We have decided to take a leap and freshen-up the back yard. Plans are a pool resurface, deck is undecided, yet will get attention when I sort everything out. I do not want fashioncrete and hope to update the overall look of the pool a little. I'll keep the pics current!!

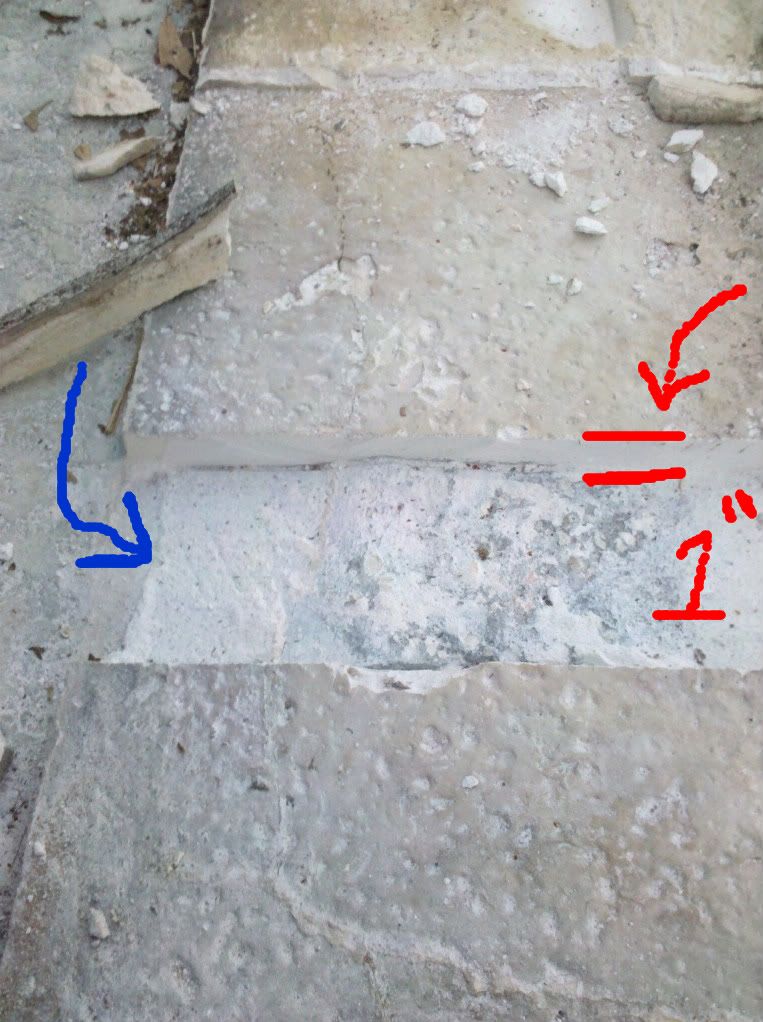

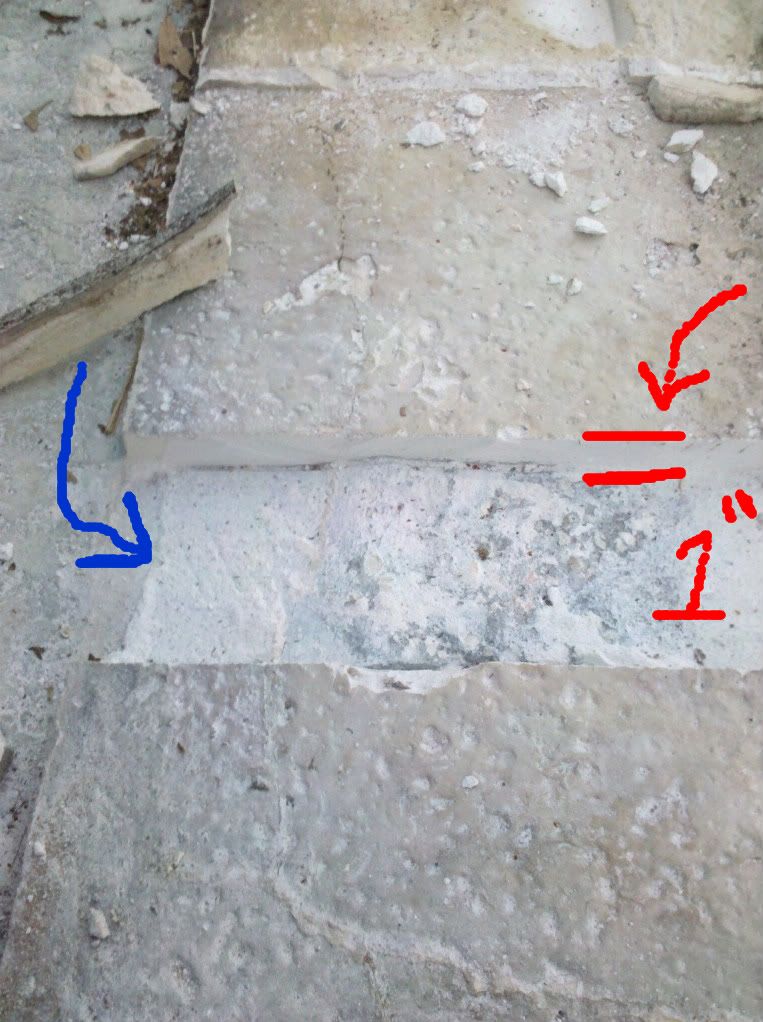

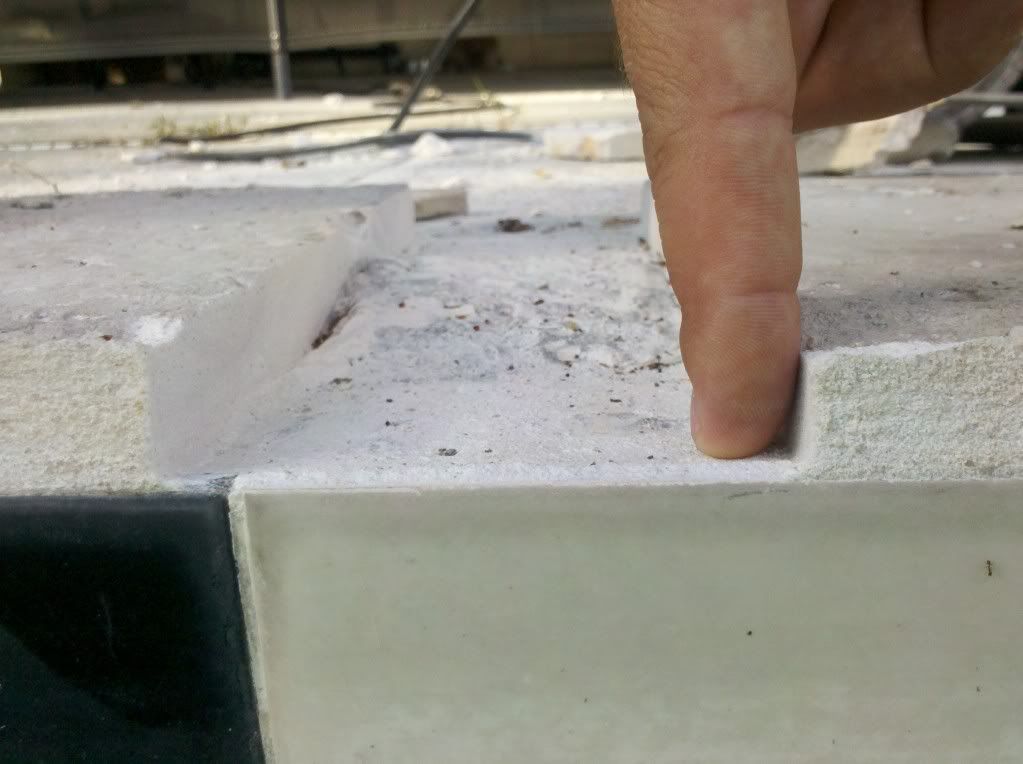

The old coping had to go... It was just too rough and dated! The coping sits on top an INCH of plaster/filler. The top of the coping was 2" above the deck. New deck ideas are flush deck to coping. Looking at thin pavers over the concrete etc...

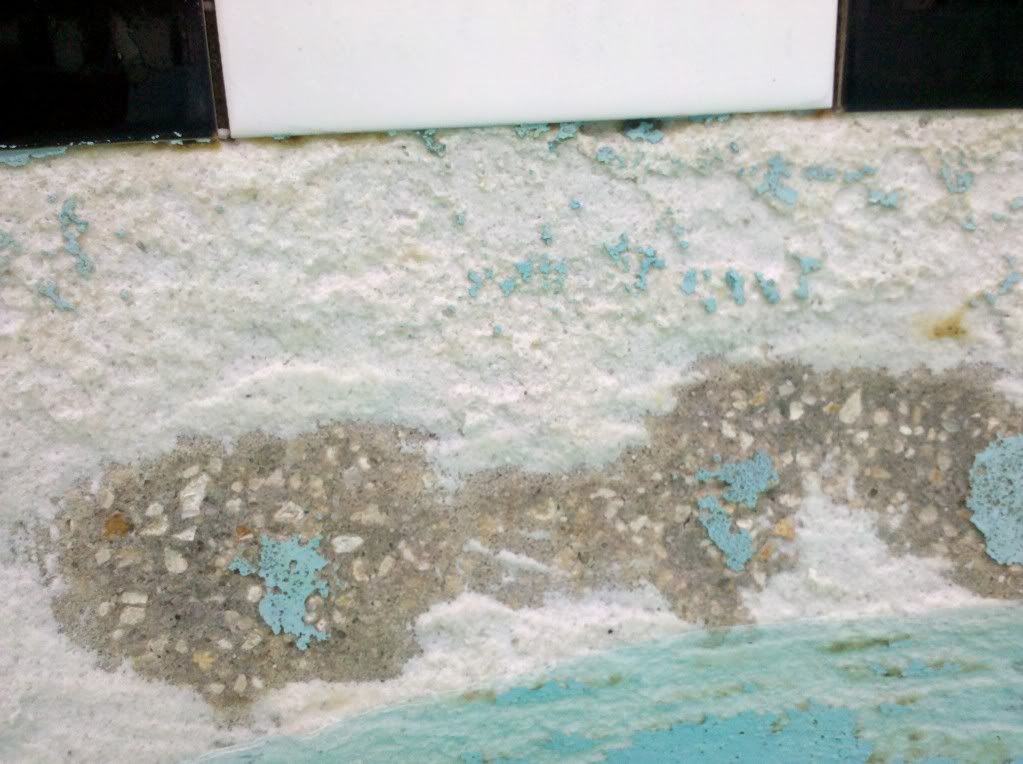

Not sure as to what the final deck is going to be, the pool resurface was put on hold... My existing tile is not bullnosed so I was told that I could either get the deck done first and then do the pool or do the pool and tile resurface, and then risk the tile damage by the coping work (rip out old coping and filler section after new tile was installed). I was also told by a finisher that when my coping was removed a 2"-3" gap would be between the deck and the wall. He felt like we would have to fill with crete and that would be a waste I removed some of the coping sections and cut a slice out of the sub filler (red arrow) and BAM - no gap..!!

This week I will remove all the coping and sub filler - get the whole thing down to a single level/deck level, coping removed. This puts me closer to being able to put the pool guys to work. I also want a NEW RETURN LINE ADDED to plumb my polaris. Right now the booster pump connects to the pool over the sidewall. Still dont have a firm price to move on, but I'm not too worried - this has to be done.

16X32 8ft. deep w/ steps & shelf in deep end. First resurface price was $6500 + 1400 for standard tile. It was only over the phone nothing in writing. I'm shocked at the pros that have not called me back

The old coping had to go... It was just too rough and dated! The coping sits on top an INCH of plaster/filler. The top of the coping was 2" above the deck. New deck ideas are flush deck to coping. Looking at thin pavers over the concrete etc...

Not sure as to what the final deck is going to be, the pool resurface was put on hold... My existing tile is not bullnosed so I was told that I could either get the deck done first and then do the pool or do the pool and tile resurface, and then risk the tile damage by the coping work (rip out old coping and filler section after new tile was installed). I was also told by a finisher that when my coping was removed a 2"-3" gap would be between the deck and the wall. He felt like we would have to fill with crete and that would be a waste I removed some of the coping sections and cut a slice out of the sub filler (red arrow) and BAM - no gap..!!

This week I will remove all the coping and sub filler - get the whole thing down to a single level/deck level, coping removed. This puts me closer to being able to put the pool guys to work. I also want a NEW RETURN LINE ADDED to plumb my polaris. Right now the booster pump connects to the pool over the sidewall. Still dont have a firm price to move on, but I'm not too worried - this has to be done.

16X32 8ft. deep w/ steps & shelf in deep end. First resurface price was $6500 + 1400 for standard tile. It was only over the phone nothing in writing. I'm shocked at the pros that have not called me back

. My thought is this would divide the pool 50/50. Today, the line drops in on the deep end and the Polaris runs the entire pool length. Any reason NOT to place the new port in the center? Beside its going to be a PIA to plumb :blah:

. My thought is this would divide the pool 50/50. Today, the line drops in on the deep end and the Polaris runs the entire pool length. Any reason NOT to place the new port in the center? Beside its going to be a PIA to plumb :blah: