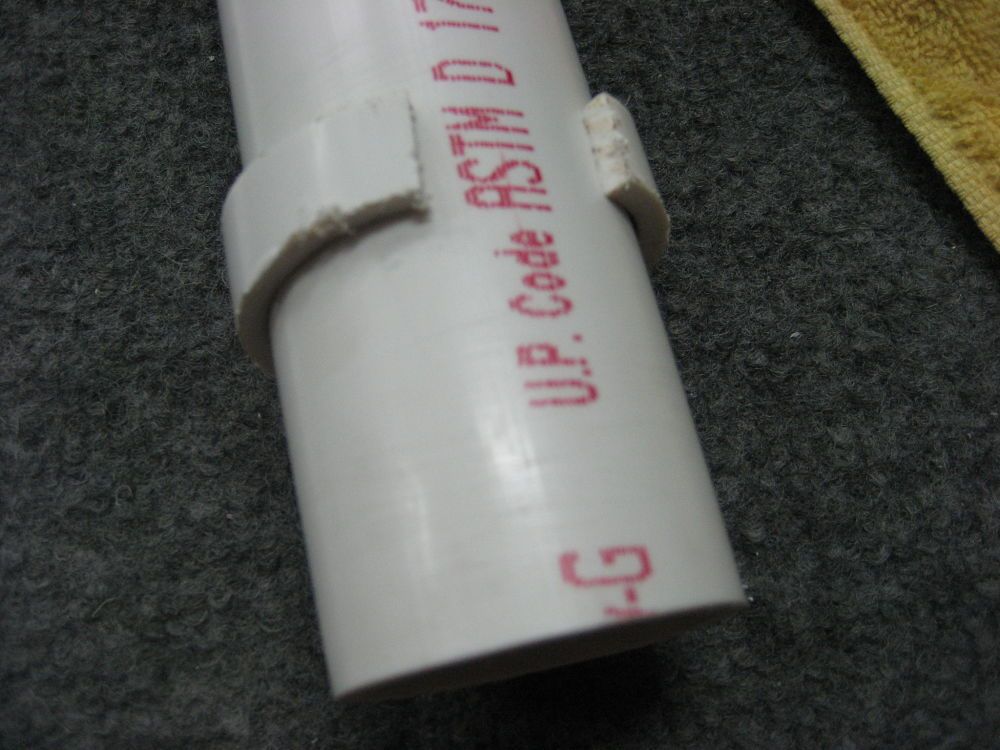

After reading about this simple project here at TFP I decided to make one of these pool coolers. I made my first version on July 14 similar to the one I have pictured. For my first attempt I used approx. 120 1/8" holes which worked fine but I wanted to improve with a second try.

I extended this version an additional foot to 6 feet and used a 1/16" drill bit to create smaller droplets.

This "How To" will be completed in multiple posts.

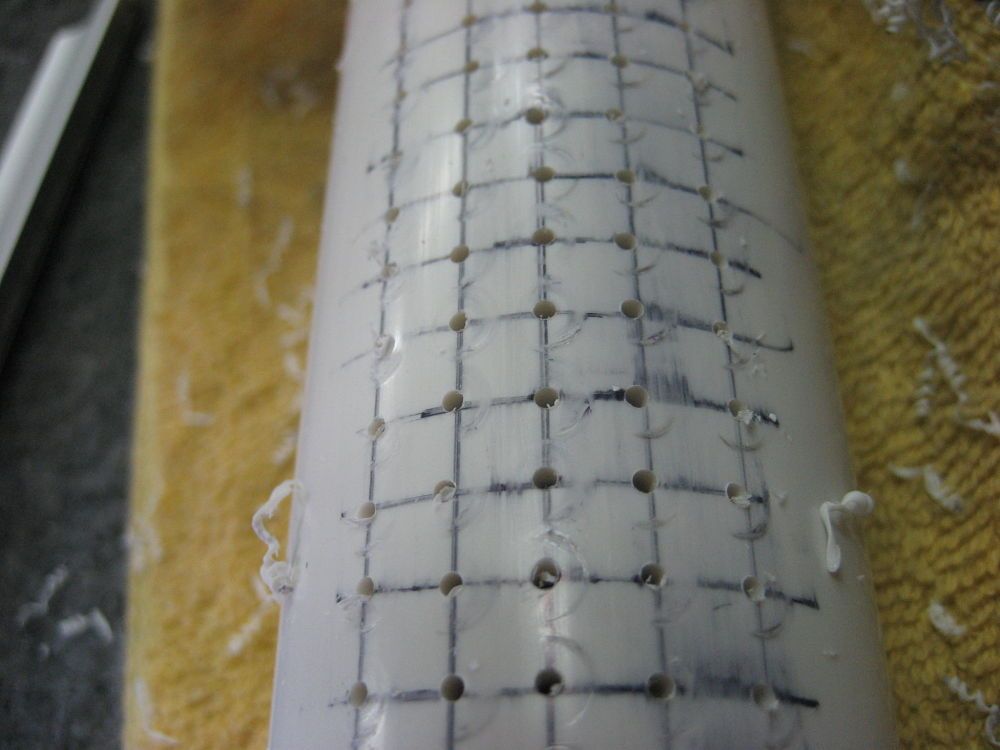

My first step after cutting a 10' piece of 1.5" PVC to 6' was to draw 5 lines 12" long onto the PVC, 1/4" apart. Then I made a pen mark every 1/4" along the length.

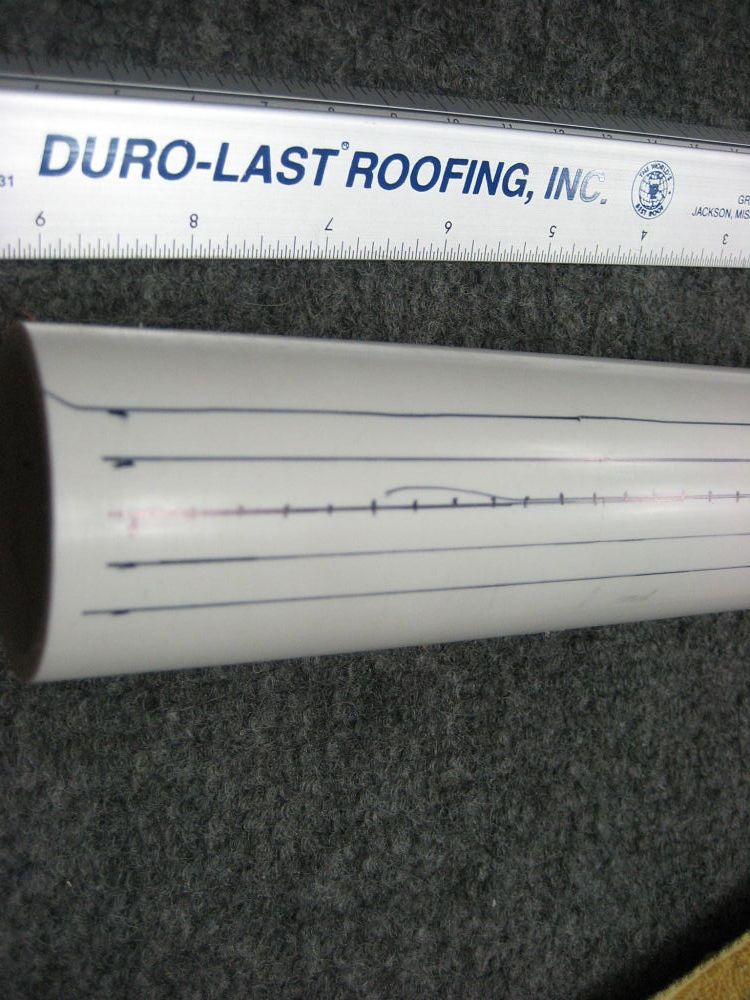

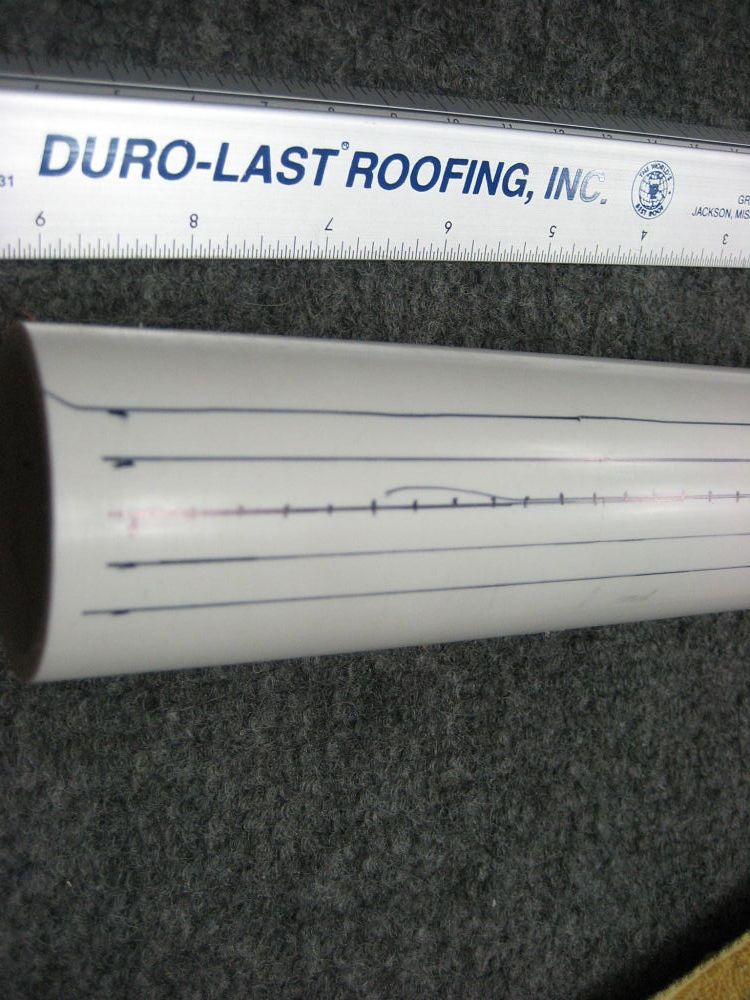

I then used a small piece of the 1.5" pipe to draw the horizontal lines every 1/4". I made one cut in this small piece so that it would stretch around the project piece.

I extended this version an additional foot to 6 feet and used a 1/16" drill bit to create smaller droplets.

This "How To" will be completed in multiple posts.

My first step after cutting a 10' piece of 1.5" PVC to 6' was to draw 5 lines 12" long onto the PVC, 1/4" apart. Then I made a pen mark every 1/4" along the length.

I then used a small piece of the 1.5" pipe to draw the horizontal lines every 1/4". I made one cut in this small piece so that it would stretch around the project piece.