The panels are on racks with the "Out" end of the rack elevated 6 inches. I raised it primarily to help rain water not pool on the panels. Originally the rack design was a flat frame with cross members and a center beam. We had a hard rain and they sagged down into the frame because of the weight of the water on top. I hated to eat the cost but went back and added 1/4 inch plywood to the top of each frame. I water sealed it for some protection. So, some water in the tubes will drain down.

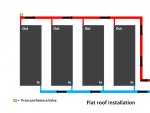

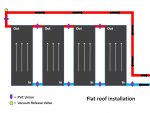

I'm very close to buying all of the unions, elbows, etc to plumb it all up. Sch 40 of course. I wanted to post one more diagram and see if this one is better, worse, or equal to the last one I posted. It is less pipe and fittings but I'm not sure which one is the most efficient for heat and flow.

I put the VRV on the PVC pipe instead of the panel in the diagram. Maybe that doesn't change anything.

Thank you guys for the great advice. The plan is coming together well because of your input.

[attachment=2 d5in355]Marked panels 2.jpg[/attachment

d5in355]Marked panels 2.jpg[/attachment d5in355]

d5in355]

[attachment=1 d5in355]Panels 1.JPG[/attachment

d5in355]Panels 1.JPG[/attachment d5in355]

d5in355]

[attachment=0 d5in355]Panels 4.JPG[/attachment

d5in355]Panels 4.JPG[/attachment d5in355]

d5in355]

I'm very close to buying all of the unions, elbows, etc to plumb it all up. Sch 40 of course. I wanted to post one more diagram and see if this one is better, worse, or equal to the last one I posted. It is less pipe and fittings but I'm not sure which one is the most efficient for heat and flow.

I put the VRV on the PVC pipe instead of the panel in the diagram. Maybe that doesn't change anything.

Thank you guys for the great advice. The plan is coming together well because of your input.

[attachment=2

[attachment=1

[attachment=0