Hi

I am trying to work out if it is worth upgrading the old 32mm (1 1/4") plumbing that I have on my 35yo (give or take I'm guessing) pool. I currently have a suction leak somewhere around the skimmer that I can hear when I vacuum the pool, (or I put my hand over the suction port,) but expect it to get worse over time. I don't see air coming out the return, but the lint basket on the pump does have air in it, and there are large amounts of air after backwashing. I am also getting some sand in the pool after vacuuming, but that is a question for another thread. I don’t think that would take too much to fix the leak, but I am thinking am I going to be throwing good money at a now bad solution?

Here is my current setup to the best of my knowledge I only took over the place a few months ago so don’t know the history, and am new to all this pool stuff. All pipe work initially 32mm until it gets to the Pad, where it goes to 40mm. It is a simple solution with a single outlet at skimmer that goes to a single return via the pump & filter. (No heater/chlorinators etc, yet.)

What I am thinking of.

Pump is a Hurlcon E170 Single Speed Pump.

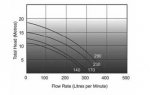

Pump is rated at 170L/m @ 8m Head (See links in Sig for Web Pages and PDF info).

I measured the pump power draw at 770watts (with a Watt Meter,) but is rated at 850w.

Pump is a 0.75hp.

Unknown Vacuum as Pump does not have any drains drilled & Plugged, but I do have a gauge.

Clean filter pressure is 9PSI.

Filter is a Astral FT55.

Unknown multiport valve on Filter

The filter is rated at 160L/m.

Using the pressure and the assumptions on the Hydraulics 101 thread, I suspect that I am getting approx 11m of head, which using the pump curve (located on the brochure) gives me approx 100L/m.

So the question I really have is should I upgrade the existing plumbing and if I do, should I go for 40 or 50mm? Doing the job should not be too hard as it is all tiled in the area. And if I do this, am I going to increase my flow to a point that I have too much for my filter to handle? I have to make sure that this upgrade makes $$$ sense as once I convince myself I have to turn around and convince the financial controller (Wife).

I'm currently pricing up the costs of the parts if I make the upgrade, but need some calculations to confirm that it is going to be worth doing.

Attached is photo of Pad for reference.

As it is coming into spring here, am thinking that I should do something before our season kicks into gear.

I am trying to work out if it is worth upgrading the old 32mm (1 1/4") plumbing that I have on my 35yo (give or take I'm guessing) pool. I currently have a suction leak somewhere around the skimmer that I can hear when I vacuum the pool, (or I put my hand over the suction port,) but expect it to get worse over time. I don't see air coming out the return, but the lint basket on the pump does have air in it, and there are large amounts of air after backwashing. I am also getting some sand in the pool after vacuuming, but that is a question for another thread. I don’t think that would take too much to fix the leak, but I am thinking am I going to be throwing good money at a now bad solution?

Here is my current setup to the best of my knowledge I only took over the place a few months ago so don’t know the history, and am new to all this pool stuff. All pipe work initially 32mm until it gets to the Pad, where it goes to 40mm. It is a simple solution with a single outlet at skimmer that goes to a single return via the pump & filter. (No heater/chlorinators etc, yet.)

Skimmer with unused main drain inlet and used suction outlet. No main drain in the pool.

Elbow at 0.2m down (approx 0.7m underground)

4.9m Straight

Elbow

1.5 Straight

Elbow

0.9m Up

Elbow

0.2 Into Garage

Threaded joiner to

Elbow

0.3m straight adapted to 40mm pipe using several adaptors & Joiners

Elbow

Butt join to Pump inlet

0.19 straight out of pump

45 Elbow

0.12 Straight

Elbow

0.07 Straight into Filter

0.2 Straight out of Filter

Elbow

0.34m Straight

Elbow

0.18 Straight

Elbow

0.49 Straight

Elbow

Adapted to 32mm Thread join

0.3 Straight out of Garage including adaptor above

Elbow

0.7 Straight down into ground

Elbow

1.5m Straight

Elbow

2.4m Straight

Elbow

0.2m Straight into pool return

No eye in return

What I am thinking of.

Joining the 2 outlets of the skimmer to the same return using

2x 32-40(or 50)mm adaptor, 3x Elbows, 1x T, Couple of short straights

4.5m Straight

Elbow

1.4 Straight

Elbow

1.0 Straight

Elbow

0.3 Straight into Garage then straight into Pump inlet

0.19 straight out of pump

45 Elbow

0.12 Straight

Elbow

0.2 Straight into Filter

0.07 Straight out of Filter

Elbow

Joiner/50mm Adaptor

0.6 Straight out of Garage (Including Straight and joiner)

Elbow

1.0 Straight

Elbow

1.5 Straight

Elbow

2.4 Straight

Elbow

0.2 Straight adapted to existing 32mm Return

Maybe fit eye in return

Pump is a Hurlcon E170 Single Speed Pump.

Pump is rated at 170L/m @ 8m Head (See links in Sig for Web Pages and PDF info).

I measured the pump power draw at 770watts (with a Watt Meter,) but is rated at 850w.

Pump is a 0.75hp.

Unknown Vacuum as Pump does not have any drains drilled & Plugged, but I do have a gauge.

Clean filter pressure is 9PSI.

Filter is a Astral FT55.

Unknown multiport valve on Filter

The filter is rated at 160L/m.

Using the pressure and the assumptions on the Hydraulics 101 thread, I suspect that I am getting approx 11m of head, which using the pump curve (located on the brochure) gives me approx 100L/m.

So the question I really have is should I upgrade the existing plumbing and if I do, should I go for 40 or 50mm? Doing the job should not be too hard as it is all tiled in the area. And if I do this, am I going to increase my flow to a point that I have too much for my filter to handle? I have to make sure that this upgrade makes $$$ sense as once I convince myself I have to turn around and convince the financial controller (Wife).

I'm currently pricing up the costs of the parts if I make the upgrade, but need some calculations to confirm that it is going to be worth doing.

Attached is photo of Pad for reference.

As it is coming into spring here, am thinking that I should do something before our season kicks into gear.