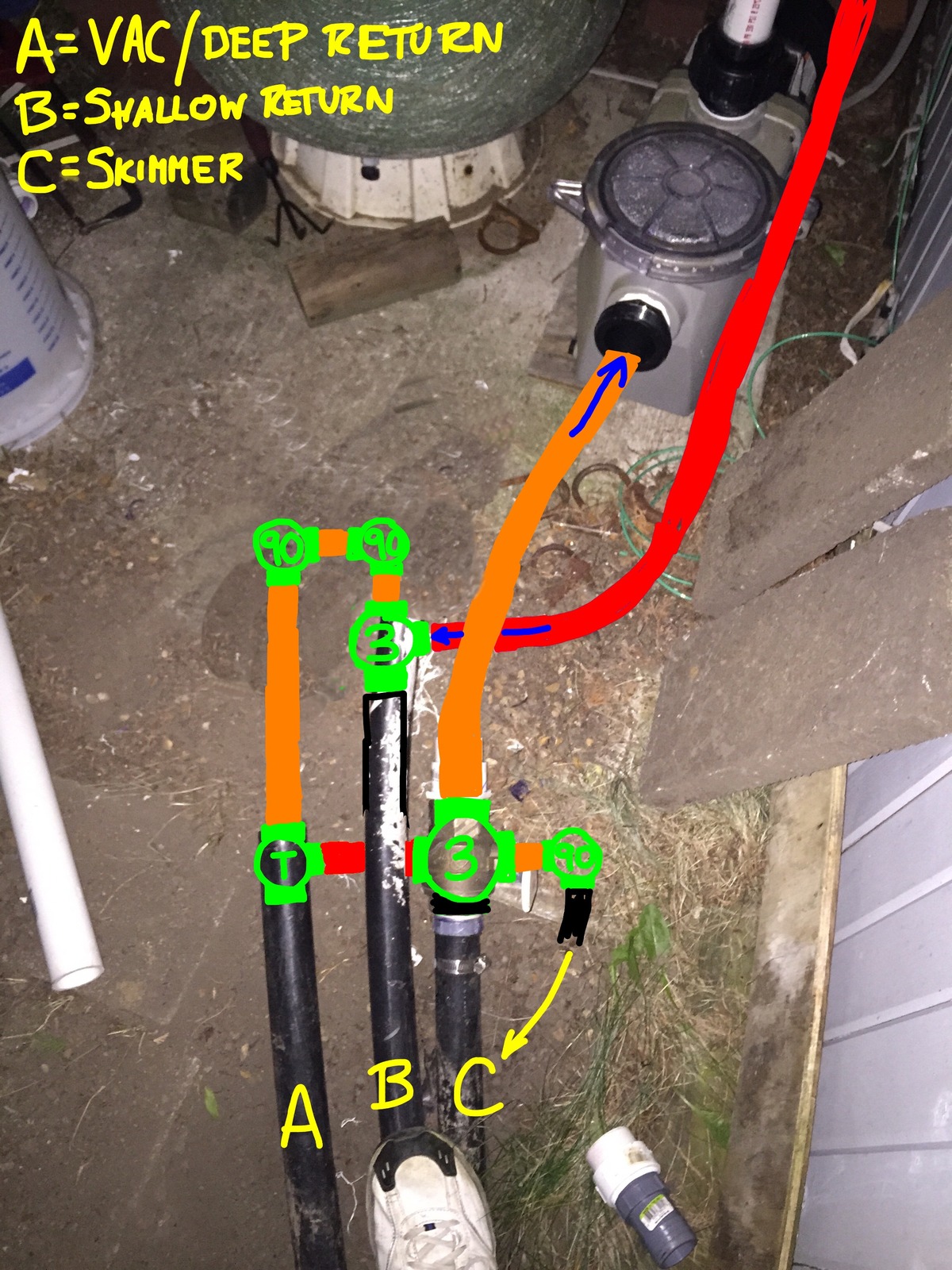

I hope that the multiple topics on similar but slightly different topics isn't a problem... but I'm wondering if the diagram I've constructed will work. The lines are labelled the same in each photo:

A = deep end line (currently a vac line)

B = shallow end return line

C = skimmer line

The above is the original configuration, with two shutoff valves for the skimmer and vac line. Here, there is just a single return.

This is is me getting choppy choppy before I had a proper plan laid out. Although not labelled here, the lines are A, B, & C from left to right. I think it'd be easier to tie them together this way.

Here is what I want to do: I'd love to be able to ditch the shutoff valves and configure the 3 way valves such that I can have both A&B or just B as return lines, while also being able to change the suction side to have A&C or just C as suction lines (obviously I wouldn't want both the suction and return valves open to line A at the same time...)

Is this possible to configure the 3-ways in this fashion, and would I need to get a special valve that would allow me to re-configure how the ports operate?

I could have tried to do this with three shutoff valves, but doing so would have gotten real messy and might have cramped what little space I have available

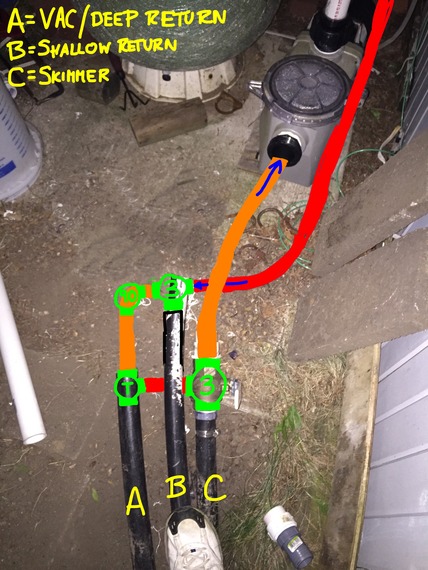

A = deep end line (currently a vac line)

B = shallow end return line

C = skimmer line

The above is the original configuration, with two shutoff valves for the skimmer and vac line. Here, there is just a single return.

This is is me getting choppy choppy before I had a proper plan laid out. Although not labelled here, the lines are A, B, & C from left to right. I think it'd be easier to tie them together this way.

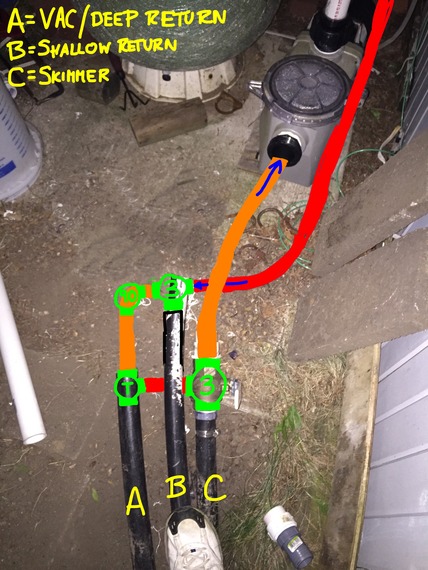

Here is what I want to do: I'd love to be able to ditch the shutoff valves and configure the 3 way valves such that I can have both A&B or just B as return lines, while also being able to change the suction side to have A&C or just C as suction lines (obviously I wouldn't want both the suction and return valves open to line A at the same time...)

Is this possible to configure the 3-ways in this fashion, and would I need to get a special valve that would allow me to re-configure how the ports operate?

I could have tried to do this with three shutoff valves, but doing so would have gotten real messy and might have cramped what little space I have available