It appears that my designer over engineered or made a mistake when designing my water features pump wise. Here’s my current setup:

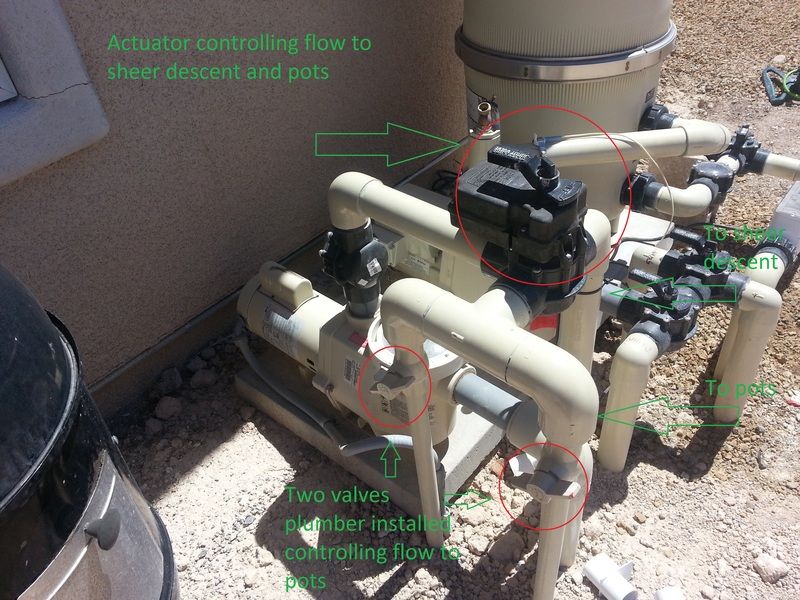

Here’s my plumbing; water leaves pump and flows to a T with an value and actuator. On one side of the T the water flows to my sheer descent, on the other side it flows to another T that splits the water to the two pots. After the pots T there are two small manual valves to control the amount of water going to each pot to insure they fill at the same rate and to restrict the amount of water flowing to them as if they weren’t there the pots would overflow from the pressure.

The valve/actuator is in place so that we can run the turn off the sheer descent and run only the pots as waterfall can be quite loud or if we need to use the bench below the waterfall.

Here’s the issue, when we close the valve turning off water to the sheer descent, the water pressure increases to the pots overflowing the pots. So I have to run over and adjust the small valves to slow the water flow to the pots. Then, when we want turn the sheer descent on I have to run back over and adjust the pot valves. PITA! Especially when I purchased the automation system and have everything else configured to run from my phone, iPad or computer, I don’t want to be running back and forth adjusting the valves.

So I spoke to Pentair today and they suggested three options:

I hate the idea of losing money on my current pump; paying to have it removed, buying a new pump and paying to have it installed, BUT my goal was to have this automated and using my current pump the only way to do this is to always run all three features. I hope this was clear.

So, if this was your pool what would you do?

One Whisperflo 3 hp single speed pump

Two pot scuppers

One 48” sheer descent

Two pot scuppers

One 48” sheer descent

Here’s my plumbing; water leaves pump and flows to a T with an value and actuator. On one side of the T the water flows to my sheer descent, on the other side it flows to another T that splits the water to the two pots. After the pots T there are two small manual valves to control the amount of water going to each pot to insure they fill at the same rate and to restrict the amount of water flowing to them as if they weren’t there the pots would overflow from the pressure.

The valve/actuator is in place so that we can run the turn off the sheer descent and run only the pots as waterfall can be quite loud or if we need to use the bench below the waterfall.

Here’s the issue, when we close the valve turning off water to the sheer descent, the water pressure increases to the pots overflowing the pots. So I have to run over and adjust the small valves to slow the water flow to the pots. Then, when we want turn the sheer descent on I have to run back over and adjust the pot valves. PITA! Especially when I purchased the automation system and have everything else configured to run from my phone, iPad or computer, I don’t want to be running back and forth adjusting the valves.

So I spoke to Pentair today and they suggested three options:

1) Install a bypass valve so that it will divert extra pressure back to the pool through my returns. However, there’s no guarantee that I won’t be manually adjusting the pot valves when sheer descent is on. Also, I suppose I have to manually adjust the bypass valve completely defeating the purpose of automating.

2) I sell my 3 hp Whisperflo and purchase a Variable flow pump which I could program with two circuits with different gpm flow rates so when I have all three features on 80 gpm flow through, when I only have the pots on 40 gpm flow through (numbers are pure guess meant more for illustration). This would be automated through my app/computer. Seems to me most expensive route as these pumps aren’t cheap.

3) I sell my 3 hp Whisperflo and purchase a Variable speed pump which I could program with two circuits with different rpm rates so when I have all three features on it runs at 2400 rpm, when I only have the pots on it runs at 1300 rpm (numbers are pure guess meant more for illustration). This would be automated through my app/computer. Less expensive than option two and seems to work.

2) I sell my 3 hp Whisperflo and purchase a Variable flow pump which I could program with two circuits with different gpm flow rates so when I have all three features on 80 gpm flow through, when I only have the pots on 40 gpm flow through (numbers are pure guess meant more for illustration). This would be automated through my app/computer. Seems to me most expensive route as these pumps aren’t cheap.

3) I sell my 3 hp Whisperflo and purchase a Variable speed pump which I could program with two circuits with different rpm rates so when I have all three features on it runs at 2400 rpm, when I only have the pots on it runs at 1300 rpm (numbers are pure guess meant more for illustration). This would be automated through my app/computer. Less expensive than option two and seems to work.

I hate the idea of losing money on my current pump; paying to have it removed, buying a new pump and paying to have it installed, BUT my goal was to have this automated and using my current pump the only way to do this is to always run all three features. I hope this was clear.

So, if this was your pool what would you do?