I've heard that the entre water of the pool needs to go through the filter once per day. Typically, that means the pump has to run about 8 hours.

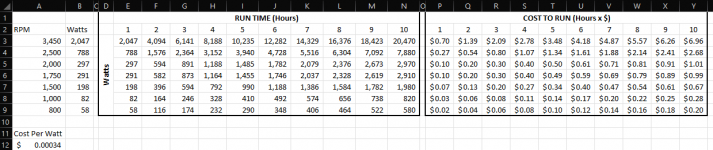

I've been looking at the equipment that was installed here to see if I can save some money. It turns out I have a Jandy VSSHP270DV2A pump which is in Jandy's "Commercial" pump section. To my surprise, this is quite a powerful unit. I looked at the manual and found this:

I estimate my pool size to be 10K gallons or so and the pump always runs at 3450 RPM, according to iAcqualink.

Without knowing the Total Dynamic Head and just going with 80 GPM (middle of the chart), that means that this pump moves 4,800 gallons of water per hour. Estimating even more conservatively and using 60 GPM, that means that it can move 3,600 gallons of water per hour.

Considering that I have a 10K gallon pool, heck, let's say 12K gallons to be safe, would it be safe to assume that I just need to run this pump for 3-4 hours a day? I've been experimenting all winter and running it 4.5 hours a day (the installer left it at 8 hours) and testing frequently and haven't seen anything happen to the water. It has been crystal clear for months now.

Is my math here right or am I missing something? I wonder if I could reduce run time even more to like 3 hours, but would like to get some opinions. I wonder if the math really is that straight forward. I could also leave it running longer at a lower RPM, but I'm not sure what the preferred option is.

Also, assuming I can run it for less time, I will need to crank up the SWG to compensate for the reduced running time, right? The installer left it at 80% and when I finally started testing myself I discovered my chlorine was at an insane 14 ppm. I've adjusted since then, always based on testing, and I've managed to keep it at 10-30%, most of the time staying between 15-20%.

For reference, here's the manual of my pump: https://www.jandy.com/-/media/zodia...5700.pdf?rev=a135e740888444e680a0d3d0a77ce28e

I've been looking at the equipment that was installed here to see if I can save some money. It turns out I have a Jandy VSSHP270DV2A pump which is in Jandy's "Commercial" pump section. To my surprise, this is quite a powerful unit. I looked at the manual and found this:

I estimate my pool size to be 10K gallons or so and the pump always runs at 3450 RPM, according to iAcqualink.

Without knowing the Total Dynamic Head and just going with 80 GPM (middle of the chart), that means that this pump moves 4,800 gallons of water per hour. Estimating even more conservatively and using 60 GPM, that means that it can move 3,600 gallons of water per hour.

Considering that I have a 10K gallon pool, heck, let's say 12K gallons to be safe, would it be safe to assume that I just need to run this pump for 3-4 hours a day? I've been experimenting all winter and running it 4.5 hours a day (the installer left it at 8 hours) and testing frequently and haven't seen anything happen to the water. It has been crystal clear for months now.

Is my math here right or am I missing something? I wonder if I could reduce run time even more to like 3 hours, but would like to get some opinions. I wonder if the math really is that straight forward. I could also leave it running longer at a lower RPM, but I'm not sure what the preferred option is.

Also, assuming I can run it for less time, I will need to crank up the SWG to compensate for the reduced running time, right? The installer left it at 80% and when I finally started testing myself I discovered my chlorine was at an insane 14 ppm. I've adjusted since then, always based on testing, and I've managed to keep it at 10-30%, most of the time staying between 15-20%.

For reference, here's the manual of my pump: https://www.jandy.com/-/media/zodia...5700.pdf?rev=a135e740888444e680a0d3d0a77ce28e