two parts to the question

1) electrical - the pump comes with a regular plug, do I cut the end off and wire it directly into the hayward ecommand 4 breaker box?

If so, do i put it in parallel with whatever my pump is attached to so it goes on when the pool pump goes on?

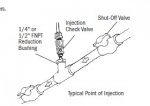

2) plumbing - any tips for tapping into the actual pool plumbing? do i use a drill bit to drill the right sized hole?

how do i seal the whole thing?

1) electrical - the pump comes with a regular plug, do I cut the end off and wire it directly into the hayward ecommand 4 breaker box?

If so, do i put it in parallel with whatever my pump is attached to so it goes on when the pool pump goes on?

2) plumbing - any tips for tapping into the actual pool plumbing? do i use a drill bit to drill the right sized hole?

how do i seal the whole thing?