Hello All,

I have to change the bulkheads on my sidemount TR-100 due to a cracked/leaking external spacer. I am not familiar with the inside of it as it came with my house.

Since I only have access to exploded parts lists I am a bit worried about emptying the sand only to find out I cant undo the internal locknut. From the exploded list it appears to be threaded and I am assuming that it is probably really tight.

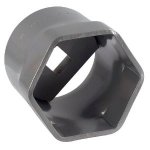

Given the very small opening I don't think I can fit both arms in there to undo the locknut and there is no way that the pipe wrench I have fits in there.

If someone has experience with changing a bulkhead on a TR-100 I would appreciate some insight on how to do it.

Maybe (I hope) I am worrying for no reason.

Thank you for any input

I have to change the bulkheads on my sidemount TR-100 due to a cracked/leaking external spacer. I am not familiar with the inside of it as it came with my house.

Since I only have access to exploded parts lists I am a bit worried about emptying the sand only to find out I cant undo the internal locknut. From the exploded list it appears to be threaded and I am assuming that it is probably really tight.

Given the very small opening I don't think I can fit both arms in there to undo the locknut and there is no way that the pipe wrench I have fits in there.

If someone has experience with changing a bulkhead on a TR-100 I would appreciate some insight on how to do it.

Maybe (I hope) I am worrying for no reason.

Thank you for any input

Luckily they had not glued the pump side.

Luckily they had not glued the pump side.