I have a pretty large L Shaped pool that I built about 7 years ago, and now I am going to re-do the equipment pad, so I'm looking to improve the plumbing setup. The largest issue is that I have 3 suction lines (all coming from Aqua Genies, all 1.5" Pipe) and then those are joined at the pad prior to running into the pump.

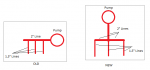

Where I'm looking to improve this is that currently I have them run in series, which does not give me equal suction across the various skimmers or equal pressure on the returns, so I'm looking to fix that. Here's an artist's representation (attached)... (ok, not an artist and it's MS Paint, not Visio... so be nice) of what I'm thinking on the suction side, return side would be similar.

[attachment=0:2dytr4tb]plumbing.png[/attachment:2dytr4tb]

I can re-do any pad plumbing but all lines are under a patio, so sadly I can't redo everything 2".

Does this look better than what I have now? Should I be looking at 2.5" to the pump or is 2" good enough where 3x1.5" lines join?

Any feedback on this would be really appreciated, and any other ideas on improving it would be great.

Where I'm looking to improve this is that currently I have them run in series, which does not give me equal suction across the various skimmers or equal pressure on the returns, so I'm looking to fix that. Here's an artist's representation (attached)... (ok, not an artist and it's MS Paint, not Visio... so be nice) of what I'm thinking on the suction side, return side would be similar.

[attachment=0:2dytr4tb]plumbing.png[/attachment:2dytr4tb]

I can re-do any pad plumbing but all lines are under a patio, so sadly I can't redo everything 2".

Does this look better than what I have now? Should I be looking at 2.5" to the pump or is 2" good enough where 3x1.5" lines join?

Any feedback on this would be really appreciated, and any other ideas on improving it would be great.

Welcome to TFP!!!

Welcome to TFP!!!