I am trying to learn about what valves control everything, above is the return side. Right after the SWG, there is a manual valve then a loop on the left side which also has a check valve then a automated valve. On the right of the automated valve there is two return pipes with another manual valve.

So I am guessing that since I have full automation to control the pool spa that the left side of the automated valve is the SPA return and the right side is the pool return. I also have a deep heat return which I am guessing is the reason I have a manual valve on the pool return side to adjust the flow volume of pool return water between the deep return and the pool wall returns. Sound right?

what's the purpose of the manual valve before the automated valve, the one near the SWG?

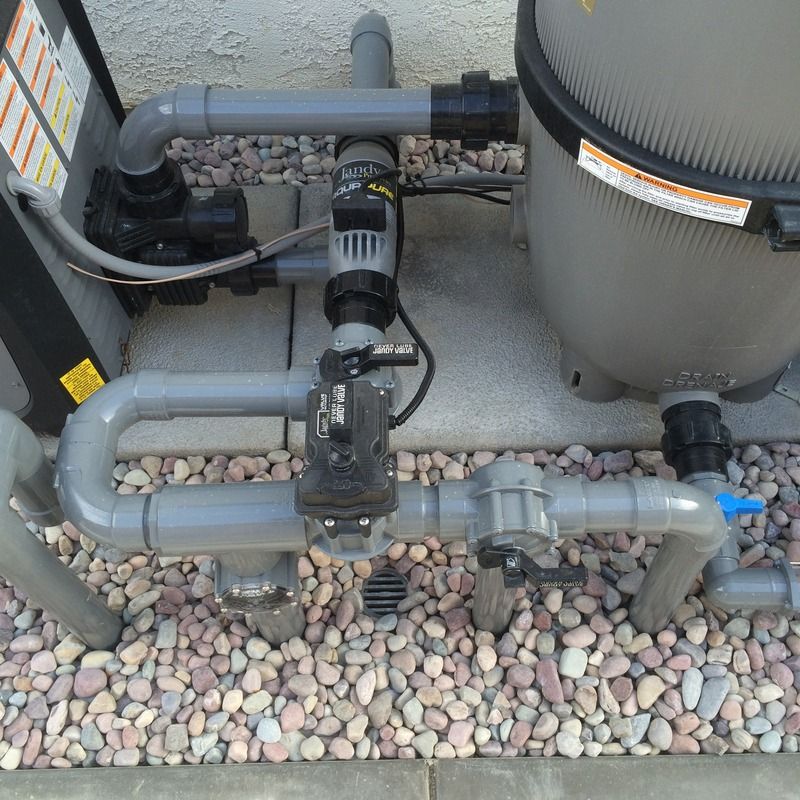

Picture of the suction side:

I figure the automated valve off the pump controls Pool and Spa suction, looks to me like the left side is Spa, and the right side is the pool main drains/skimmer (they are tied together) and the manual valve on the right side is for the robot cleaning port?

just want to get in-front of all of this.

thanks!