- Apr 23, 2008

- 342

Hey everyone,

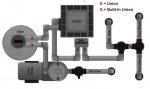

I just bought a new top mount filter and I'm getting a heater for the first time so I thought it's time to just replumb everything by my equipment pad since it needs it anyway. I attached a picture of the design I came up with.

I have 2 points of concern with it:

1) Too many unions. Unions are great, but they can also be points of small air leaks.

2) Exiting the heater I have 2 Jandy valves rather than just 1, so that I can plumb in my water slide. I feel like there must be a better way to plumb in a slide. Thoughts?

Thanks!

I just bought a new top mount filter and I'm getting a heater for the first time so I thought it's time to just replumb everything by my equipment pad since it needs it anyway. I attached a picture of the design I came up with.

I have 2 points of concern with it:

1) Too many unions. Unions are great, but they can also be points of small air leaks.

2) Exiting the heater I have 2 Jandy valves rather than just 1, so that I can plumb in my water slide. I feel like there must be a better way to plumb in a slide. Thoughts?

Thanks!