Well, my parents old 2HP Hayward superpump finally bit the dust a week ago. Of course it happened just as I was in the process of shocking the pool back from its dark green swamp state. This lead me to an impulse purchase of a Pentair Superflo 1.5HP pump at my local pool supply place. The sales guy there thought I would be OK with a 1HP pump, but when I told him I had an Autopilot SWCG he recommended I buy the 1.5HP instead. He thought the 1HP may not be able to provide the flow rate the Autopilot might need. I haven't installed the pump yet so I could still go back and swap out for the 1HP unit if needed.

Which leads me to where I need some advice. My parents 23,000 gallon pool is an old in ground with 1.5 inch plumbing through out. It has separate bottom drain and skimmer lines on the suction side and two returns; one at the deep end and another line at the shallow end steps that splits off to two eyeball adjustable returns.

At the pad there is a Triton TR-60 Sand filter and of course the Autopilot SWG manifold, which is two inch pipe. All other pipe at the pad is 1.5 inch. The Autopilot has a by-pass type manifold which has a check valve that allows excess flow, over 20 gpm, to by-pass the cell. This is why I'm thinking I could probably get away with the smaller pump after all.

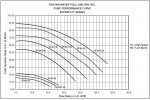

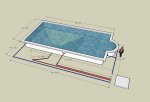

I've attached a picture I drew up in Sketchup that illustrates the pool and line runs. Blue colored pipes are return, and of course red are the suction side. I've also attached a pic of the pad and the pump curves for the Pentair Super Flo line of pumps. Yes, the pad plumbing needs some serious work, and is one area I'm thinking I could use 2 inch pipes to make the system more efficiet.

So I could use some advice on how to approach this pump replacement. I've read through the Hydraulics 101 sticky and best I can come up with is that I've got in the area of 35+ feet of head if I go by the sand filters pressure reading of 12psi with the old 2HP Hayward pump. But if I do a rough estimate based on pipe run and bends it shoots up to 60+! I know it's not much to go on but what do you guys think, could I get away with the 1HP pump? It is only a $70 price difference between the two, but I'm sure my parents would appreciate the lower utility bills if it would work.

Thanks,

Paul

Which leads me to where I need some advice. My parents 23,000 gallon pool is an old in ground with 1.5 inch plumbing through out. It has separate bottom drain and skimmer lines on the suction side and two returns; one at the deep end and another line at the shallow end steps that splits off to two eyeball adjustable returns.

At the pad there is a Triton TR-60 Sand filter and of course the Autopilot SWG manifold, which is two inch pipe. All other pipe at the pad is 1.5 inch. The Autopilot has a by-pass type manifold which has a check valve that allows excess flow, over 20 gpm, to by-pass the cell. This is why I'm thinking I could probably get away with the smaller pump after all.

I've attached a picture I drew up in Sketchup that illustrates the pool and line runs. Blue colored pipes are return, and of course red are the suction side. I've also attached a pic of the pad and the pump curves for the Pentair Super Flo line of pumps. Yes, the pad plumbing needs some serious work, and is one area I'm thinking I could use 2 inch pipes to make the system more efficiet.

So I could use some advice on how to approach this pump replacement. I've read through the Hydraulics 101 sticky and best I can come up with is that I've got in the area of 35+ feet of head if I go by the sand filters pressure reading of 12psi with the old 2HP Hayward pump. But if I do a rough estimate based on pipe run and bends it shoots up to 60+! I know it's not much to go on but what do you guys think, could I get away with the 1HP pump? It is only a $70 price difference between the two, but I'm sure my parents would appreciate the lower utility bills if it would work.

Thanks,

Paul