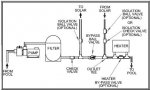

I've decided to get (6) SunHeater S601 Panels to add to my pool. That number of panels will equal about 43% of my pool surface. I will be installing them on racks on the ground next to the building that houses my filter and pump. This will put the racks approx 10' from the pump. I gimp'd the 'system layout' diagram from the S601 install manual to represent how I'd like to plumb them. Does anyone see any problems with this? I believe this plumbs them in parallel, which I understand to be the most efficient way. Will my 1.5hp superpump have enough power to get the correct flow through these? I also notice that the install manual only uses a 3-way valve. Most of the diagrams I've seen here show the 3-way, 2 isolation valves, and a bypass valve. Should I modify my plumbing plans to incorporate the isolation and bypass valves?

[attachment=0:xqnfyeqt]solar diagram rev1.gif[/attachment:xqnfyeqt]

How can I calculate exactly how large the rack should be? It obviously will be at least 12'x40' to accommodate the panels, but how much extra space should I allow for around the panels? How deep into the ground should the 4x4s that support the rack be? Do I need to fill around them with concrete? At what angle should the rack be installed?

I've seen a few diagrams for building a rack and most of them show 1x4's placed about 2 feet apart on the surface of the rack to support the panels. Would there be any benefit to surfacing the rack with 1/2" plywood (to insulate the back of the panels more) and painting it a dark color to help absorb heat from the sun?

Any thought or suggestions on the entire setup would be appreciated.

[attachment=0:xqnfyeqt]solar diagram rev1.gif[/attachment:xqnfyeqt]

How can I calculate exactly how large the rack should be? It obviously will be at least 12'x40' to accommodate the panels, but how much extra space should I allow for around the panels? How deep into the ground should the 4x4s that support the rack be? Do I need to fill around them with concrete? At what angle should the rack be installed?

I've seen a few diagrams for building a rack and most of them show 1x4's placed about 2 feet apart on the surface of the rack to support the panels. Would there be any benefit to surfacing the rack with 1/2" plywood (to insulate the back of the panels more) and painting it a dark color to help absorb heat from the sun?

Any thought or suggestions on the entire setup would be appreciated.