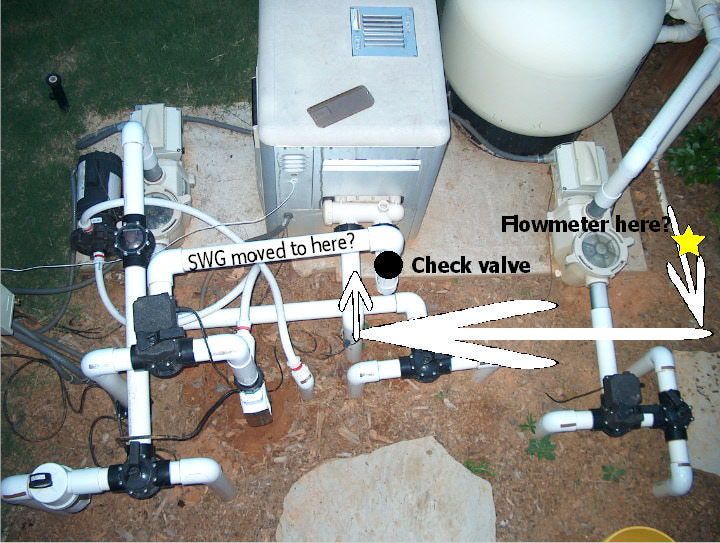

The things I have read say for 2" pipe I really need 20" of straight pipe before the flow meter and 8" after as recommended by Blue/White. I am attaching my set up and hopefully you can see what I am doing.

The best place seems to be where my SWG is today after the actuator valve which would only give me flow in the “pool†mode. That is a vertical pipe. The horizontal pipe right before the actuator is only 20 ½†long (between the 2†elbows). I have 15 ½†between in suction side actuator and the pump basket. I have a horizontal pipe from the pump to the Pentair Multiport that is 19 ½â€.

What do you think about the brand/model and placement? I don't want a really expensive one.

Do some need less space?

Also can they go right after a SWG? It is straight pipe but would that affect the flow meter?

The things I have read say for 2" pipe I really need 20" of straight pipe before the flow meter and 8" after as recommended by Blue/White. I am attaching my set up and hopefully you can see what I am doing.

The best place seems to be where my SWG is today after the actuator valve which would only give me flow in the “pool†mode. That is a vertical pipe. The horizontal pipe right before the actuator is only 20 ½†long (between the 2†elbows). I have 15 ½†between in suction side actuator and the pump basket. I have a horizontal pipe from the pump to the Pentair Multiport that is 19 ½â€.

What do you think about the brand/model and placement? I don't want a really expensive one.

Do some need less space?

Also can they go right after a SWG? It is straight pipe but would that affect the flow meter?