Understanding ORP is the single biggest problem I run into when dealing with new staff. It's not a difficult topic but nobody really offers any training on automated controllers the way training is offered for manual chemistry and pool operation.

First ORP doesn't have anything to do with Chlorine. An ORP sensor has no idea what chlorine is and doesn't react to the presence of chlorine. ORP sensors are used in both Chlorine and Bromine pools. ORP sensors are essentially oxygen sensors - they sense how readily the pool water will let oxygen transfer from one molecule (reduction) to another (oxidation). Chlorine and Bromine do not kill pathogens in pool water, they just act like as a carrier for oxygen which is what does the killing.

Anywhere I mention Chlorine you can pretty much replace the name with Bromine and it's still mostly true.

When chlorine is added to pool water there are two compounds created (that we care about); one is Hypochlorite Ions (OCL-)and the other is Hypochlorous Acid (HOCL).

Hypochlorite ions are "free" chlorine but they are quite stable molecules and don't give up their oxygen very easily. OCL- contributes very little to the germ killing power of your water and is insignificant as part of an ORP value.

Hypochlorous Acid is "free" chlorine and very unstable. HOCL will give up its oxygen at the drop of a hat. It's the main sanitizing compound in the water and constitutes pretty much all of the water's Oxidation/Reduction Potential. Although technically incorrect you can pretty much consider an ORP sensor to be a Hypochlorous Acid sensor as that'll be the only significant oxidizer in your pool.

So your "Free" chlorine kit is showing you both HOCL and OCL- while an ORP controller is only showing you HOCL.

The difference between HOCL and OCL- is a single hydrogen atom. The more "free" hydrogen available in the water the higher the ratio of HOCL to OCL- will be. pH, or "Potential of Hydrogen" is a measure of how readily something will absorb hydrogen. The higher the pH value the more readily the substance will accept hydrogen.

Since Hypochlorous Acid requires OCL- to pick up an H+ the less basic your water is the more hydrogen will be able to bond with OCL- and the more HOCL vs OCL you'll have. The higher your HOCL the higher your ORP value and the more bug killing power you'll have. Free Chlorine, on the other hand, won't necessarily change.

Assuming a spa/hot tub:

- At a pH of 7.0 approximately 75% of the Free chlorine residual is in the form of Hypochlorous acid. So if your FAC is 4.0 then your HOCL is 3.0 and your OCL- is 1.0.

- At a pH of 7.5 approximately 48% of FAC is HOCL and 52% is OCL- so FAC 4.0 means HOCL 1.92 and OCL- 2.08

- At a pH of 8.0 approximately 22% of FAC is HOCL and 78% is OCL- so FAC 4.0 means HOCL 0.88 and OCL- 3.12

If your ORP control is set to 762 mV and your pH is 7.5 then you will have 4.0 PPM FAC and 1.92 PPM HOCL. If you have a PPM vs PH vs ORP chart around you'll see that's true (7.5 pH # 5 PPM FAC is 768 mV). You can work on the (technically incorrect but operationally OK) assumption that your ORP controller is set to 1.92 PPM HOCL.

If your pH drops to 7.0 then that 1.92 PPM HOCL will increase to 3.0 PPM which is too high and the controller will not feed chlorine again until the HOCL PPM has dropped to 1.92 PPM. For that to happen the FAC has to drop to 2.4 PPM. Why?

At 7.5pH HOCL is 48% of FAC or 1.92. At 7.0 pH there is more hydrogen available and the OCL- will pick it up and become HOCL. in order to drop to 1.92 HOCL you need 1.92 / 75 * 100 FAC = 2.56 PPM

If your pH rises to 8.0 then that 1.92 PPM HOCL will drop to 0.88 which is too low and the controller will feed chlorine until it sees 1.92 PPM of HOCL. This requires 8.73 PPM FAC: 1.92 / 22 * 100 = 8.73 PPM

In all cases above the controller has the FAC exactly where it needs to be in order to maintain the same pathogen destroying power. This is exactly what then ORP controller is supposed to do. The "problem" with the sanitizer levels above is the pH, not the FAC.

When doing manual sanitizer control you add the sanitizer then fix the pH after. When you have an automated controller it's kind of opposite. pH MUST be steady and correct before you can turn on the sanitizer system. I can't tell you how many times I've seen people trying to "fix" sanitizer levels that were too high or too low while completely ignoring pH. Heck, I did the same thing for the first couple of years I worked in a pool!

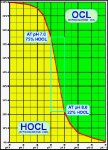

Here's a chart I stole from someplace online that shows the effect of pH on chlorine compounds. I wish I could remember where! It was a good site.

[attachment=0:2f41wkns]ORP vs PPM.JPG[/attachment:2f41wkns]

First ORP doesn't have anything to do with Chlorine. An ORP sensor has no idea what chlorine is and doesn't react to the presence of chlorine. ORP sensors are used in both Chlorine and Bromine pools. ORP sensors are essentially oxygen sensors - they sense how readily the pool water will let oxygen transfer from one molecule (reduction) to another (oxidation). Chlorine and Bromine do not kill pathogens in pool water, they just act like as a carrier for oxygen which is what does the killing.

Anywhere I mention Chlorine you can pretty much replace the name with Bromine and it's still mostly true.

When chlorine is added to pool water there are two compounds created (that we care about); one is Hypochlorite Ions (OCL-)and the other is Hypochlorous Acid (HOCL).

Hypochlorite ions are "free" chlorine but they are quite stable molecules and don't give up their oxygen very easily. OCL- contributes very little to the germ killing power of your water and is insignificant as part of an ORP value.

Hypochlorous Acid is "free" chlorine and very unstable. HOCL will give up its oxygen at the drop of a hat. It's the main sanitizing compound in the water and constitutes pretty much all of the water's Oxidation/Reduction Potential. Although technically incorrect you can pretty much consider an ORP sensor to be a Hypochlorous Acid sensor as that'll be the only significant oxidizer in your pool.

So your "Free" chlorine kit is showing you both HOCL and OCL- while an ORP controller is only showing you HOCL.

The difference between HOCL and OCL- is a single hydrogen atom. The more "free" hydrogen available in the water the higher the ratio of HOCL to OCL- will be. pH, or "Potential of Hydrogen" is a measure of how readily something will absorb hydrogen. The higher the pH value the more readily the substance will accept hydrogen.

Since Hypochlorous Acid requires OCL- to pick up an H+ the less basic your water is the more hydrogen will be able to bond with OCL- and the more HOCL vs OCL you'll have. The higher your HOCL the higher your ORP value and the more bug killing power you'll have. Free Chlorine, on the other hand, won't necessarily change.

Assuming a spa/hot tub:

- At a pH of 7.0 approximately 75% of the Free chlorine residual is in the form of Hypochlorous acid. So if your FAC is 4.0 then your HOCL is 3.0 and your OCL- is 1.0.

- At a pH of 7.5 approximately 48% of FAC is HOCL and 52% is OCL- so FAC 4.0 means HOCL 1.92 and OCL- 2.08

- At a pH of 8.0 approximately 22% of FAC is HOCL and 78% is OCL- so FAC 4.0 means HOCL 0.88 and OCL- 3.12

If your ORP control is set to 762 mV and your pH is 7.5 then you will have 4.0 PPM FAC and 1.92 PPM HOCL. If you have a PPM vs PH vs ORP chart around you'll see that's true (7.5 pH # 5 PPM FAC is 768 mV). You can work on the (technically incorrect but operationally OK) assumption that your ORP controller is set to 1.92 PPM HOCL.

If your pH drops to 7.0 then that 1.92 PPM HOCL will increase to 3.0 PPM which is too high and the controller will not feed chlorine again until the HOCL PPM has dropped to 1.92 PPM. For that to happen the FAC has to drop to 2.4 PPM. Why?

At 7.5pH HOCL is 48% of FAC or 1.92. At 7.0 pH there is more hydrogen available and the OCL- will pick it up and become HOCL. in order to drop to 1.92 HOCL you need 1.92 / 75 * 100 FAC = 2.56 PPM

If your pH rises to 8.0 then that 1.92 PPM HOCL will drop to 0.88 which is too low and the controller will feed chlorine until it sees 1.92 PPM of HOCL. This requires 8.73 PPM FAC: 1.92 / 22 * 100 = 8.73 PPM

In all cases above the controller has the FAC exactly where it needs to be in order to maintain the same pathogen destroying power. This is exactly what then ORP controller is supposed to do. The "problem" with the sanitizer levels above is the pH, not the FAC.

When doing manual sanitizer control you add the sanitizer then fix the pH after. When you have an automated controller it's kind of opposite. pH MUST be steady and correct before you can turn on the sanitizer system. I can't tell you how many times I've seen people trying to "fix" sanitizer levels that were too high or too low while completely ignoring pH. Heck, I did the same thing for the first couple of years I worked in a pool!

Here's a chart I stole from someplace online that shows the effect of pH on chlorine compounds. I wish I could remember where! It was a good site.

[attachment=0:2f41wkns]ORP vs PPM.JPG[/attachment:2f41wkns]