I have read and searched about everything having to do with closing an inground pool. I hope these questions are not answered and I just overlooked them in the many post I have been reading. I live in the Upstate of SC and the winters here are not terrible but we do have times of freezing. I have a solid Loop Loc cover and the info I received from the company suggest not to lower the water more than 12" below the top of the pool. This does not allow me to lower the water below the returns. With that said this is my plan... and then my questions below that....

Allow water to drop below 60 degrees

Bring pool to slam levels and allow to drift back down about halfway

Add Polyquat 60 and let circulate for 1 hour

Drain water level to just below the skimmer

Remove skimmer and pump baskets

Remove return eyeballs

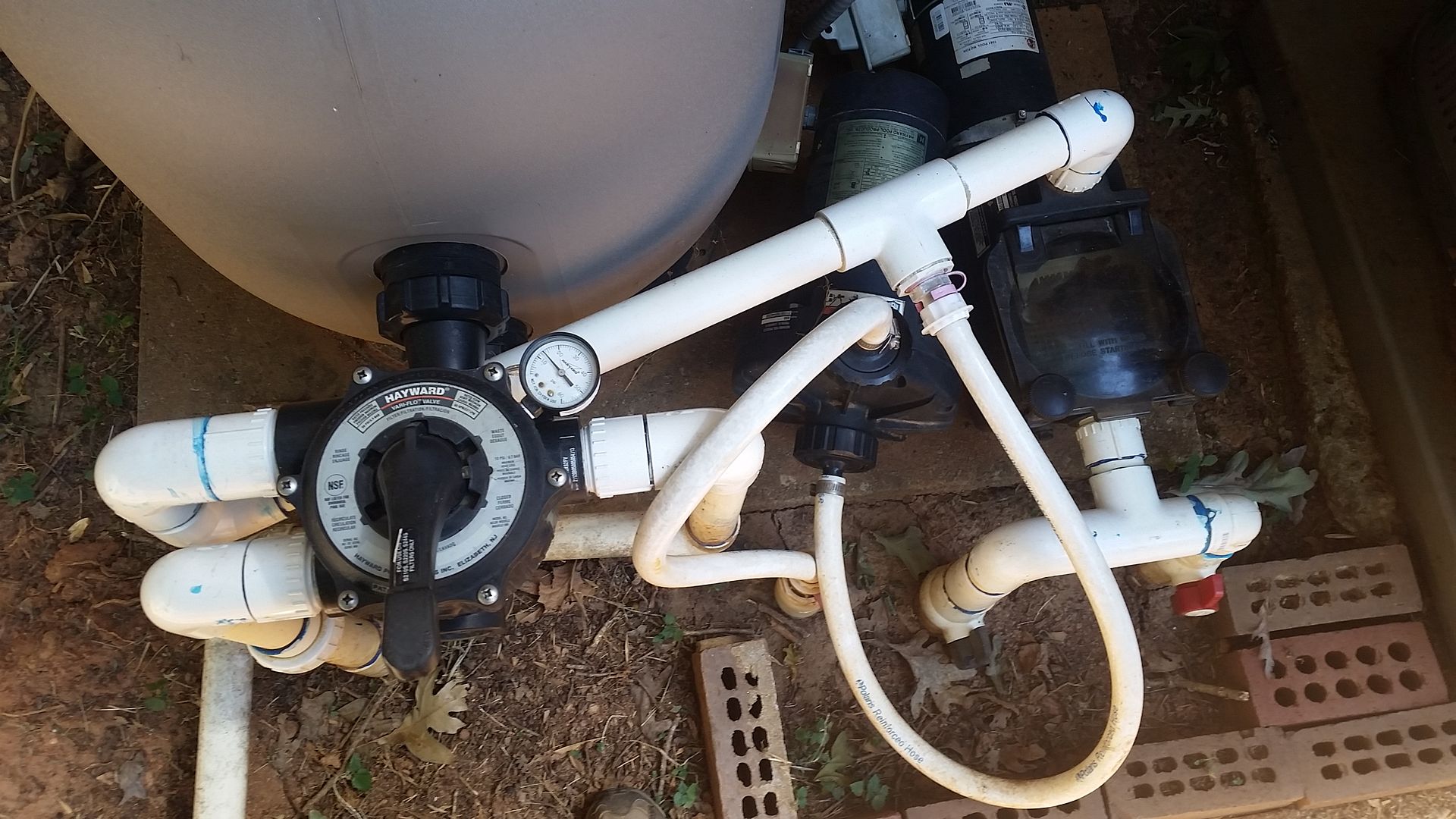

Set sand filter to Recirculate and blow out the skimmer

Continue blowing air until the returns are only blowing out air and plugged off

Finally allow air to blow thru the main drain and shut off the valve

Remove drain plug from sand filter and pump basket

Add Pool/RV antifreeze to skimmer line and return lines

Now for the questions....

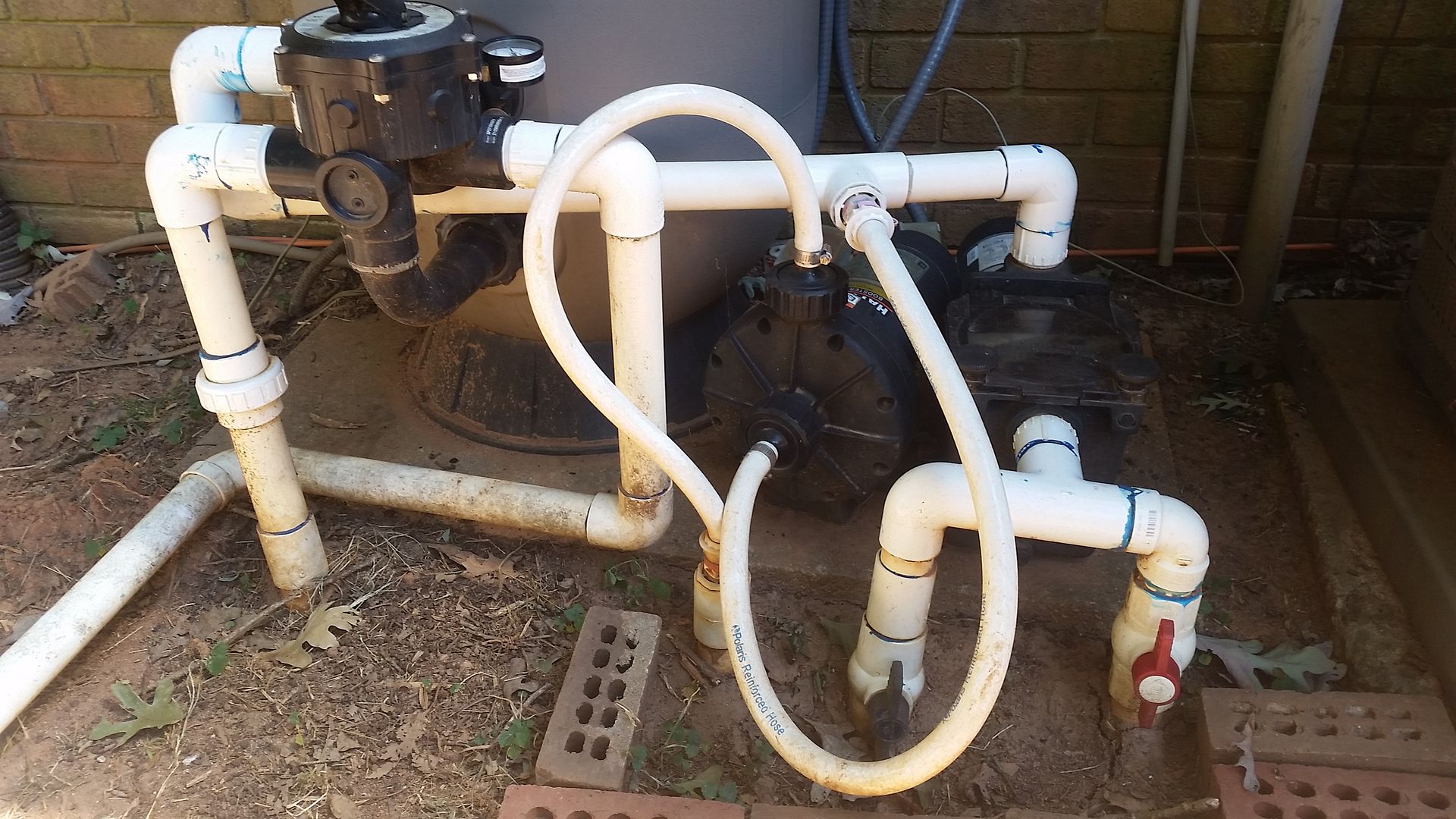

I only have two valves, one valve for the main drain and one valve for the skimmer.

When I blow out the returns do I turn off the main drain?

Do I blow air from the skimmer back into the system using a shop vac?

Where do I add the antifreeze, at the skimmer?

Would it be better to use an air compressor to blow the lines out from the pump basket? If so, How do you keep from blowing the lines apart? I watched several videos about it but no one says anything about it building up pressure. I know I would blow the skimmer and returns out first and then the main drain. Once everything it plugged and the main drain valve is turned off will it build enough pressure to harm anything before you have time to shut the compressor off? What would be a good PSI to be running the compressor at?

If I am missing anything please let me know as I am willing to learn! I water is currently 76 degrees so not much swimming going on and its motivated me to get my head wrapped around the closing process.

Allow water to drop below 60 degrees

Bring pool to slam levels and allow to drift back down about halfway

Add Polyquat 60 and let circulate for 1 hour

Drain water level to just below the skimmer

Remove skimmer and pump baskets

Remove return eyeballs

Set sand filter to Recirculate and blow out the skimmer

Continue blowing air until the returns are only blowing out air and plugged off

Finally allow air to blow thru the main drain and shut off the valve

Remove drain plug from sand filter and pump basket

Add Pool/RV antifreeze to skimmer line and return lines

Now for the questions....

I only have two valves, one valve for the main drain and one valve for the skimmer.

When I blow out the returns do I turn off the main drain?

Do I blow air from the skimmer back into the system using a shop vac?

Where do I add the antifreeze, at the skimmer?

Would it be better to use an air compressor to blow the lines out from the pump basket? If so, How do you keep from blowing the lines apart? I watched several videos about it but no one says anything about it building up pressure. I know I would blow the skimmer and returns out first and then the main drain. Once everything it plugged and the main drain valve is turned off will it build enough pressure to harm anything before you have time to shut the compressor off? What would be a good PSI to be running the compressor at?

If I am missing anything please let me know as I am willing to learn! I water is currently 76 degrees so not much swimming going on and its motivated me to get my head wrapped around the closing process.