Howdy all

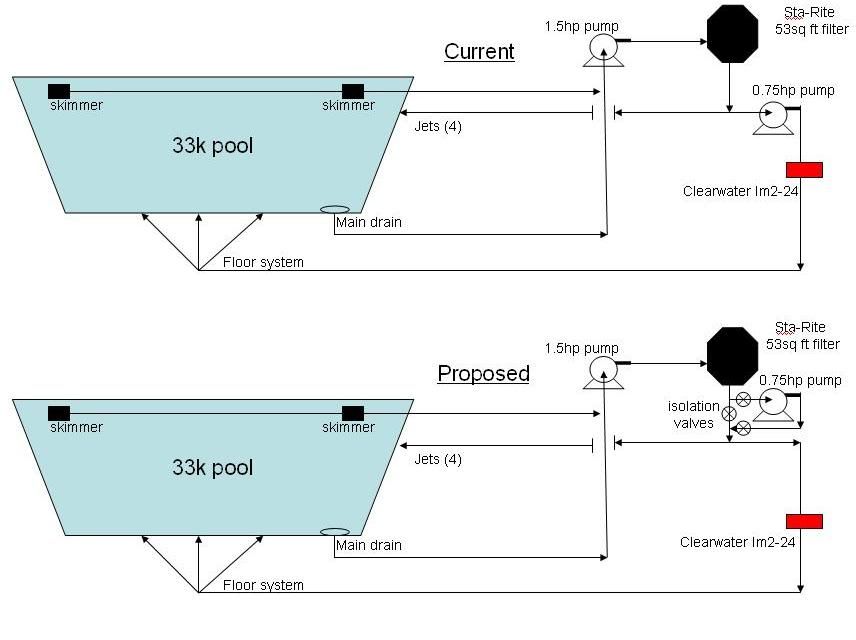

I have a pretty complex system, see below.

The main 1.5hp outlet goes to 2 places: directly to the jets, and through a seconday 0.75hp pump, then the salt cell, then the floor system.

The current system flows kinda weird when both pumps are on. The jets get little flow while the floor system is uber-powerful. I think the 2nd pump was added as a 'booster' when the salt cell was added to the pool 3-4yrs ago.

The flow seems more balanced when the 2nd pump is turned off. Jet pressure is better and the main pump is quieter. Plus I'm saving a bunch of watts.

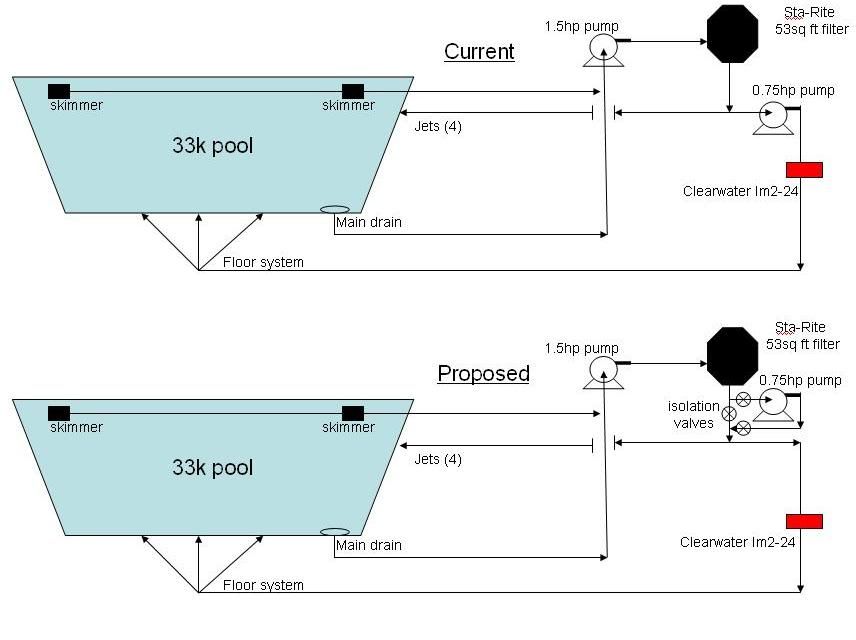

In the interest of 1) running the system longer (needed for the salt cell) 2) saving some utility cost 3) re-balancing the flow, I'm considering re-plumbing the system to take the 'booster' pump out of line, seperated by isolation valves. It could be put back in line as a true booster if/when needed.

What do you think?

-A few other points to consider:

The system (both pumps running) keeps the water clean and sparkly running only 4hrs a day. But this is not enough for the salt cell.

-Salt cell is a bit undersized: clearwater lm2-24 for a 33k pool. It seems to need more like 6hrs minimum to keep Cl levels.

-I've been running the 1.5hp motor only for 6hrs a day for the last several weeks with good results. But salt cell/floor system flow seems kinda low. Taking the 0.75hp pump out of line would help reduce pressure drop and hopefully re-balance the flow.

I have a pretty complex system, see below.

The main 1.5hp outlet goes to 2 places: directly to the jets, and through a seconday 0.75hp pump, then the salt cell, then the floor system.

The current system flows kinda weird when both pumps are on. The jets get little flow while the floor system is uber-powerful. I think the 2nd pump was added as a 'booster' when the salt cell was added to the pool 3-4yrs ago.

The flow seems more balanced when the 2nd pump is turned off. Jet pressure is better and the main pump is quieter. Plus I'm saving a bunch of watts.

In the interest of 1) running the system longer (needed for the salt cell) 2) saving some utility cost 3) re-balancing the flow, I'm considering re-plumbing the system to take the 'booster' pump out of line, seperated by isolation valves. It could be put back in line as a true booster if/when needed.

What do you think?

-A few other points to consider:

The system (both pumps running) keeps the water clean and sparkly running only 4hrs a day. But this is not enough for the salt cell.

-Salt cell is a bit undersized: clearwater lm2-24 for a 33k pool. It seems to need more like 6hrs minimum to keep Cl levels.

-I've been running the 1.5hp motor only for 6hrs a day for the last several weeks with good results. But salt cell/floor system flow seems kinda low. Taking the 0.75hp pump out of line would help reduce pressure drop and hopefully re-balance the flow.