Hello fellow DIY'ers. Hoping one of you can help

My pool pump motor kept blowing a fuse on my Hayward PSC 2100 and blew the board. Not finding any repair or replacement parts for the ol' 2100, I was forced to replace it with a Prologic pl ps8. Apparently the problem was the pump motor, not the psc2100 and the motor finally died. It was a SPX1615Z1MNS, which lasted just two years!!!

I've purchased the replacement motor, but I decided to upsize and go with a two speed. I went with the SPX 1620Z2MNS.

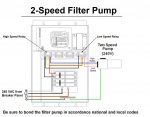

My question is how do I wire this motor differently so that I get to enjoy the benefits of two speeds. I understand I have to use a second relay, but wondering if anyone has pictures of what this looks like. I'm looking at the installation manual, but I can't seem to be able to transfer this to the actual wiring in my prologic box.

Any help would be appreciated. Thanks

Mike- IslandBoy

My pool pump motor kept blowing a fuse on my Hayward PSC 2100 and blew the board. Not finding any repair or replacement parts for the ol' 2100, I was forced to replace it with a Prologic pl ps8. Apparently the problem was the pump motor, not the psc2100 and the motor finally died. It was a SPX1615Z1MNS, which lasted just two years!!!

I've purchased the replacement motor, but I decided to upsize and go with a two speed. I went with the SPX 1620Z2MNS.

My question is how do I wire this motor differently so that I get to enjoy the benefits of two speeds. I understand I have to use a second relay, but wondering if anyone has pictures of what this looks like. I'm looking at the installation manual, but I can't seem to be able to transfer this to the actual wiring in my prologic box.

Any help would be appreciated. Thanks

Mike- IslandBoy