- Feb 19, 2012

- 78

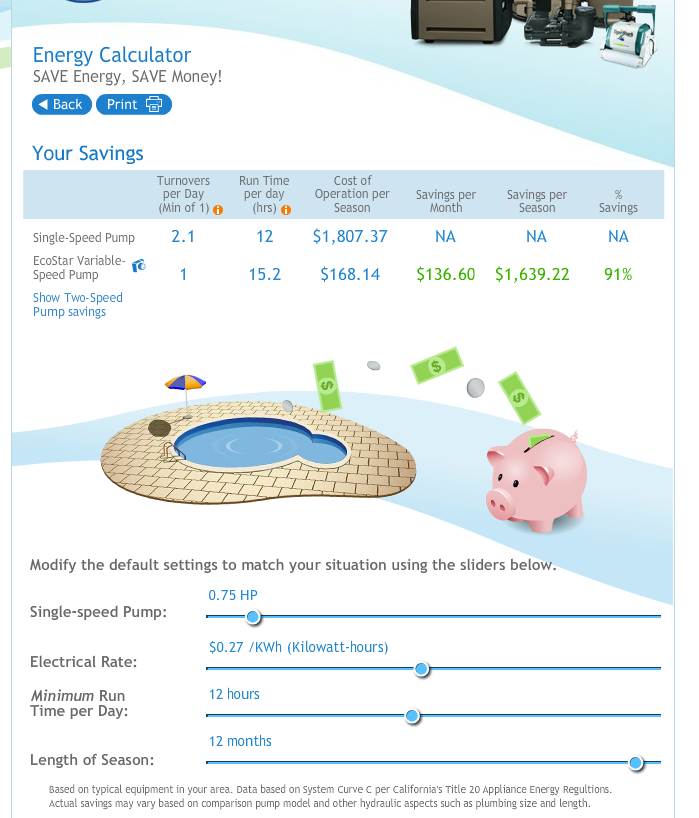

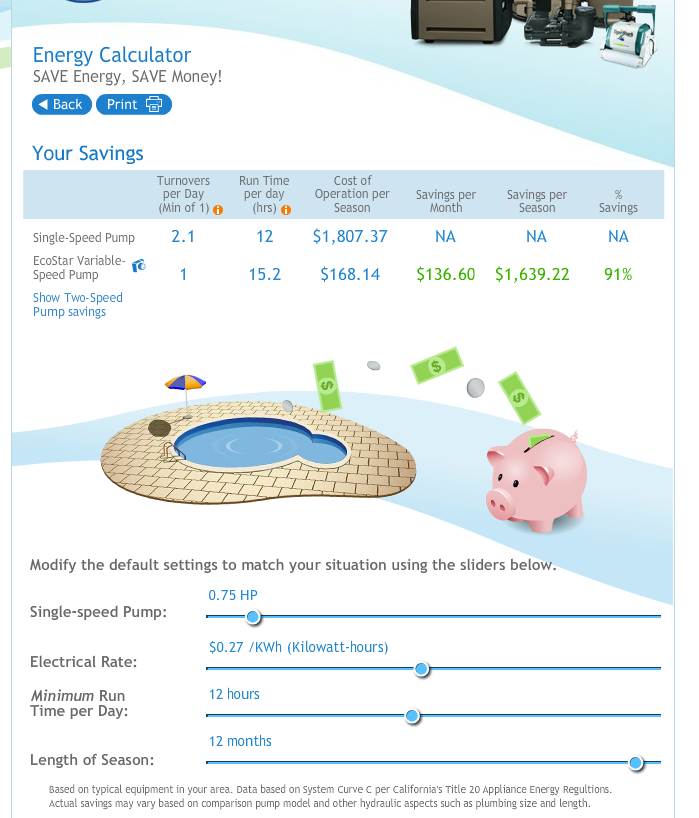

Hi guys. New member here. We're about to get a contractor to build a 25,000 gallon in-ground pool and was looking at using the variable speed pumps by either pentair or hayward. it seems according to their energy calculator that the savings on electricity is quite substantial that in fact one can recoup the purchase cost in a year's time. is this too good to be true?

i was calculating manually the cost of running a 3/4 hp pump and i came up with just $650 while their websites calculates at $1800 and $2100. what gives?! now i'm starting to question their energy savings claim. did i miss something on my calculation?

single speed 3/4 hp = 560W or 0.56kW

0.56kW x 12 hrs = 6.72kWh x 365 days = 2453 kWh/year x $0.27/kWh (rate) = $662

i was calculating manually the cost of running a 3/4 hp pump and i came up with just $650 while their websites calculates at $1800 and $2100. what gives?! now i'm starting to question their energy savings claim. did i miss something on my calculation?

single speed 3/4 hp = 560W or 0.56kW

0.56kW x 12 hrs = 6.72kWh x 365 days = 2453 kWh/year x $0.27/kWh (rate) = $662