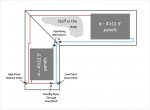

The current setup:

- Built in the 70s

- ~20000 gallons

- Hayward RS1500 pump with AOSmith ST1152 (1.5HP, 1.47SF) pump ... does this seem like a good pairing?

- Hayward DE6020 filter

- Raypac RP2100 gas heater (rarely used)

- Equipment pad 15' from skimmer at the water level

- 1 main drain plumbed to 1 skimmer to pad using 1.5" pipe (while the deck was ripped apart for the skimmer ... I probably should have run the drain directly to the pad huh?)

- Plumbing at pad is half 1.5" and half 2" ... planning to redo it all in 2"

- There are 3 1.5" return lines, but I only currently use 1 at a time.

- main return to 4x 1"(?) eye balls (normal mode)

- return to old whip cleaning system ~8-9 1" holes (never used)

- return to 3x 1" eye balls with air induction at bench seat (rarely used)

- DIY solar system with 60' 1.5" pvc run to single story house to 12 ~100' 3/4" black irrigation-like pipe randomly twisted around the roof. The roof is not as steep as typical roofs, but it is not flat either. Note this is currently plumbed AFTER the heater (??? I plan to change this)

- Normal clean filter pressure ~25psi (no-solar) or ~28psi (with solar)

- Waterfall that is Ts off off right after the filter with a separate ball valve (rarely used as a lot of the water does not make it back to the pool ... another previous DIY project I think)

The questions:

1. Does the current setup (pump/motor/filter/plumbing) make sense?

The pairing of a single 1.5" return with a 2.2HP motor on a RS1500 pump with a large DE filter seems off to me. If the suction plumbing is limited to <60 GPM, how am I supposed to feed a large filter that recommends a higher flow rate than that? Or is the large pump sucking the water through there FAST?

2. Can I modify the solar setup to what I want?

My desire was to replace the small DIY system with 11 4'x12.5' Heliocol panels (got a good deal on them used) ... plumbing of these on the roof may become another topic. I then got concerned that they recommend 5GPM / panel or 55GPM. Can I even get that amount of water to the roof with my current setup? Would increasing the plumbing size to the solar help or is the real limiting factor the single suction line? Would it help to replace about half of the suction line with larger pipe since replacing all of it would be a nightmare at this point?

3. Are plumbing and/or pump modifications required/recommended?

Given my current setup and my solar desires, would any plumbing changes be desirable? Could I benefit from a better pump?

4. Why didn't I think ahead last year when we resurfaced everything and replaced the skimmer?

Had I an forethought, when the skimmer was dug up and replaced due to a leak, I probably should have tried to plumb the main drain directly to the pad since I believe the suction is now my limiting factor.

One thought I just had was that there is a hole under the waterfall that does not appear to be used by anything. I am guessing (based on some cut wires nearby) that there used to be a separate pump on the waterfall. Maybe this sidewall could become another suction line? Although I would have to verify I can get access to the plumbing and I am not sure of the size. Also, I am not sure how I would cover it ... or if it is even safe to use a suction like that.

My long term plan is to add automation control with a SWG and solar control, although in the near term I am focusing on the manual solar option. The automation controller could then allow me to go to a variable speed pump if it made sense. I suppose I could use a low RPM when the solar is not on (like in the winter months) and use a high RPM for when solar is on.

So, hopefully this will get a dialog started. I was trying to figure out my current head and whether the pressures and everything currently make sense and got sidetracked when it appeared that my suctions line size ... basically sucks

- Built in the 70s

- ~20000 gallons

- Hayward RS1500 pump with AOSmith ST1152 (1.5HP, 1.47SF) pump ... does this seem like a good pairing?

- Hayward DE6020 filter

- Raypac RP2100 gas heater (rarely used)

- Equipment pad 15' from skimmer at the water level

- 1 main drain plumbed to 1 skimmer to pad using 1.5" pipe (while the deck was ripped apart for the skimmer ... I probably should have run the drain directly to the pad huh?)

- Plumbing at pad is half 1.5" and half 2" ... planning to redo it all in 2"

- There are 3 1.5" return lines, but I only currently use 1 at a time.

- main return to 4x 1"(?) eye balls (normal mode)

- return to old whip cleaning system ~8-9 1" holes (never used)

- return to 3x 1" eye balls with air induction at bench seat (rarely used)

- DIY solar system with 60' 1.5" pvc run to single story house to 12 ~100' 3/4" black irrigation-like pipe randomly twisted around the roof. The roof is not as steep as typical roofs, but it is not flat either. Note this is currently plumbed AFTER the heater (??? I plan to change this)

- Normal clean filter pressure ~25psi (no-solar) or ~28psi (with solar)

- Waterfall that is Ts off off right after the filter with a separate ball valve (rarely used as a lot of the water does not make it back to the pool ... another previous DIY project I think)

The questions:

1. Does the current setup (pump/motor/filter/plumbing) make sense?

The pairing of a single 1.5" return with a 2.2HP motor on a RS1500 pump with a large DE filter seems off to me. If the suction plumbing is limited to <60 GPM, how am I supposed to feed a large filter that recommends a higher flow rate than that? Or is the large pump sucking the water through there FAST?

2. Can I modify the solar setup to what I want?

My desire was to replace the small DIY system with 11 4'x12.5' Heliocol panels (got a good deal on them used) ... plumbing of these on the roof may become another topic. I then got concerned that they recommend 5GPM / panel or 55GPM. Can I even get that amount of water to the roof with my current setup? Would increasing the plumbing size to the solar help or is the real limiting factor the single suction line? Would it help to replace about half of the suction line with larger pipe since replacing all of it would be a nightmare at this point?

3. Are plumbing and/or pump modifications required/recommended?

Given my current setup and my solar desires, would any plumbing changes be desirable? Could I benefit from a better pump?

4. Why didn't I think ahead last year when we resurfaced everything and replaced the skimmer?

Had I an forethought, when the skimmer was dug up and replaced due to a leak, I probably should have tried to plumb the main drain directly to the pad since I believe the suction is now my limiting factor.

One thought I just had was that there is a hole under the waterfall that does not appear to be used by anything. I am guessing (based on some cut wires nearby) that there used to be a separate pump on the waterfall. Maybe this sidewall could become another suction line? Although I would have to verify I can get access to the plumbing and I am not sure of the size. Also, I am not sure how I would cover it ... or if it is even safe to use a suction like that.

My long term plan is to add automation control with a SWG and solar control, although in the near term I am focusing on the manual solar option. The automation controller could then allow me to go to a variable speed pump if it made sense. I suppose I could use a low RPM when the solar is not on (like in the winter months) and use a high RPM for when solar is on.

So, hopefully this will get a dialog started. I was trying to figure out my current head and whether the pressures and everything currently make sense and got sidetracked when it appeared that my suctions line size ... basically sucks