Hi all, I have received much good info here and as a newly Registered Member would like to thank you all for helping others, which helped me.

I now have a problem that I think I know the answer to, but lack the experience, so where better to ask for help.

I replaced a very old 2 HP Pump/Motor last Oct. with a Pentair Superflo 1 HP Pump/Motor. Installed and wired easily, except it was longer overall

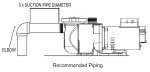

and caused me to ignore the 5 X Pipe Diameter [2"] = 10" length of pipe recommended between the 90 degree fitting and the Pump Inlet [see pic].

The Suction created and water pressure coming in thru the returns was waayyyyy higher than any previous pump [my first clue]. The Kreepy Krauly went so fast I had to use an in-line hose fitting to bleed off suction [second clue]. It did however work well. The pump itself is quiet, but sound of the water moving thru the pipes is louder than before [third clue].

Now, the reason for my post is that my last Electric bill was easily $45 higher, and I have not even used the Air Conditioning yet. Nothing else has changed use-wise [I live Alone and

know my usage].

I looked at bills going back to Oct, and all were 20 to 30% higher. The Picture shows the present install/mistake.

Is this the reason for the higher bills and the louder operating noise and should I re-Plumb for this or other reasons?

Thank - Tony

I now have a problem that I think I know the answer to, but lack the experience, so where better to ask for help.

I replaced a very old 2 HP Pump/Motor last Oct. with a Pentair Superflo 1 HP Pump/Motor. Installed and wired easily, except it was longer overall

and caused me to ignore the 5 X Pipe Diameter [2"] = 10" length of pipe recommended between the 90 degree fitting and the Pump Inlet [see pic].

The Suction created and water pressure coming in thru the returns was waayyyyy higher than any previous pump [my first clue]. The Kreepy Krauly went so fast I had to use an in-line hose fitting to bleed off suction [second clue]. It did however work well. The pump itself is quiet, but sound of the water moving thru the pipes is louder than before [third clue].

Now, the reason for my post is that my last Electric bill was easily $45 higher, and I have not even used the Air Conditioning yet. Nothing else has changed use-wise [I live Alone and

know my usage].

I looked at bills going back to Oct, and all were 20 to 30% higher. The Picture shows the present install/mistake.

Is this the reason for the higher bills and the louder operating noise and should I re-Plumb for this or other reasons?

Thank - Tony

Welcome to TFP!!!

Welcome to TFP!!!