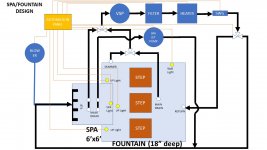

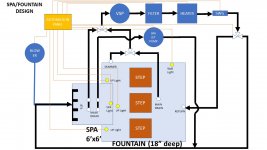

Planning a SPA/Fountain addition to second home in Florida. Spa is 6'x6' and spills into a shallow (18") fountain/pond that has a couple of built in steps to cross over. Pool builder is a Pentair guy. Please help me with the following:

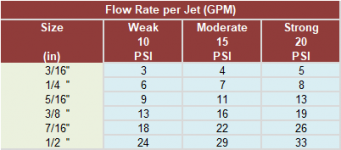

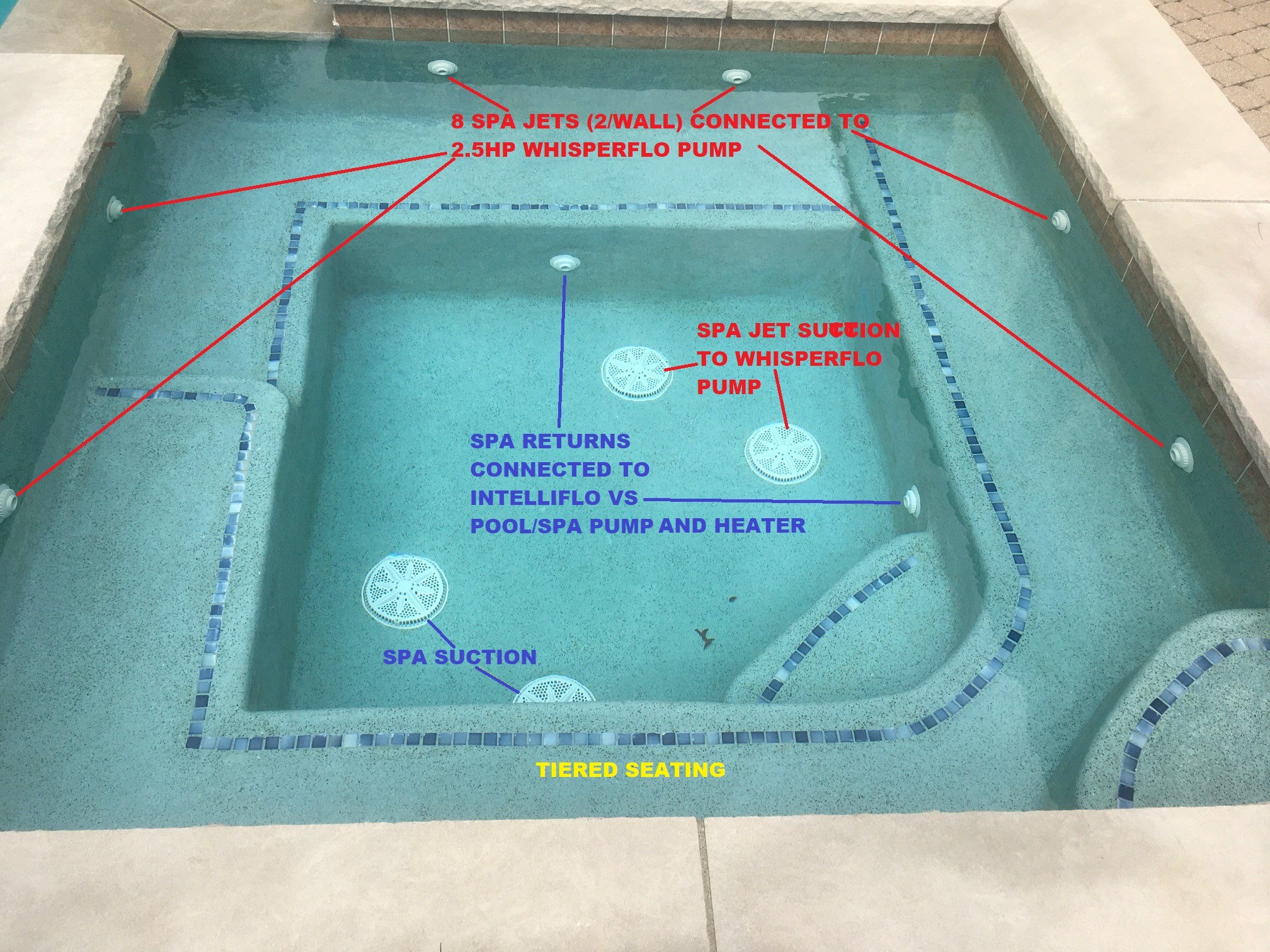

1) Is the separate Spa Jet Pump necessary or would a 3HP VSP (even with losses thru Filter, Heater, and SWG) provide enough jet pressure at the spa?

2) How many jets do you recommend for a 6x6 SPA? Is one Blower sufficient? If so, what HP?

3) Automation - Easytouch with Screen Logic or Intellicenter?

4) Maintenance - I'd like to avoid hiring a pool guy during summer months when house is unoccupied. Plan to have an Autofill and overflow valve to take care of water levels. SWG should take care of chlorine levels reliably. Can the rest of the chemistry be automated with IntelliChem?

5) Any recommended Pentair model numbers for equipment would be appreciated!

1) Is the separate Spa Jet Pump necessary or would a 3HP VSP (even with losses thru Filter, Heater, and SWG) provide enough jet pressure at the spa?

2) How many jets do you recommend for a 6x6 SPA? Is one Blower sufficient? If so, what HP?

3) Automation - Easytouch with Screen Logic or Intellicenter?

4) Maintenance - I'd like to avoid hiring a pool guy during summer months when house is unoccupied. Plan to have an Autofill and overflow valve to take care of water levels. SWG should take care of chlorine levels reliably. Can the rest of the chemistry be automated with IntelliChem?

5) Any recommended Pentair model numbers for equipment would be appreciated!