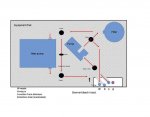

View attachment equipment pad.pdfMy prior equipment pad consisted of a single speed pump, a propane heater, and a Sta-Rite System 3 cartridge filter. I wanted to replace the SS pump with a variable speed (got a great price on the Pentair VSXF pump). I am adding a 23kW solar array and wanted to move to an electrical heat pump rather than propane. I needed to replace the filters of my existing system and found that the replacement filters cost (~$450) nearly as much a new clean and clear system ($600) that enjoys multiple after-market filter options. Hence, I decided to replace the whole enchilada in one fell swoop. I also decided that it wouldn't be that complicated to re plumb such a system (suction, return, waste--bottom drain is not working), so I planned to do it on my own. This is my proposed layout (see below). The filter has inlet/outlet ports on the same side but "in" is above "out"; the heat pump calls for a bypass loop for anything greater than 1 hp (the VSXF is 3 hp) but I only intend to run it at sufficient speed to satisfy the heat pump (25-35 gpm). I probably don't "need" the bypass loop, but decided it couldn't hurt if there was ever a need to increase flow that exceeded the heat pump's limits. The bottom drain was deemed "blocked" by the crew that closed the pool while we were still under the former owner's contract (not sure why, but not sure it matters). I've decided to cap the bottom drain for now unless there are compelling reasons not to do so. We have a Dolphin triton plus bot that can stir things up from the bottom at least a couple times a week. I'm keeping a "pump to waste" function intact as that will come in handy when there is a large debris load in the pool (right?). Any obvious things I'm missing? Does this look logical? I hope to plumb this all together in the next week with deep socket schedule 40 pipe and fittings.

Many thanks for any thoughts or advice!

Jay

Many thanks for any thoughts or advice!

Jay