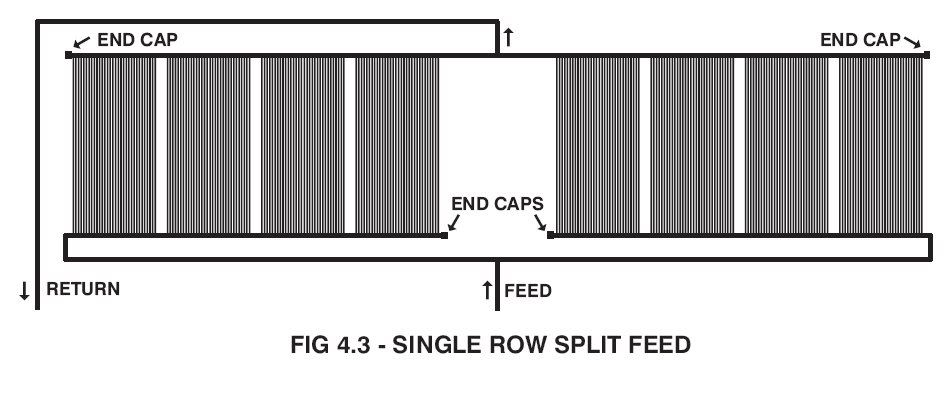

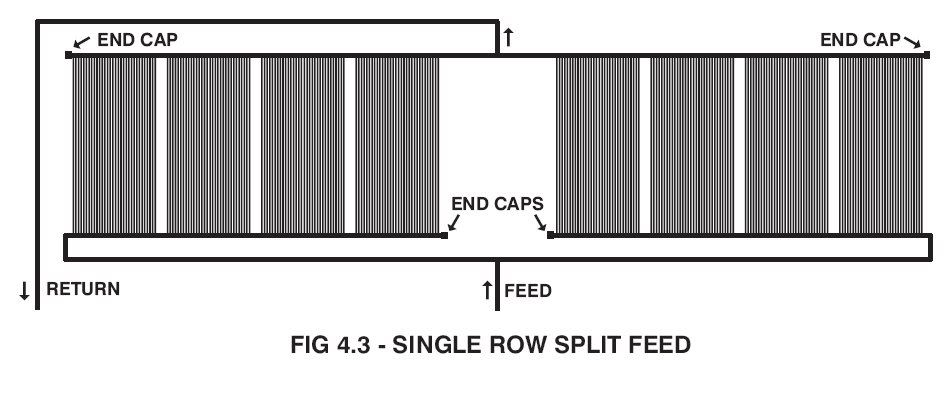

I just got 12 (50sqft) panels installed in 2 sections. 6 panels on the South Facing and 6 on the West. According to the installation panel, there should be 1 split line feeding both panels at the same time and both return line merging into one according to the diagram below.

The installer connected the feed line to one panel, and on the opposite top return line connected into the 2nd panels feed line and then took that panels out line and connected back to the pool. Essentially running the water through 6 panels then flowing it into the next 6 panel. This doesn't seem too efficient. In essence it seems to me that I now have 6 100sqft panels.

Should I have them reroute the piping. My pool temps were as following 1st day after install, water temp 78, air temp 81hi-69low and pool temp at 5pm was 80 degrees, 2nd day water temp 80 ( no heat loss) 82hi- 67low and water temp at 5pm was 81. This morning water temp 78.

Am I over reacting?

The installer connected the feed line to one panel, and on the opposite top return line connected into the 2nd panels feed line and then took that panels out line and connected back to the pool. Essentially running the water through 6 panels then flowing it into the next 6 panel. This doesn't seem too efficient. In essence it seems to me that I now have 6 100sqft panels.

Should I have them reroute the piping. My pool temps were as following 1st day after install, water temp 78, air temp 81hi-69low and pool temp at 5pm was 80 degrees, 2nd day water temp 80 ( no heat loss) 82hi- 67low and water temp at 5pm was 81. This morning water temp 78.

Am I over reacting?