- Nov 26, 2010

- 11

Hello, I've been reading\learning a lot from this site, the internet is so awesome ! lol

Anyways, I wasn't too sure where to put this thread, but here goes...

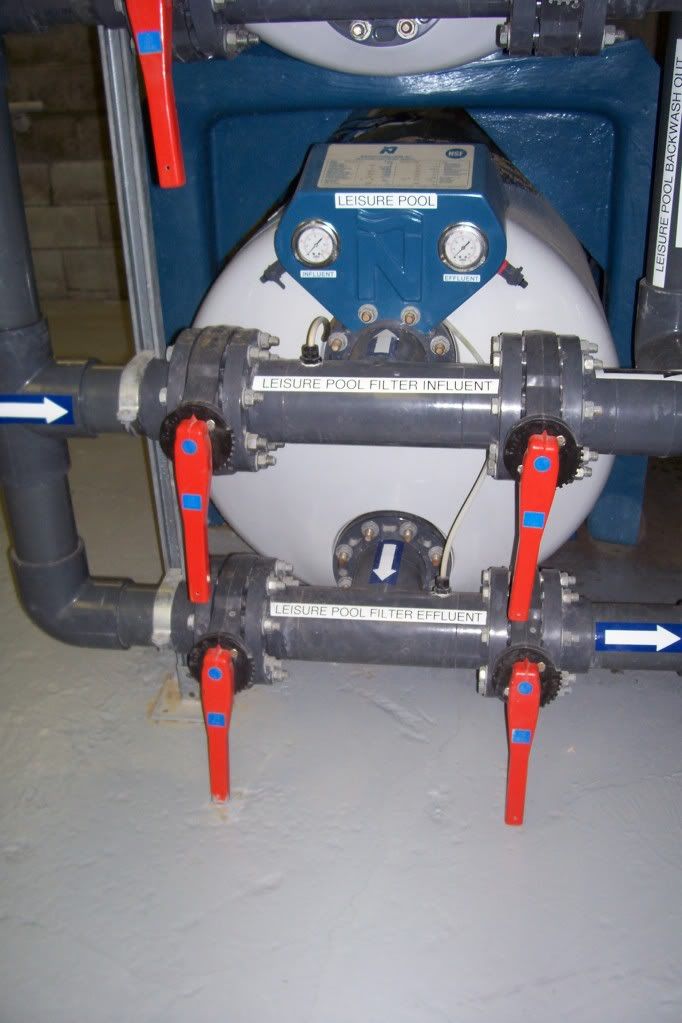

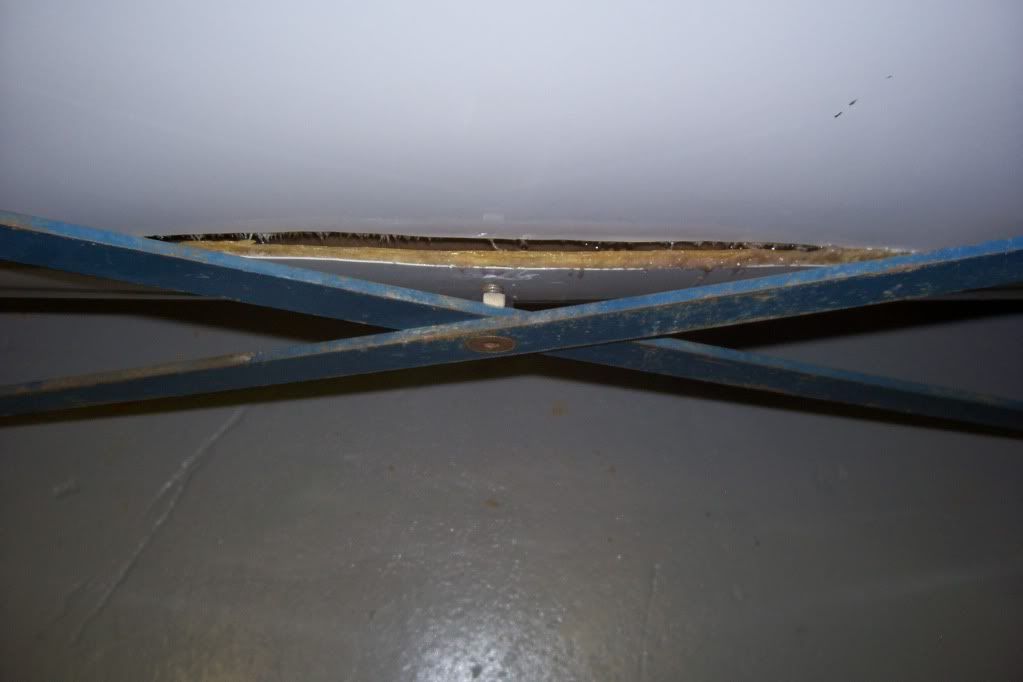

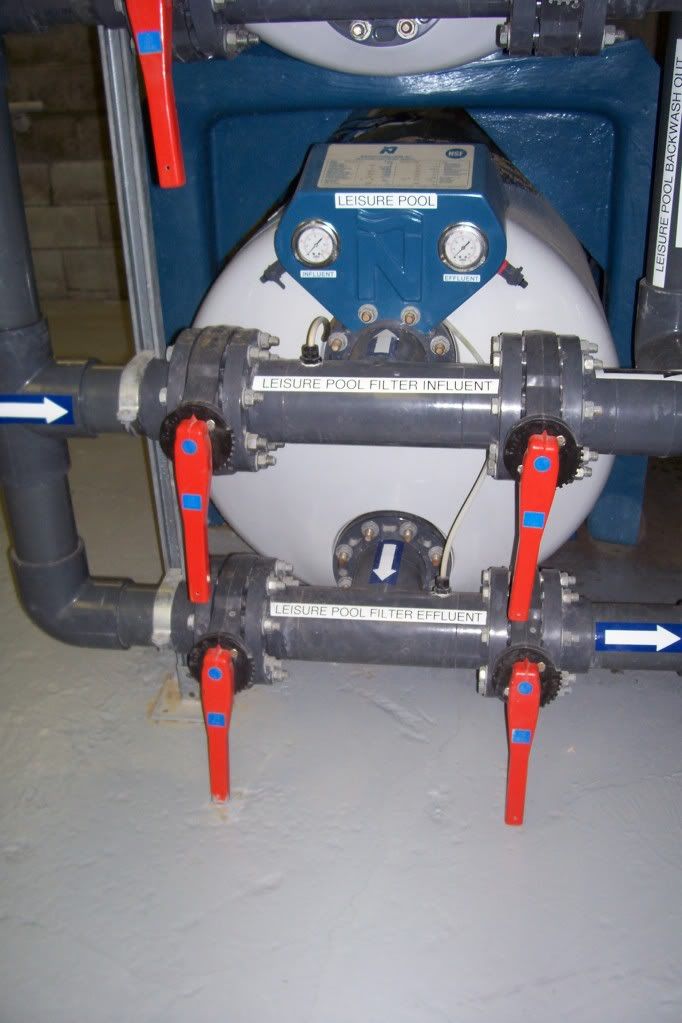

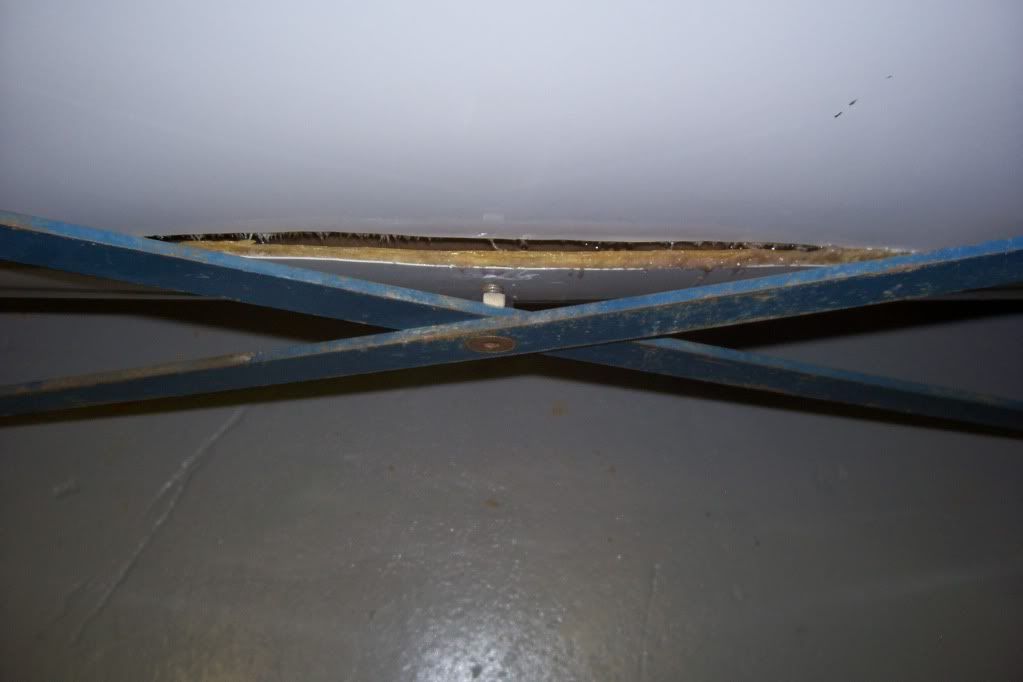

I work at a city run facility, with 2 pools the one in question is a 25m 132,000 gallon fresh water pool. We have 2 horizontal sand filters with usually around 11lbs pressure on the tanks, after night shift staff left the lower tank burst with about a 3ft crack\gash horizontally along the mid section. It is a fiber glass shell about 60in diameter and maybe 8ft long. The pump room was flooded with several inches of water, and the pool water level was done about 1ft. We valved off the affected filter and by the end of that night we were able to get the pool clear and ready to re open.

I know a back wash done and normally completed with no issues 2hrs. before staff left.

I was just curious if this is a fatigue issue or if improper valving during backwash could have caused this ? I can't see that low of a pressure causing this damage, & I would think if it was valved improperly during backwash, it would have burst during the backwash cycle.

Input is appreciated, and thanks in advance, here are some pictures...

Anyways, I wasn't too sure where to put this thread, but here goes...

I work at a city run facility, with 2 pools the one in question is a 25m 132,000 gallon fresh water pool. We have 2 horizontal sand filters with usually around 11lbs pressure on the tanks, after night shift staff left the lower tank burst with about a 3ft crack\gash horizontally along the mid section. It is a fiber glass shell about 60in diameter and maybe 8ft long. The pump room was flooded with several inches of water, and the pool water level was done about 1ft. We valved off the affected filter and by the end of that night we were able to get the pool clear and ready to re open.

I know a back wash done and normally completed with no issues 2hrs. before staff left.

I was just curious if this is a fatigue issue or if improper valving during backwash could have caused this ? I can't see that low of a pressure causing this damage, & I would think if it was valved improperly during backwash, it would have burst during the backwash cycle.

Input is appreciated, and thanks in advance, here are some pictures...