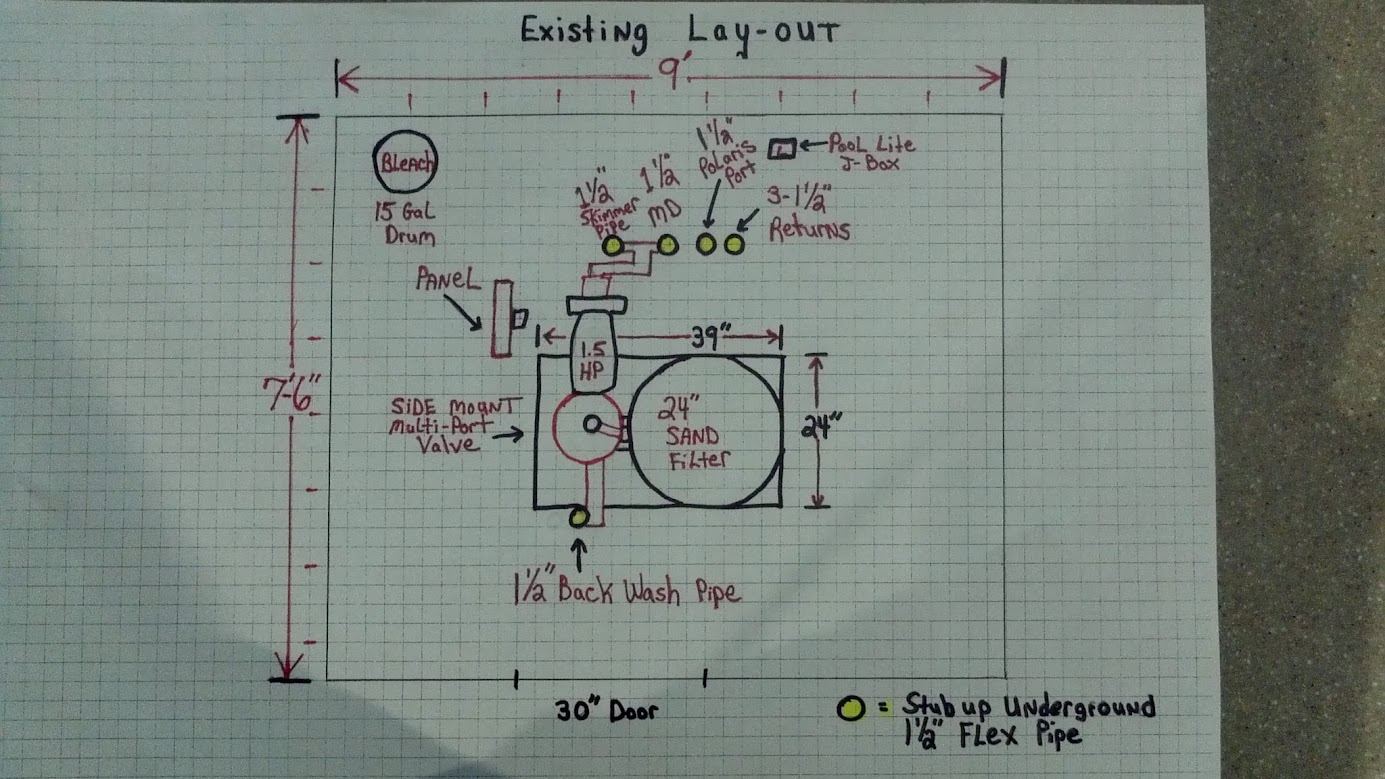

I will be redoing my pad at the end of this season and figured I would start this thread now because I know I'll have a bunch of questions and ideas as it gets closer to the renovation, I'll be sure to post some before/during/after pics as well

For now the one thing that has been on my mind is..

Suction to discharge tie line for vac ?? I currently have a dedicated pressure side line for my Polaris 360 cleaner and was curious if its logical to have the filter outlet piped to it as it is right now but also adding a suction side to it as well, with proper isolation valves on both lines so this way if I decided to try or go with a suction side auto vac setup in the future it can easily be configured just by a quick valve alignment and not have to redo any piping once again...or if I decide I dont like the way the suction type vac works after all I can easily switch back to the pressure type? It may sound crazy but I figured if its just a matter of an extra valve or two and a bit more PVC to have that convenient option what the heck ??

For now the one thing that has been on my mind is..

Suction to discharge tie line for vac ?? I currently have a dedicated pressure side line for my Polaris 360 cleaner and was curious if its logical to have the filter outlet piped to it as it is right now but also adding a suction side to it as well, with proper isolation valves on both lines so this way if I decided to try or go with a suction side auto vac setup in the future it can easily be configured just by a quick valve alignment and not have to redo any piping once again...or if I decide I dont like the way the suction type vac works after all I can easily switch back to the pressure type? It may sound crazy but I figured if its just a matter of an extra valve or two and a bit more PVC to have that convenient option what the heck ??