- Jun 8, 2020

- 18

- Pool Size

- 13000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-9)

Hello TFP! I've been a lurker here for over a year since I bought a house that had a pool and it has been an immense help in getting my water chemistry under control(CYA was off the charts on the first test!). Now that I have a full summer under my belt with good results I've been looking at how to optimize my SWCG and pool/spa for the winter. Details on my setup:

- 12,500 inground gunnite pool/spa

- Spa plumbed for spill-over and solo flow

- Hayward Ecommand4 panel

- Aquarite AQR9 SWCG

- Hayward heater

- Booster pump

- Blower for spa

The issue I'm trying to resolve is that the SWCG is wired in with the filter and the only control on generation is by adjusting the dial on the panel. This is fine during the summer but as things cool down my kids tend to use our spa as the "pool" for the winter which leads to it being on quite often at a higher than needed generation rate. I took a look at the AQR9 manual and it clearly shows how to wire the SWCG to the Ecommand4 which would allow for the pool and spa to operate at different generation percentages. I went out and bought the correct 4 conductor cable and when I took the front off the Ecommand4 was a little concerned with what I found.

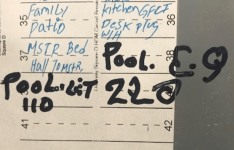

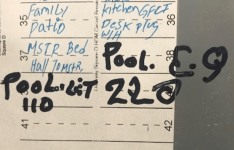

Starting with the basics, below are pictures of my main panel in my house. Breaker 39 is the 110v for the pool and 38/40 are the 220v for the pool. The first thing that jumped out at me was the 110 is not a gfci breaker, but when I followed it out to the pool pad I noticed that the outlet below the panel does have a gfci receptacle.

Now is where it really got interesting, the Ecommand4 subpanel does not have any breakers installed and the line voltage coming in and the loads going out are all wired directly to the controlled relays. Looking a little further at the Filter Pump load out wiring shows that one set of the wiring actually goes out to the Filter Pump but the other set of load outs goes to a wire nut that is also powering the SWCG and the Heater.

So this leaves me with a few questions:

1. First for sake of safety is the 110v ok with it being wired through the gfci receptacle below the panel and not on a gfci breaker at the main house panel or a gfci breaker inside the Ecommand 4 subpanel?

2. How common is this style of wiring where they completely bypassed the local subpanel and everything is wired directly into the relays? If nothing else it would seem to be more convenient to have local breakers for each piece of equipment to identify issues.

3. Is there an easy way to implement my intended control scheme with the Ecommand4 handling the SWCG generation percentage based on pool/spa mode? In the manual it shows that the SWCG must be wired to the incoming 220v so that it is "always on" and then the automation sends the run signal and percentage values. In order to achieve this setup it would seem that I need switch the setup to have incoming voltage landed at the subpanel and then add 2 breakers, 1 to supply power to the filter pump relay and the 2nd to supply power to the SWCG.

Thanks in advance for any advice in this area and sorry for the lengthy and details post.

Thanks,

Cory

- 12,500 inground gunnite pool/spa

- Spa plumbed for spill-over and solo flow

- Hayward Ecommand4 panel

- Aquarite AQR9 SWCG

- Hayward heater

- Booster pump

- Blower for spa

The issue I'm trying to resolve is that the SWCG is wired in with the filter and the only control on generation is by adjusting the dial on the panel. This is fine during the summer but as things cool down my kids tend to use our spa as the "pool" for the winter which leads to it being on quite often at a higher than needed generation rate. I took a look at the AQR9 manual and it clearly shows how to wire the SWCG to the Ecommand4 which would allow for the pool and spa to operate at different generation percentages. I went out and bought the correct 4 conductor cable and when I took the front off the Ecommand4 was a little concerned with what I found.

Starting with the basics, below are pictures of my main panel in my house. Breaker 39 is the 110v for the pool and 38/40 are the 220v for the pool. The first thing that jumped out at me was the 110 is not a gfci breaker, but when I followed it out to the pool pad I noticed that the outlet below the panel does have a gfci receptacle.

Now is where it really got interesting, the Ecommand4 subpanel does not have any breakers installed and the line voltage coming in and the loads going out are all wired directly to the controlled relays. Looking a little further at the Filter Pump load out wiring shows that one set of the wiring actually goes out to the Filter Pump but the other set of load outs goes to a wire nut that is also powering the SWCG and the Heater.

So this leaves me with a few questions:

1. First for sake of safety is the 110v ok with it being wired through the gfci receptacle below the panel and not on a gfci breaker at the main house panel or a gfci breaker inside the Ecommand 4 subpanel?

2. How common is this style of wiring where they completely bypassed the local subpanel and everything is wired directly into the relays? If nothing else it would seem to be more convenient to have local breakers for each piece of equipment to identify issues.

3. Is there an easy way to implement my intended control scheme with the Ecommand4 handling the SWCG generation percentage based on pool/spa mode? In the manual it shows that the SWCG must be wired to the incoming 220v so that it is "always on" and then the automation sends the run signal and percentage values. In order to achieve this setup it would seem that I need switch the setup to have incoming voltage landed at the subpanel and then add 2 breakers, 1 to supply power to the filter pump relay and the 2nd to supply power to the SWCG.

Thanks in advance for any advice in this area and sorry for the lengthy and details post.

Thanks,

Cory