- Aug 27, 2008

- 36

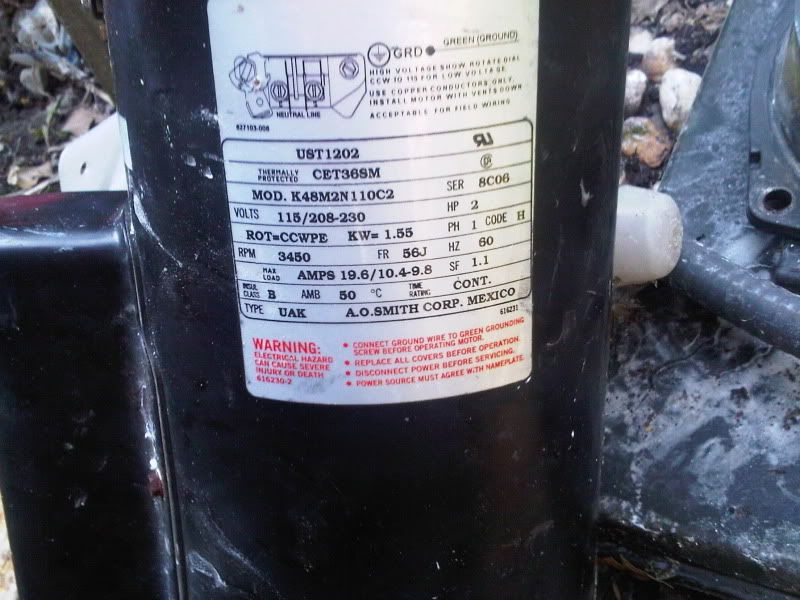

Working on an AO Smith US1202 motor and pump.

It runs but does not pump.

Took it apart and brought to Leslies pools as they do a bench test for free. THey said it is fine but the problem persists.

Here are some pics of what I think the problem is. I cannot find a good picture online of what this is supposed to look like but it looks broken to me. Can anyone tell me if this is broken and if so how I take the broken piece off and replace?

It runs but does not pump.

Took it apart and brought to Leslies pools as they do a bench test for free. THey said it is fine but the problem persists.

Here are some pics of what I think the problem is. I cannot find a good picture online of what this is supposed to look like but it looks broken to me. Can anyone tell me if this is broken and if so how I take the broken piece off and replace?