Hello and good day!!

I have a Pentair VS that is fairly new (6 mos) and is not starting.

The panel control shows power and the pump itself shows power. When I mean power, when I hit the panel control button to turn it on, the indicator light is red and active. Second, the panel on the pump has power, the LCD works fine (proper display) and the stop/start is on (using the panel).

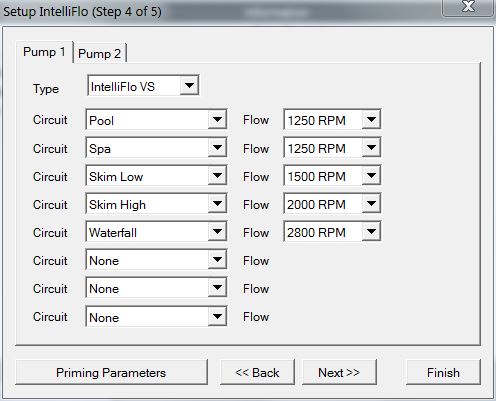

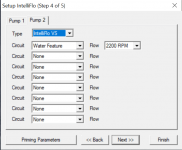

None of the breakers are popped and our second VS pump works fine. This pump is strictly for our water features and is clear (not a skimmer or filter pump).

What troubleshooting steps would you recommend?

Thanks in advance.

I have a Pentair VS that is fairly new (6 mos) and is not starting.

The panel control shows power and the pump itself shows power. When I mean power, when I hit the panel control button to turn it on, the indicator light is red and active. Second, the panel on the pump has power, the LCD works fine (proper display) and the stop/start is on (using the panel).

None of the breakers are popped and our second VS pump works fine. This pump is strictly for our water features and is clear (not a skimmer or filter pump).

What troubleshooting steps would you recommend?

Thanks in advance.