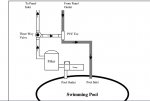

Well, it's finally done but I'm having an issue I can't seem to find an answer to. Pool fill was Sunday, 5/26, and plumbing was completed Monday, 5/27. With 20' of 1.5" PVC and 30+ glue joints, I had only one leak at a threaded teflon junction right at the pump outlet. This was fixed today along with install of a union fitting. My issue is that the solar panel return seems poor compared to the supply. There is no recognizable PSI difference when panel is engaged - the guage (brand new pump/filter) does react when I momentarily cut off the supply altogether. I thought that repairing the leak would boost the solar return but it didn't. The return does react slightly when the panel is disengaged/re-engaged and it did take some time when initially turned on for water to appear in the return (I used clear tubing). The panel supply tubing swells impressively, but no such luck for the return.

I plumbed the supply on the bottom, return on the top - was this incorrect? Should it be reversed?

The panel runs ever so slightly 'downhill' from the pool - perhaps 3" for every 12'. (the pad needed leveling) Do I need to raise the end of the pool rack to assist the pump?

The pressure going into the pool itself is impressive, especially compared to the previous 530gph wimpy pump.

Is there a baffle in-between the two sections of panel, in either or both ends of the panel? Should it be removed? Don't wanna blow up the panels!

Please help. Pics attached. In pic PanelReturn you can see the tube about 1/2 way filled, quite unliike the supply.

We've had a lot of rain the last few days and I was advised to start Dichlor ASAP. With leak fixed I did, after verifying PH of 7.8 and Chlorine of 0.5. Water looks cloudy and a bit green. Temp 58F, measured at the supply outlet. Added 3.5oz. of Dichlor, pump running.

I plumbed the supply on the bottom, return on the top - was this incorrect? Should it be reversed?

The panel runs ever so slightly 'downhill' from the pool - perhaps 3" for every 12'. (the pad needed leveling) Do I need to raise the end of the pool rack to assist the pump?

The pressure going into the pool itself is impressive, especially compared to the previous 530gph wimpy pump.

Is there a baffle in-between the two sections of panel, in either or both ends of the panel? Should it be removed? Don't wanna blow up the panels!

Please help. Pics attached. In pic PanelReturn you can see the tube about 1/2 way filled, quite unliike the supply.

We've had a lot of rain the last few days and I was advised to start Dichlor ASAP. With leak fixed I did, after verifying PH of 7.8 and Chlorine of 0.5. Water looks cloudy and a bit green. Temp 58F, measured at the supply outlet. Added 3.5oz. of Dichlor, pump running.