This is from my SoCal pool build thread, but I'm hoping to get a little more info quick since I'm meeting with my plumber tomorrow morning to go over any final changes. Gunite is next week.

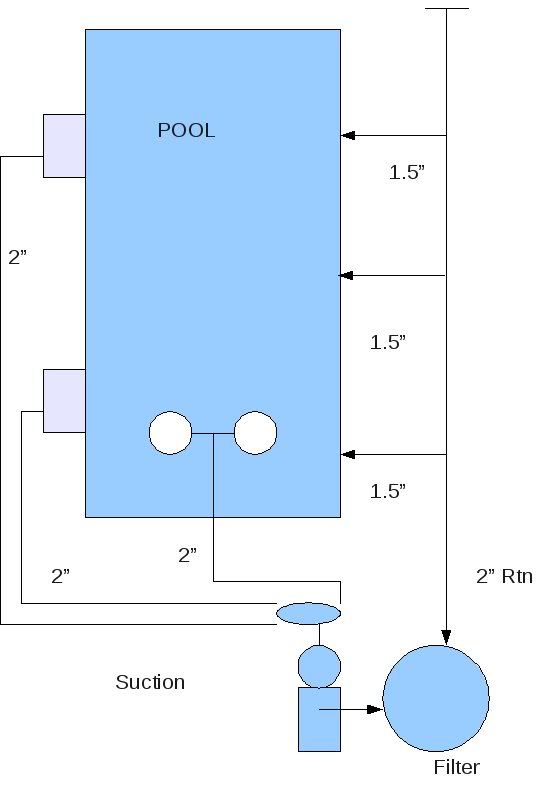

Please see the pic below. The pool as 4 returns and the spa has 2 for a total of 6 returns from the filter. At this moment the 4 pool returns are in a serial run starting with a 2" pipe and ending with a 1" pipe. Each of the 4 pipes that enter the pool are 1". I mentioned to my plumber that I'd like to cut off the last 1" run and connect a 2" pipe all the way back to the original 2" run to create a loop... keeping the 4th return in place through a Tee. He has strong feelings against this because he doesn't think there will be enough pressure to move water in the pool. The suction side is fed by 2 separate 2.5" runs from 2 skimmers. One skimmer is also supporting the main drains.

Will return pressure be a problem if we loop it back? Also, are 1" outlets big enough? It just "feels" undersized, but I don't have science or experience to lean on here.

Thanks all.

[attachment=0:1o9cp720]pool return.jpg[/attachment:1o9cp720]

Please see the pic below. The pool as 4 returns and the spa has 2 for a total of 6 returns from the filter. At this moment the 4 pool returns are in a serial run starting with a 2" pipe and ending with a 1" pipe. Each of the 4 pipes that enter the pool are 1". I mentioned to my plumber that I'd like to cut off the last 1" run and connect a 2" pipe all the way back to the original 2" run to create a loop... keeping the 4th return in place through a Tee. He has strong feelings against this because he doesn't think there will be enough pressure to move water in the pool. The suction side is fed by 2 separate 2.5" runs from 2 skimmers. One skimmer is also supporting the main drains.

Will return pressure be a problem if we loop it back? Also, are 1" outlets big enough? It just "feels" undersized, but I don't have science or experience to lean on here.

Thanks all.

[attachment=0:1o9cp720]pool return.jpg[/attachment:1o9cp720]