As some of you may know by know I'm installing my own pool, and I'm doing a lot myself. And I post a lot. lol.

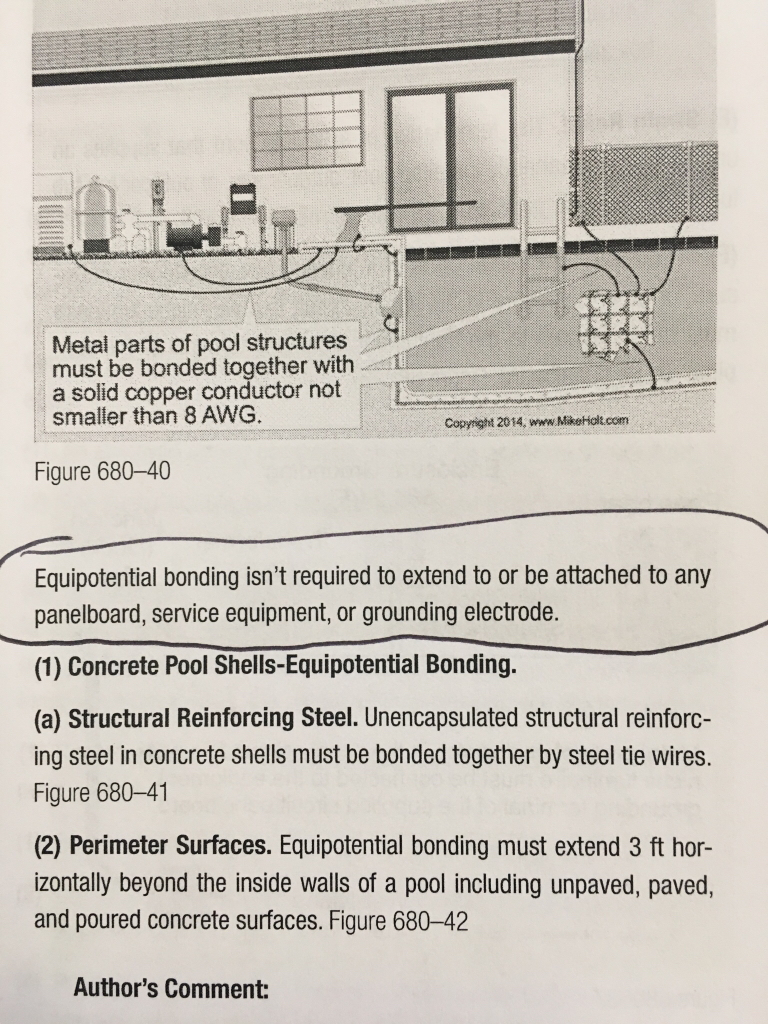

I'm running the electrical connections tonight, and I keep seeing this same statement that befuddles me.

"Never ground pool pump to Power Center"

http://www.pentairpoolme.com/uploads/document/file/540/Manual_IntelliChlor.pdf

The Pentair SWG Power Center has 2 lugs for grounding: one inside for the electrical connection and 1 outside for the bonding connection. (Yes, I understand the the difference between grounding and bonding)

Figure 1 - Pentair SWG Power Center

So, obviously the top left Ground leg, connects to the Ground wire coming from the Branch Circuit (really the Intermatic T104R Timer in my case). But, the Common Bonding Lug (bottom of picture above (Figure 1), external to enclosure) connections to the bonding wire coming from the pool AND is connected to the bonding lug on the bottom of the pump, right? See example setup figure 2.

Figure 2 - SWG to Pump Bonding Diagram

I think I might be reading into the documentation too much, but I think what they are trying to say is [don't connect the "internal lug" of the SWG to the external bonding lug on the pump.

Am I crazy?

(Edit: Updated Figure 2 to include Ground and Bonding lines)

I'm running the electrical connections tonight, and I keep seeing this same statement that befuddles me.

"Never ground pool pump to Power Center"

http://www.pentairpoolme.com/uploads/document/file/540/Manual_IntelliChlor.pdf

The Pentair SWG Power Center has 2 lugs for grounding: one inside for the electrical connection and 1 outside for the bonding connection. (Yes, I understand the the difference between grounding and bonding)

Figure 1 - Pentair SWG Power Center

So, obviously the top left Ground leg, connects to the Ground wire coming from the Branch Circuit (really the Intermatic T104R Timer in my case). But, the Common Bonding Lug (bottom of picture above (Figure 1), external to enclosure) connections to the bonding wire coming from the pool AND is connected to the bonding lug on the bottom of the pump, right? See example setup figure 2.

Figure 2 - SWG to Pump Bonding Diagram

I think I might be reading into the documentation too much, but I think what they are trying to say is [don't connect the "internal lug" of the SWG to the external bonding lug on the pump.

Am I crazy?

(Edit: Updated Figure 2 to include Ground and Bonding lines)