I’ve been trying to figure out my turnover time for my pool and I can’t really come up with a number. I know the rule of thumb on this forum is to set the pump time higher and then gradually decrease the time window as long as the water stays clear and sparkling. The problem for me is that â€clear and sparkling†is somewhat subjective and this being my first full season I’m not sure I can trust my judgment on this.

I have a 27k in-ground pool I have a Hayward Superpump with the following on the nameplate:

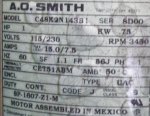

C48K2N143B1 SP-1607-Z1-M series 8D00 1HP, SF 1.1, 3450 RPM, 0.75KWt (see pic below)

It appears that this model is discontinued and looking at the current superpump lineup on Hayward site the closest current model is SP2607X1.

I have two intake lines (skimmer and MD) merging into on 1-1/2†pipe before pipe, DE filter (model in my signature) and then one 1-1/2†return pipe splitting into three 1-1/2†pipes going to the return jets. Doing some repiping I discovered some water in one of the 3 return pipes. The equipment pad is on the level with the pool and is 5 feet away. I would estimate skimmer and MD lines to be 25-30 feet each. The return lines are about 50, 50 and 60. No water features.

I looked at the hydraulics 101 post and pump basics post. The GPM estimate XLS from the first post doesn’t have my pump model and I tried to plug-in my numbers as much as it made sense, but it seemed that I was lacking too much input data.

The pump basics post has a simple table for turnover time per give volume and HP:

HP SFHP BEP GPM BEP Head Pool Volume (8hr Turnover)

0.5 1.05 62 37 29,616

0.75 1.39 67 51 32,168

1 1.85 85 58 40,850

1.5 2.40 102 59 48,965

2 2.70 121 61 57,893

3 4.80 148 76 70,804

My pump being 1HP and my pool being 27k, it seems that a good estimate for my turnover time would be slightly more than 5 hours. Which seems a little low. I ran the pump for 6 hours a day last Septmber before I closed the pool, but too be honest I had no idea was I was doing back then. The water seemed to be ok though.

Old owner had the pump running for 12 hours a day, but then he had calcium hardness increaser in the pool shed for the vinyl pool.

Can someone who had a similar size pool and 1HP pump with somewhat similar piping situation tell me their turnover times? Or maybe someone who has a lot of experience to simply estimate the time for my situation?

Thank you a lot, and sorry for the long post ïŠ

I have a 27k in-ground pool I have a Hayward Superpump with the following on the nameplate:

C48K2N143B1 SP-1607-Z1-M series 8D00 1HP, SF 1.1, 3450 RPM, 0.75KWt (see pic below)

It appears that this model is discontinued and looking at the current superpump lineup on Hayward site the closest current model is SP2607X1.

I have two intake lines (skimmer and MD) merging into on 1-1/2†pipe before pipe, DE filter (model in my signature) and then one 1-1/2†return pipe splitting into three 1-1/2†pipes going to the return jets. Doing some repiping I discovered some water in one of the 3 return pipes. The equipment pad is on the level with the pool and is 5 feet away. I would estimate skimmer and MD lines to be 25-30 feet each. The return lines are about 50, 50 and 60. No water features.

I looked at the hydraulics 101 post and pump basics post. The GPM estimate XLS from the first post doesn’t have my pump model and I tried to plug-in my numbers as much as it made sense, but it seemed that I was lacking too much input data.

The pump basics post has a simple table for turnover time per give volume and HP:

HP SFHP BEP GPM BEP Head Pool Volume (8hr Turnover)

0.5 1.05 62 37 29,616

0.75 1.39 67 51 32,168

1 1.85 85 58 40,850

1.5 2.40 102 59 48,965

2 2.70 121 61 57,893

3 4.80 148 76 70,804

My pump being 1HP and my pool being 27k, it seems that a good estimate for my turnover time would be slightly more than 5 hours. Which seems a little low. I ran the pump for 6 hours a day last Septmber before I closed the pool, but too be honest I had no idea was I was doing back then. The water seemed to be ok though.

Old owner had the pump running for 12 hours a day, but then he had calcium hardness increaser in the pool shed for the vinyl pool.

Can someone who had a similar size pool and 1HP pump with somewhat similar piping situation tell me their turnover times? Or maybe someone who has a lot of experience to simply estimate the time for my situation?

Thank you a lot, and sorry for the long post ïŠ