Yep, learned what I needed using my own thread and now the skimmer side of my setup is done. Decided to tackle return side with a fresh mind and today, and next few days, it's rainy. Ugghhh !! Stupid weather, but I have "some" time before the snow flies ....

Finally Plumbed my AGP with PVC

- Thread starter MikeInTN

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MikeInTN said:Coolio. Good luck!

Thanks for your help, everything went well and I think it will hold water .... :lol:

tbird2340

Well-known member

Bump to an old thread.. If anyone that has done this can post some pictures I'd greatly appreciate it.. Thinking about doing mine and need to do so ASAP as I want to get my pool opened soon.

Thanks

Thanks

Here is a ginat Intext link thread that I believe includes what you are looking for. Good luck!

http://www.troublefreepool.com/threads/28539-Useful-links-for-fellow-Intex-Pool-Owners

http://www.troublefreepool.com/threads/28539-Useful-links-for-fellow-Intex-Pool-Owners

tbird2340

Well-known member

Here is a ginat Intext link thread that I believe includes what you are looking for. Good luck!

http://www.troublefreepool.com/threads/28539-Useful-links-for-fellow-Intex-Pool-Owners

Not sure if this was to me or not but I don't have an Intext and I'm looking for some pics of plumbing using PVC like the OP has.

tbird2340

Well-known member

So what do I need to replace all the fittings shown in the pictures here with??

http://imgur.com/a/BNA6m?gallery

Thanks

http://imgur.com/a/BNA6m?gallery

Thanks

Primer (This is used to clean and prep the parts that connect to one another with "slip fittings". You only need to prime the areas that connect to each other. Do not touch or allow anything to contaminate your primered area to ensure a good bond. I usually let the primer dry a couple minutes before glueing. Do not test fit primered parts together. They will stick and possibly not come back apart.)

http://www.lowes.com/pd_23781-138-307560_4294822081_40?productId=1067279

All purpose pvc cement (This is used to glue the parts together. Glue around the pipe and not the fitting and press the pipe into the fitting and twist a little bit. Do not wait long or the glue starts to setup and pressing the parts together gets harder. Once you press them together they will likely not come back apart after 2 seconds. Do not glue or prime any threaded parts. I usually take a rag and wipe off excess glue.)

http://www.lowes.com/pd_23541-138-30821L_0__?productId=4750817

X amount of 1.5" schedule 40 pvc pipe (You will just have to estimate how much pipe you need. They have 5 and 10 foot sections.)

http://www.lowes.com/pd_23840-1814-...=3359594&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" slip on adapter (These will replace the white adapters in your pics. Yours are made to fit a hose and not pipe. You will need at least 5 of them. One on the bottom of the skimmer, one on the return fitting, two on the pump and at least one on the filter. The grey fitting looks bigger, maybe 2", but it will require the same type of adapter whatever size it is.)

http://www.lowes.com/pd_23903-1815-...=3339826&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" 90 degree slip on elbows (You will have to figure out how many you need according to how you want to run your pipe.)

http://www.lowes.com/pd_23909-1815-...=3307896&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" 45 degree slip on elbows (You will probably not need these, but if you do things may get a little more complicated when test fitting them.)

http://www.lowes.com/pd_23894-1815-...=3369494&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" slip on couplings (If you cut a piece of pipe wrong or need to make a pipe longer, these are what is used. You'd better get a few of these.)

http://www.lowes.com/pd_23901-1815-...=3307892&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" slip on unions (These allow you to take your pipe apart easily. If you dont have these then you will have to cut your pipe to remove the pump or filter. I put two on each section on the ends of my plumbing except from the pump to the filter.)

http://www.lowes.com/pd_188223-6930...50160561&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" slip on valves (Put one near the skimmer and one near the return so you can disconnect the pool from the plumbing if you have to work on the pump or filter. I used 1.5" ball valves from Lowes but they tend to stick and the handle can break off leaving you helpless. If you want to do it right get the ones made for pools.)

http://www.sunplay.com/pentair-2-way-pvc-valve-263038

Plumbers tape (Used to seal threaded connections. Wrap around threads 2 to 3 times clockwise with the threads facing you. If you do this the other way the tape can start to peel back when threading the connector in.)

http://www.lowes.com/pd_456833-138-...=4751313&Ns=p_product_qty_sales_dollar|1&pl=1

I suggest you make a drawing of what you want your plumbing to look like before you start. Like the pic in post 1, I suggest you have something for you pipe to sit on like a block to take the weight off the skimmer and return fittings. Sometimes I take a pencil and mark where the fitting goes when test fitting because when test fitting the pipe you cannot press it all the way in or it will be difficult to remove. Also mark a straight line down both the fitting and the pipe so you know you have your angle right. Hope this helps.

http://www.lowes.com/pd_23781-138-307560_4294822081_40?productId=1067279

All purpose pvc cement (This is used to glue the parts together. Glue around the pipe and not the fitting and press the pipe into the fitting and twist a little bit. Do not wait long or the glue starts to setup and pressing the parts together gets harder. Once you press them together they will likely not come back apart after 2 seconds. Do not glue or prime any threaded parts. I usually take a rag and wipe off excess glue.)

http://www.lowes.com/pd_23541-138-30821L_0__?productId=4750817

X amount of 1.5" schedule 40 pvc pipe (You will just have to estimate how much pipe you need. They have 5 and 10 foot sections.)

http://www.lowes.com/pd_23840-1814-...=3359594&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" slip on adapter (These will replace the white adapters in your pics. Yours are made to fit a hose and not pipe. You will need at least 5 of them. One on the bottom of the skimmer, one on the return fitting, two on the pump and at least one on the filter. The grey fitting looks bigger, maybe 2", but it will require the same type of adapter whatever size it is.)

http://www.lowes.com/pd_23903-1815-...=3339826&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" 90 degree slip on elbows (You will have to figure out how many you need according to how you want to run your pipe.)

http://www.lowes.com/pd_23909-1815-...=3307896&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" 45 degree slip on elbows (You will probably not need these, but if you do things may get a little more complicated when test fitting them.)

http://www.lowes.com/pd_23894-1815-...=3369494&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" slip on couplings (If you cut a piece of pipe wrong or need to make a pipe longer, these are what is used. You'd better get a few of these.)

http://www.lowes.com/pd_23901-1815-...=3307892&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" slip on unions (These allow you to take your pipe apart easily. If you dont have these then you will have to cut your pipe to remove the pump or filter. I put two on each section on the ends of my plumbing except from the pump to the filter.)

http://www.lowes.com/pd_188223-6930...50160561&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" slip on valves (Put one near the skimmer and one near the return so you can disconnect the pool from the plumbing if you have to work on the pump or filter. I used 1.5" ball valves from Lowes but they tend to stick and the handle can break off leaving you helpless. If you want to do it right get the ones made for pools.)

http://www.sunplay.com/pentair-2-way-pvc-valve-263038

Plumbers tape (Used to seal threaded connections. Wrap around threads 2 to 3 times clockwise with the threads facing you. If you do this the other way the tape can start to peel back when threading the connector in.)

http://www.lowes.com/pd_456833-138-...=4751313&Ns=p_product_qty_sales_dollar|1&pl=1

I suggest you make a drawing of what you want your plumbing to look like before you start. Like the pic in post 1, I suggest you have something for you pipe to sit on like a block to take the weight off the skimmer and return fittings. Sometimes I take a pencil and mark where the fitting goes when test fitting because when test fitting the pipe you cannot press it all the way in or it will be difficult to remove. Also mark a straight line down both the fitting and the pipe so you know you have your angle right. Hope this helps.

1.5" elbows http://www.homedepot.com/p/Charlott...S-Elbow-PVC023001400HD/203812129?N=5yc1vZbuf5

Connectors http://www.homedepot.com/p/Charlott...Adapter-PVC021091400HD/203811646?N=5yc1vZbuf5

Unions http://www.homedepot.com/p/Homewerk...11-14-112-112B/204202883?N=5yc1vZbuf5Z1z114xb

Also, I noticed in your pictures that the winter cover cable is going around the skimmer box. This is a good way to bend pool walls or crack the skimmer box. The cable should be able to fit between the top rail and the top of the skimmer box.

Connectors http://www.homedepot.com/p/Charlott...Adapter-PVC021091400HD/203811646?N=5yc1vZbuf5

Unions http://www.homedepot.com/p/Homewerk...11-14-112-112B/204202883?N=5yc1vZbuf5Z1z114xb

Also, I noticed in your pictures that the winter cover cable is going around the skimmer box. This is a good way to bend pool walls or crack the skimmer box. The cable should be able to fit between the top rail and the top of the skimmer box.

tbird2340

Well-known member

Also, I noticed in your pictures that the winter cover cable is going around the skimmer box. This is a good way to bend pool walls or crack the skimmer box. The cable should be able to fit between the top rail and the top of the skimmer box.

Thanks for the tip! First time pool owner and this was the first year with the cover.. So the skimmer doesn't get the winter cover around it?

tbird2340

Well-known member

Primer (This is used to clean and prep the parts that connect to one another with "slip fittings". You only need to prime the areas that connect to each other. Do not touch or allow anything to contaminate your primered area to ensure a good bond. I usually let the primer dry a couple minutes before glueing. Do not test fit primered parts together. They will stick and possibly not come back apart.)

http://www.lowes.com/pd_23781-138-307560_4294822081_40?productId=1067279

All purpose pvc cement (This is used to glue the parts together. Glue around the pipe and not the fitting and press the pipe into the fitting and twist a little bit. Do not wait long or the glue starts to setup and pressing the parts together gets harder. Once you press them together they will likely not come back apart after 2 seconds. Do not glue or prime any threaded parts. I usually take a rag and wipe off excess glue.)

http://www.lowes.com/pd_23541-138-30821L_0__?productId=4750817

X amount of 1.5" schedule 40 pvc pipe (You will just have to estimate how much pipe you need. They have 5 and 10 foot sections.)

http://www.lowes.com/pd_23840-1814-...=3359594&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" slip on adapter (These will replace the white adapters in your pics. Yours are made to fit a hose and not pipe. You will need at least 5 of them. One on the bottom of the skimmer, one on the return fitting, two on the pump and at least one on the filter. The grey fitting looks bigger, maybe 2", but it will require the same type of adapter whatever size it is.)

http://www.lowes.com/pd_23903-1815-...=3339826&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" 90 degree slip on elbows (You will have to figure out how many you need according to how you want to run your pipe.)

http://www.lowes.com/pd_23909-1815-...=3307896&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" 45 degree slip on elbows (You will probably not need these, but if you do things may get a little more complicated when test fitting them.)

http://www.lowes.com/pd_23894-1815-...=3369494&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" slip on couplings (If you cut a piece of pipe wrong or need to make a pipe longer, these are what is used. You'd better get a few of these.)

http://www.lowes.com/pd_23901-1815-...=3307892&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" slip on unions (These allow you to take your pipe apart easily. If you dont have these then you will have to cut your pipe to remove the pump or filter. I put two on each section on the ends of my plumbing except from the pump to the filter.)

http://www.lowes.com/pd_188223-6930...50160561&Ns=p_product_qty_sales_dollar|1&pl=1

1.5" slip on valves (Put one near the skimmer and one near the return so you can disconnect the pool from the plumbing if you have to work on the pump or filter. I used 1.5" ball valves from Lowes but they tend to stick and the handle can break off leaving you helpless. If you want to do it right get the ones made for pools.)

http://www.sunplay.com/pentair-2-way-pvc-valve-263038

Plumbers tape (Used to seal threaded connections. Wrap around threads 2 to 3 times clockwise with the threads facing you. If you do this the other way the tape can start to peel back when threading the connector in.)

http://www.lowes.com/pd_456833-138-...=4751313&Ns=p_product_qty_sales_dollar|1&pl=1

I suggest you make a drawing of what you want your plumbing to look like before you start. Like the pic in post 1, I suggest you have something for you pipe to sit on like a block to take the weight off the skimmer and return fittings. Sometimes I take a pencil and mark where the fitting goes when test fitting because when test fitting the pipe you cannot press it all the way in or it will be difficult to remove. Also mark a straight line down both the fitting and the pipe so you know you have your angle right. Hope this helps.

Thanks for taking the time to do this.. I'm sure it will help others as well. I do have all the parts and now I'm just waiting for my new heater to come in so I can get it all plumbed at the same time. I did end up getting those exact slip on valves..

The only real question I have is how many unions to get and where to put them.. I do take my pump in for the winter.. I just cover my filter with a tarp.. Guessing I'll do the same thing with the heater.. So I won't need unions for where those get connected.. Just two at the pump? One where the water is coming in and one where the water is going to the filter? Or should I also have a union right after each valve so I can remove a lot of the piping for the winter?

tbird2340

Well-known member

One more.. Should I install something in the new plumbing setup so I can bypass the heater? Do people generally do that or no?

We take our pipe off also. We have one union right under the skimmer and another union at the front of the pump. Then we have one union between the pump and filter. Then we have a union right after the filter and one union right under the return. So we have 5 unions.

If you just want to remove the filter then you should only need one union at the front of the pump and one somewhere between the pump and filter. Just make sure you put the union in a place to where you can actually get the pump out. An example, our pump is placed on studs in the concrete so we have to lift the pump up about an inch to remove it so the union between the pump and filter is near the filter because the pipe looks like an upside down L shape. If the union was on the vertical part we couldn't remove the pump because the pipe is still in the way.

Since I dont have a heater, I dont know whether or not you should have a bypass. If you think you do then you should go ahead an plumb it in while you can keep your pipe at the proper angles. If you add it later and your pipe isn't square or at 45 degree anlges then you would probably end up with a funky looking section of pipe with a lot of bends in it.

Here is a 3 port pool valve which allows you to turn off one side or turn off both sides or turn on both sides. They are nice to have but are expensive.

http://www.intheswim.com/c/jandy-ne...jHqFBXIYcrYywYI-.its-prd-dal-app-02-p.app1-ha

If you just want to remove the filter then you should only need one union at the front of the pump and one somewhere between the pump and filter. Just make sure you put the union in a place to where you can actually get the pump out. An example, our pump is placed on studs in the concrete so we have to lift the pump up about an inch to remove it so the union between the pump and filter is near the filter because the pipe looks like an upside down L shape. If the union was on the vertical part we couldn't remove the pump because the pipe is still in the way.

Since I dont have a heater, I dont know whether or not you should have a bypass. If you think you do then you should go ahead an plumb it in while you can keep your pipe at the proper angles. If you add it later and your pipe isn't square or at 45 degree anlges then you would probably end up with a funky looking section of pipe with a lot of bends in it.

Here is a 3 port pool valve which allows you to turn off one side or turn off both sides or turn on both sides. They are nice to have but are expensive.

http://www.intheswim.com/c/jandy-ne...jHqFBXIYcrYywYI-.its-prd-dal-app-02-p.app1-ha

This (am at work atm will add the picture or my plumbing when I get home, but here is a link to it at Lowes) is the ball valve that I use on my AGP, I am using 4: 1 just below the skimmer1 1 just before the return to the pool after the filter. 1 between the skimmer and the pump/leaf catcher. and the last one between the return and the filter, this is for a future project or a water feature/to cool the pool.

ok here is the Plumbing from the Skimmer to the pump (including the bypass when we need to dump water due to rain).

here is the plumbing from the filter to the return (including the "new" yet to be installed water feature).

for some reason I could not get Google+ to link to the photos so I included them as a link.

here is the plumbing from the filter to the return (including the "new" yet to be installed water feature).

for some reason I could not get Google+ to link to the photos so I included them as a link.

tbird2340

Well-known member

We take our pipe off also. We have one union right under the skimmer and another union at the front of the pump. Then we have one union between the pump and filter. Then we have a union right after the filter and one union right under the return. So we have 5 unions.

If you just want to remove the filter then you should only need one union at the front of the pump and one somewhere between the pump and filter. Just make sure you put the union in a place to where you can actually get the pump out. An example, our pump is placed on studs in the concrete so we have to lift the pump up about an inch to remove it so the union between the pump and filter is near the filter because the pipe looks like an upside down L shape. If the union was on the vertical part we couldn't remove the pump because the pipe is still in the way.

Since I dont have a heater, I dont know whether or not you should have a bypass. If you think you do then you should go ahead an plumb it in while you can keep your pipe at the proper angles. If you add it later and your pipe isn't square or at 45 degree anlges then you would probably end up with a funky looking section of pipe with a lot of bends in it.

Here is a 3 port pool valve which allows you to turn off one side or turn off both sides or turn on both sides. They are nice to have but are expensive.

http://www.intheswim.com/c/jandy-ne...jHqFBXIYcrYywYI-.its-prd-dal-app-02-p.app1-ha

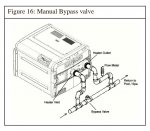

Does it need to be a 3 port? The directions show the below for installing a bypass which would just be a 2 port. Any benefit to using a 3 port and plumbing it differently?

Well lets say you did have a 3 port valve. It would be located where the first "T" is in the pic. You have a few options when turning the 3 port valve.

(1) One selection will allow your water to only go into the heater and not towards the "bypass valve" in the pic therefore blocking that direction.

(2) Another selection will allow your water to only go towards the "bypass valve" and not into the heater therefore blocking that direction.

(3) Another selection will allow your water to go towards the heater and towards the "bypass valve" therefore opening both directions.

I don't see any real benefit of having a 3 port valve there as far as cost goes. I think I would plumb mine up with a 2 port valve like the picture shows if I had a heater. As long as you have valves to separate the pool water from the plumbing then you can still turn them off and work on the heater if something happens.

(1) One selection will allow your water to only go into the heater and not towards the "bypass valve" in the pic therefore blocking that direction.

(2) Another selection will allow your water to only go towards the "bypass valve" and not into the heater therefore blocking that direction.

(3) Another selection will allow your water to go towards the heater and towards the "bypass valve" therefore opening both directions.

I don't see any real benefit of having a 3 port valve there as far as cost goes. I think I would plumb mine up with a 2 port valve like the picture shows if I had a heater. As long as you have valves to separate the pool water from the plumbing then you can still turn them off and work on the heater if something happens.

tbird2340

Well-known member

Well lets say you did have a 3 port valve. It would be located where the first "T" is in the pic. You have a few options when turning the 3 port valve.

(1) One selection will allow your water to only go into the heater and not towards the "bypass valve" in the pic therefore blocking that direction.

(2) Another selection will allow your water to only go towards the "bypass valve" and not into the heater therefore blocking that direction.

(3) Another selection will allow your water to go towards the heater and towards the "bypass valve" therefore opening both directions.

I don't see any real benefit of having a 3 port valve there as far as cost goes. I think I would plumb mine up with a 2 port valve like the picture shows if I had a heater. As long as you have valves to separate the pool water from the plumbing then you can still turn them off and work on the heater if something happens.

Actually, I don't even see how their diagram would work.. If the valve was in the off position, the water would flow up into the heater and then back out.. If it was open, I can see it flowing both up into the heater and straight through.. Right?

Yes some water would still go in the heater but not as fast. The diagram shows a flow meter so maybe they are trying to say an adjustable valve to adjust to get a certain flow rate through the heater to get the most efficiency.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.

Similar threads

- Replies

- 6

- Views

- 404

- Replies

- 23

- Views

- 1K

- Replies

- 6

- Views

- 541

- Replies

- 12

- Views

- 259