I'm hoping someone can help me with a problem I'm having using Mark's GPM Estimate v3 spreadsheet. The problem is entirely with me I'm sure, not with the spreadsheet, as I really don't know what I'm doing in Excel.

I recently installed a Hayward EcoStar SP3400 VSP and I'm trying to get an accurate estimate of the gpm so I can program the pump appropriately to get the right turnover rate.

Using the pump's on-board menu I got the wattage at 1000 rpm intervals from 1100 to 3400 rpm and also noted the filter pressure at each speed. I was hoping to enter the information into the spreadsheet and have it propagate the gpm and other info for the various speeds.

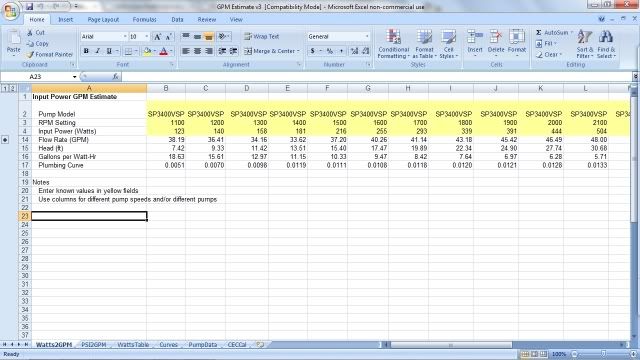

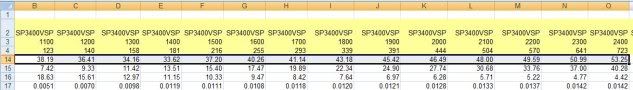

Starting with the Watts2GPM tab I entered the pump model into columns B thru X and then put in the RPM and the input power in the next 2 rows all the way across. The original spreadsheet was only populated with data out to column M, so I copied and pasted the individual cells in the yellow section to populate columns N thru X. I then did the same thing in the PSI2GPM tab. I was hoping that the spreadsheet would then calculate the data for the various rpm ranges, but it doesn't. I'm sure I'm doing something wrong and I was hoping someone could point me in the right direction.

Thanks for any help,

Gary

I recently installed a Hayward EcoStar SP3400 VSP and I'm trying to get an accurate estimate of the gpm so I can program the pump appropriately to get the right turnover rate.

Using the pump's on-board menu I got the wattage at 1000 rpm intervals from 1100 to 3400 rpm and also noted the filter pressure at each speed. I was hoping to enter the information into the spreadsheet and have it propagate the gpm and other info for the various speeds.

Starting with the Watts2GPM tab I entered the pump model into columns B thru X and then put in the RPM and the input power in the next 2 rows all the way across. The original spreadsheet was only populated with data out to column M, so I copied and pasted the individual cells in the yellow section to populate columns N thru X. I then did the same thing in the PSI2GPM tab. I was hoping that the spreadsheet would then calculate the data for the various rpm ranges, but it doesn't. I'm sure I'm doing something wrong and I was hoping someone could point me in the right direction.

Thanks for any help,

Gary