What am I missing for my equipment ?

- Thread starter uxbridgechris

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

looks good to me, I saw ur build thread this is a fiberglass shell right? having unions on everything is the best way just make sure to get decent ones the big box stores often have poor quality. Im in cold climate too about to start on mine, I saw ppl using Ts after the 3 way valve with a bushing and plug in it to be able to attach an air fitting to the line to blow them out. Prob what Im gonna do to make winterizing easy peezy, unless you are planning on pulling equipment off pad then u can just blow into plugs in lines.

looks good to me, I saw ur build thread this is a fiberglass shell right? having unions on everything is the best way just make sure to get decent ones the big box stores often have poor quality. Im in cold climate too about to start on mine, I saw ppl using Ts after the 3 way valve with a bushing and plug in it to be able to attach an air fitting to the line to blow them out. Prob what Im gonna do to make winterizing easy peezy, unless you are planning on pulling equipment off pad then u can just blow into plugs in lines.

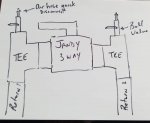

I was thinking the exact same thing. tees, with a ball valve above and a threaded cap with a quick disconnect for my air hose. but was worried that the tee would cause efficiency issues or turbulent water.

Should I have unions on all 3 sides of Jandy 3 way valve?

I'm not going to put unions because u can remove the handy lids and rebuild the valve in place. I figure if it ever comes to it ill dig down and put a coupling underground so pad looks clean. U don't need valve above return lines the 3 way can be closed off individually so u do each return 1 at a time just do Ts on each leg of return. For skimmer I see ppl just lower water level and blow them out in gonna remove my pump for winter I think so I'll so mine w a plug that's custom w air fitting

Pool_Medic

In The Industry

With the SWCG Union, you will have a perfect spot to connect a shop vac or a cyclone blower. Way easier than using a compressor. The same goes for the skimmer side of the pump.

With the SWCG Union, you will have a perfect spot to connect a shop vac or a cyclone blower. Way easier than using a compressor. The same goes for the skimmer side of the pump.

Good point. I was just thinking compressor because my lawn irrigation equipment in right beside pool equipment t and I use compressed air to blow that out.

That would work I'm trying to keep my plumbing tight so street 90s out of the 3way and then the Ts w a threaded bushing on short side and a plug. I use compressor for my irrigation too so easier for me as well but as poolmedic said can use shop vac I just feel its easier to use a fitting and air if u have a decent size compressor

That would work I'm trying to keep my plumbing tight so street 90s out of the 3way and then the Ts w a threaded bushing on short side and a plug. I use compressor for my irrigation too so easier for me as well but as poolmedic said can use shop vac I just feel its easier to use a fitting and air if u have a decent size compressor

My equipment pad is higher than the pool so maybe I am better off using shop vac from the pool returns and skimmer. I do plan on removing pump and putting in house for winter. It will plug into outlet vs hard wired.

- Nov 12, 2017

- 11,848

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Also, what about check valves? do I need one between heater and SWCG?

I just asked that same question in my thread, as I have one right before my SWG and was wondering if I could get rid of it. My SWG installation instructions suggest a straight run of pipe (12" I think) before the SWG. I believe that is to lessen turbulence inside the SWG. Check your SWG instructions for that.

I was told my check before the SWG was a throw back from when there used to be a tab feeder in that location. Tab feeders leach chlorine into the pipe, flow or no, so the check was there to keep that highly concentrated chlorine water from back flowing into the heater, where it would wreck havoc on the heater's internal components. Since an SWG only produces chlorine when the water is flowing, the danger to the heater no longer exists. So I got the green light to remove that check valve.

And I further asked if I needed any checks, as my equipment is all above water level. I was told I didn't need any...

For what it's worth, and some here question this practice as unnecessary, I use sweep 90s wherever I can, to improve flow. There was some experimentation here to determine if they really make a difference. It was somewhat inconclusive. But they just make sense to me... If you decide to use them, be sure they are Schedule 40, as the sweeps you'll find at the big box stores are generally not, they're for waste, not pressure.

I just asked that same question in my thread, as I have one right before my SWG and was wondering if I could get rid of it. My SWG installation instructions suggest a straight run of pipe (12" I think) before the SWG. I believe that is to lessen turbulence inside the SWG. Check your SWG instructions for that.

I was told my check before the SWG was a throw back from when there used to be a tab feeder in that location. Tab feeders leach chlorine into the pipe, flow or no, so the check was there to keep that highly concentrated chlorine water from back flowing into the heater, where it would wreck havoc on the heater's internal components. Since an SWG only produces chlorine when the water is flowing, the danger to the heater no longer exists. So I got the green light to remove that check valve.

And I further asked if I needed any checks, as my equipment is all above water level. I was told I didn't need any...

For what it's worth, and some here question this practice as unnecessary, I use sweep 90s wherever I can, to improve flow. There was some experimentation here to determine if they really make a difference. It was somewhat inconclusive. But they just make sense to me... If you decide to use them, be sure they are Schedule 40, as the sweeps you'll find at the big box stores are generally not, they're for waste, not pressure.

Awesome info, thanks.

Here in Canada we have a hard time getting a selection of PVC as it is not commonly used. I ordered all kinds of fittings from a US dealer. I don't have sweep 90's but a pair of street 45's are almost as good.

I'm looking forward to plumbing my pad to be honest. I plan on doing a lot of heat bending of 2" pvc just because it looks awesome vs using fittings. hahaha

- Nov 12, 2017

- 11,848

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Awesome info, thanks.

Here in Canada we have a hard time getting a selection of PVC as it is not commonly used. I ordered all kinds of fittings from a US dealer. I don't have sweep 90's but a pair of street 45's are almost as good.

I'm looking forward to plumbing my pad to be honest. I plan on doing a lot of heat bending of 2" pvc just because it looks awesome vs using fittings. hahaha

Ooh, heat bending. I like the sound of that for flow!

Two 45s were part of the regular vs sweep experiment. If I remember right they didn't fair so well. You might try a search for that study here on TFP if you're interested. I don't remember all the details. I found sweep 90s on pool store websites. Can they ship up there?

I should mention: some heater manufacturers require the use of a check valve after the heater for warranty compliance. This was likely also a throwback to when tab feeders were the common installation. And maybe heater manufacturers haven't altered that requirement for SWG, or don't agree with SWG being less of a threat. No matter, check your heater's install directions and warranty about that check valve. My heater is out of warranty, so that's how I determined, in part, that my check wasn't needed.

That would work I'm trying to keep my plumbing tight so street 90s out of the 3way and then the Ts w a threaded bushing on short side and a plug. I use compressor for my irrigation too so easier for me as well but as poolmedic said can use shop vac I just feel its easier to use a fitting and air if u have a decent size compressor

Just FYI - streets are the king flow chokers..

(I’m not saying I don’t use them, sometimes I just don’t have room to do otherwise.)

- Nov 12, 2017

- 11,848

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

It's coming back to me! Slowly...

The PVC elbow flow experiment wasn't TFP's, but rather a thread here referenced it. The same thread had some posts warning about the test setup, which could affect the validity of the results, but as the experiment confirmed my own instinct about it, I decided to accept the results and that it was worth a little extra dough to go with sweeps. Here's the TFP conversation about it:

90 degree elbows or 45s?

And here's the experiment:

Do Different PVC Fittings Really Make a Difference in Water Flow? - POND Trade Magazine

You can decide for yourself, of course...

The PVC elbow flow experiment wasn't TFP's, but rather a thread here referenced it. The same thread had some posts warning about the test setup, which could affect the validity of the results, but as the experiment confirmed my own instinct about it, I decided to accept the results and that it was worth a little extra dough to go with sweeps. Here's the TFP conversation about it:

90 degree elbows or 45s?

And here's the experiment:

Do Different PVC Fittings Really Make a Difference in Water Flow? - POND Trade Magazine

You can decide for yourself, of course...

I fast forwarded thru the page but looks like the pair of 45's were not that far behind the sweep elbow. With standard elbow coming last.

I'm not too concerned either way. I have hardly any fittings in my system and the accumulative effect results in nothing to worry about.

Thanks for the link

I'm not too concerned either way. I have hardly any fittings in my system and the accumulative effect results in nothing to worry about.

Thanks for the link

- Nov 12, 2017

- 11,848

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

So my 3/4hp pump is 1.5". I have 2" line going to it and I will be using 2" to plumb the whole system right to the 3 way where it will be bushed down to 1.5" as my 2 returns are 1.5"

Heat bending will be cool.

Heat bending will be cool.

I don't have PoolguyinCt money.

I will use a big torch.

- Nov 12, 2017

- 11,848

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

What keeps the inner diameter round in the bend? Is there a form you bend around? Like you'd do with metal conduit? Or does the PVC just retain its round diameter on its own?

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.