- Jun 8, 2020

- 590

- Pool Size

- 14060

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

I've ordered an AquaCal SQ150VS heat pump, and will be doing a self install when it arrives. So in preparation of that, I'm taking a hard look at the electrical layout of my house and the pool equipment.

A coupe of years ago, when I added an EcoSmart 27kW tankless hot water heater during a master bath remodel, I called my local electric company and had them come out and advise me on if I needed a service upgrade to handle the tankless heater. They told me I did not, and should be fine adding it in. This required adding three 40Amp double throw breakers into my main panel, which is fed by a 200A service.

When the pool was installed last year, I repurposed a 50A breaker spot which was feeding a welder circuit in my garage (which I've only used once in 14 years) to make room for the 50A breaker for the EasyTouch load center.

So now I'm trying to determine if I can add the pool heat pump to the mix, or if I've finally gotten to the point where I need a service upgrade; which honestly, I think I should have done when I added the tankless.

If I do need a service upgrade ... what are my options are for doing so (complete main panel replacement for a 400A panel, or ... adding a 2nd 200A panel in parallel, or ... adding a 100A single cut-off breaker box in parallel to feed the EasyTouch sub-panel, or ... something I'm not considering?). I realize the answer to this is impacted by local code as well.

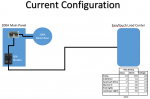

Here is what my main panel looks like today:

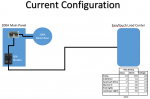

And below is how the EasyTouch is currently tied in, along with the loads running off the ET's panel

Note: The existing wiring between the main panel and the ET panel consists of four THHN 8AWG wires in conduit (not romex). My understanding is this type of install allows the 75*c table to be used for determining load capabilities; so I'm currently ok with 8AWG and a 50A breaker. But any increase in breaker size would require upgrading the 8AWG wires to the ET panel.

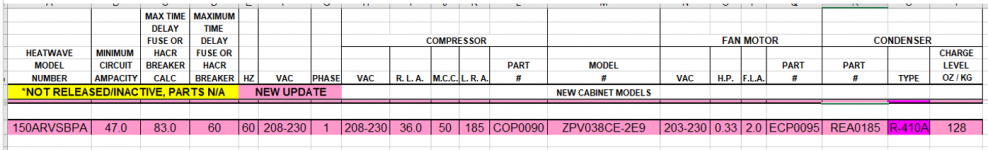

The heat pump's RLA (Rated Load Amps) spec is 36A, with minimum circuit ampacity of 47A and max breaker size of 60A. So I'm using 36A for load calc, and 50A for the circuit breaker.

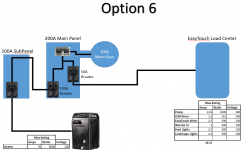

I know the EasyTouch is a 150A capable sub-panel, so I wonder if I can upgrade my service to 320/400, keep my existing 200A panel, and add a 100A circuit breaker enclosure in parallel to feed the EasyTouch. I think this would be the most cost effective option, if it's an acceptable solution per code and the local electric company.

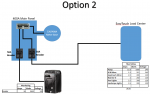

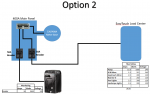

Option 2 is the most expensive, and would be upgrading to 320/400A service and replacing the 200A panel with a 400A main panel. Then run the heater from a dedicated CB in the main panel.

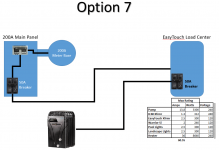

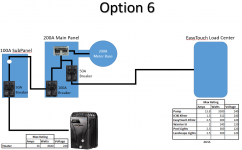

And I'm sure there's other options too, like upgrading the service to 320/400, upgrading the main panel to 400, and then installing a 100A breaker to feed the EasyTouch load center as a sub-panel, and adding a dedicated 50A breaker in the ET for the heater:

Or maybe I should just install a 2nd 200A panel, since I'm out of room?

Another option would be to go with the 2nd 200A panel in parallel, and run the ET from a 50A breaker, use a 2nd 50A breaker for the new heat pump, and then I could also move the tankless water heater breakers over as well to this new panel. This would probably give me the most flexibility, but again, would be a costly option.

The main panel and the EasyTouch panel are fairly close to each other, on the same exterior wall of the house. So any of these options should be fairly easy to implement, but I think replacing my main panel will be costly since every circuit will need to be rewired from the old panel to the new.

As you can probably tell, I may be over thinking this to some extent. I plan to call the electric company out here again, to consult with me on options ... but would like to get some input in the meantime.

Any advice here would be greatly appreciated!

A coupe of years ago, when I added an EcoSmart 27kW tankless hot water heater during a master bath remodel, I called my local electric company and had them come out and advise me on if I needed a service upgrade to handle the tankless heater. They told me I did not, and should be fine adding it in. This required adding three 40Amp double throw breakers into my main panel, which is fed by a 200A service.

When the pool was installed last year, I repurposed a 50A breaker spot which was feeding a welder circuit in my garage (which I've only used once in 14 years) to make room for the 50A breaker for the EasyTouch load center.

So now I'm trying to determine if I can add the pool heat pump to the mix, or if I've finally gotten to the point where I need a service upgrade; which honestly, I think I should have done when I added the tankless.

If I do need a service upgrade ... what are my options are for doing so (complete main panel replacement for a 400A panel, or ... adding a 2nd 200A panel in parallel, or ... adding a 100A single cut-off breaker box in parallel to feed the EasyTouch sub-panel, or ... something I'm not considering?). I realize the answer to this is impacted by local code as well.

Here is what my main panel looks like today:

And below is how the EasyTouch is currently tied in, along with the loads running off the ET's panel

Note: The existing wiring between the main panel and the ET panel consists of four THHN 8AWG wires in conduit (not romex). My understanding is this type of install allows the 75*c table to be used for determining load capabilities; so I'm currently ok with 8AWG and a 50A breaker. But any increase in breaker size would require upgrading the 8AWG wires to the ET panel.

The heat pump's RLA (Rated Load Amps) spec is 36A, with minimum circuit ampacity of 47A and max breaker size of 60A. So I'm using 36A for load calc, and 50A for the circuit breaker.

I know the EasyTouch is a 150A capable sub-panel, so I wonder if I can upgrade my service to 320/400, keep my existing 200A panel, and add a 100A circuit breaker enclosure in parallel to feed the EasyTouch. I think this would be the most cost effective option, if it's an acceptable solution per code and the local electric company.

Option 2 is the most expensive, and would be upgrading to 320/400A service and replacing the 200A panel with a 400A main panel. Then run the heater from a dedicated CB in the main panel.

And I'm sure there's other options too, like upgrading the service to 320/400, upgrading the main panel to 400, and then installing a 100A breaker to feed the EasyTouch load center as a sub-panel, and adding a dedicated 50A breaker in the ET for the heater:

Or maybe I should just install a 2nd 200A panel, since I'm out of room?

Another option would be to go with the 2nd 200A panel in parallel, and run the ET from a 50A breaker, use a 2nd 50A breaker for the new heat pump, and then I could also move the tankless water heater breakers over as well to this new panel. This would probably give me the most flexibility, but again, would be a costly option.

The main panel and the EasyTouch panel are fairly close to each other, on the same exterior wall of the house. So any of these options should be fairly easy to implement, but I think replacing my main panel will be costly since every circuit will need to be rewired from the old panel to the new.

As you can probably tell, I may be over thinking this to some extent. I plan to call the electric company out here again, to consult with me on options ... but would like to get some input in the meantime.

Any advice here would be greatly appreciated!

Last edited: