DIY IG LINER POOLS -- part 5 -- plumbing and lighting

- Thread starter waste

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Time has finally allowed

I CAN'T believe this is my first partial rain day in ~ a month :grrrr:

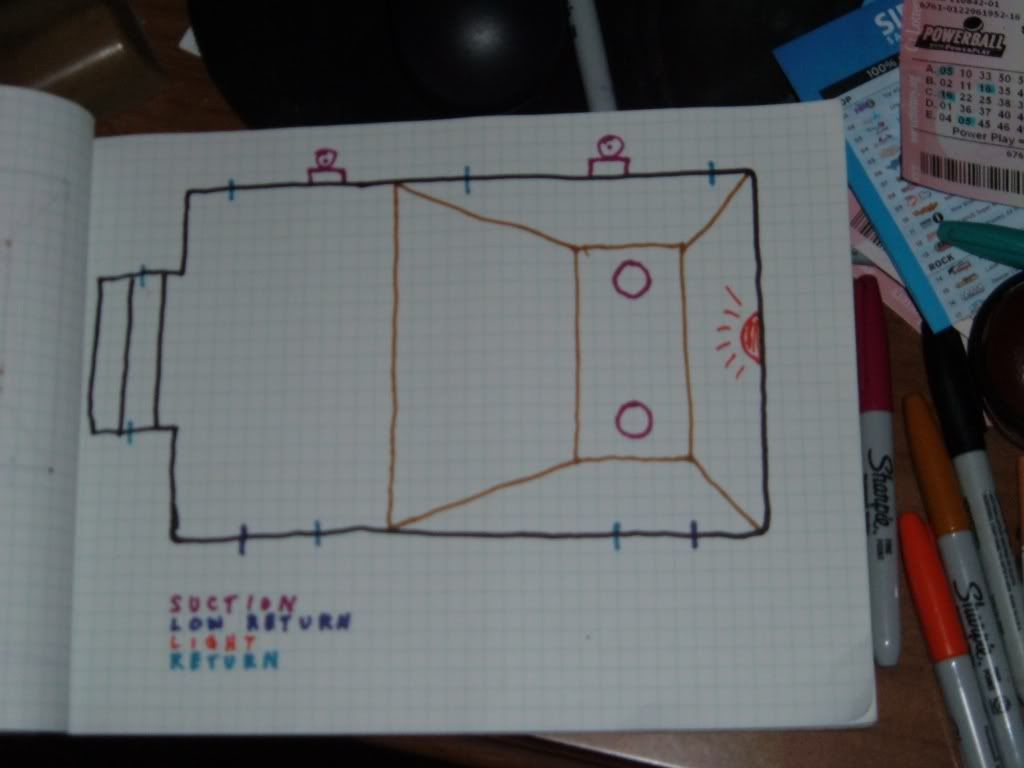

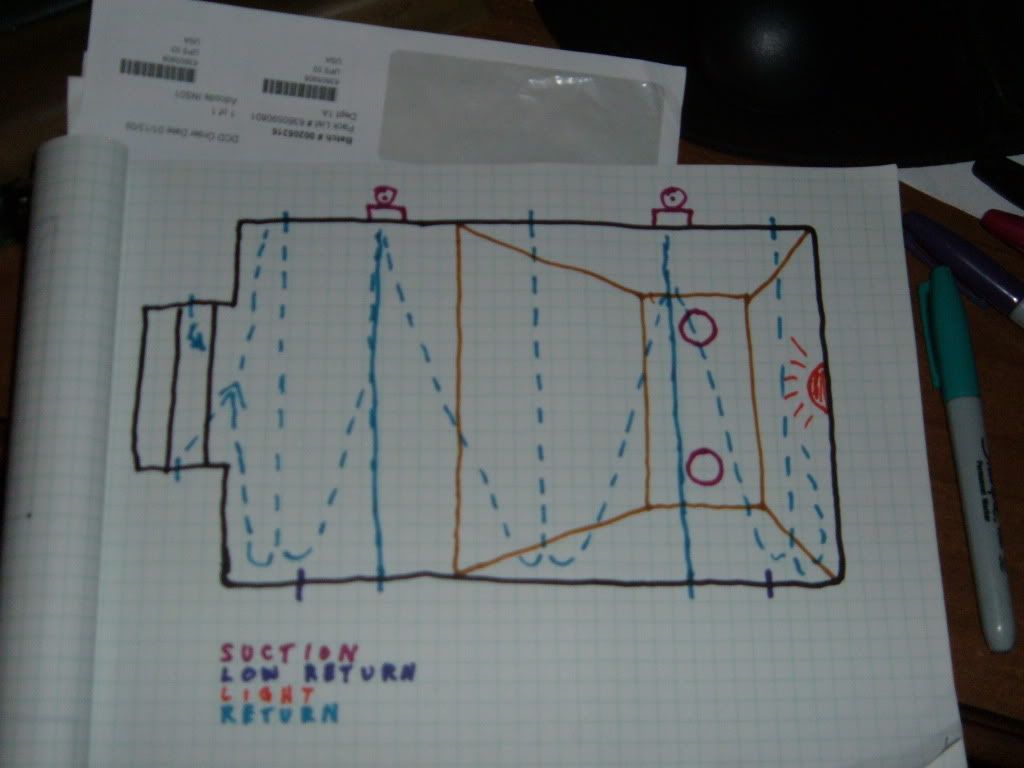

Here (fingers crossed) is a pic of how we do pools

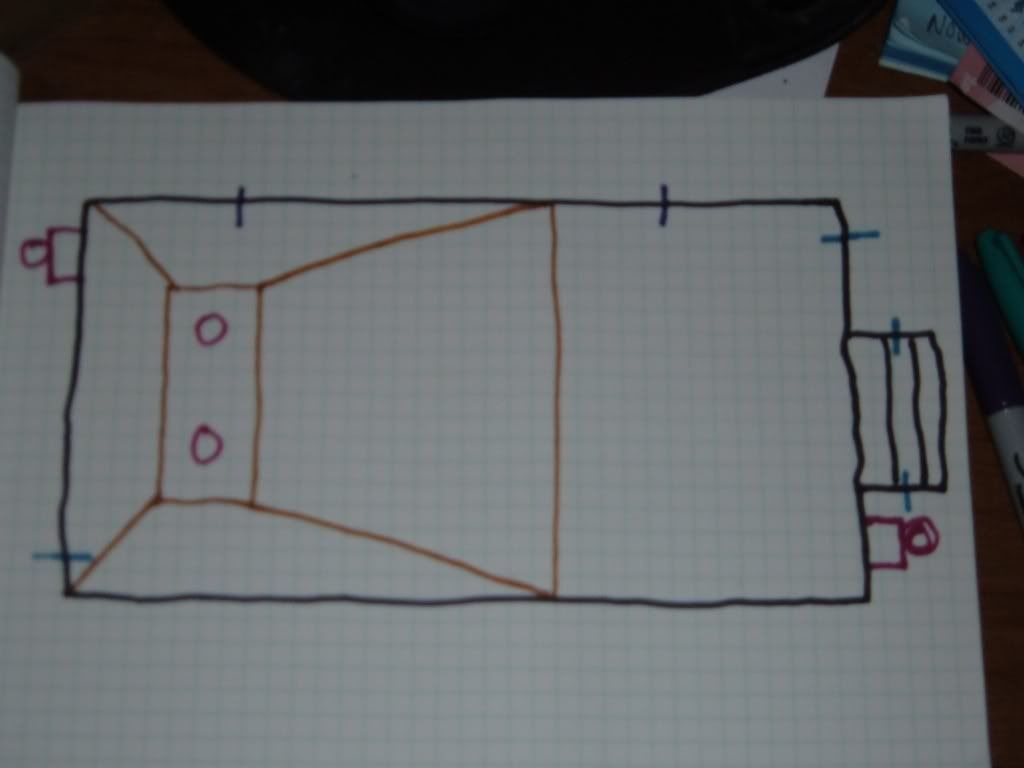

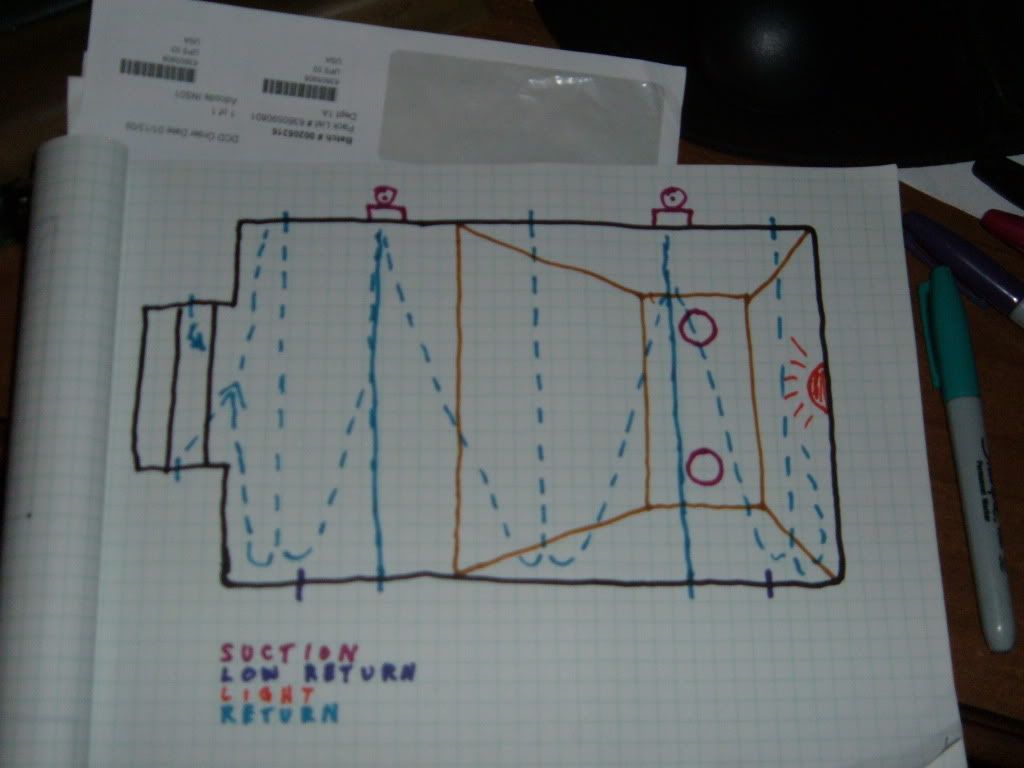

And Mas' suggestion (I got the low returns wrong )

)

Holy ****!!!! I actually posted a couple of pics while the wife's at work :super:

Sorry it's taken me so long! Hope you enjoy the pics (now that I know how to do this, I can give more 8) )

I CAN'T believe this is my first partial rain day in ~ a month :grrrr:

Here (fingers crossed) is a pic of how we do pools

And Mas' suggestion (I got the low returns wrong

Holy ****!!!! I actually posted a couple of pics while the wife's at work :super:

Sorry it's taken me so long! Hope you enjoy the pics (now that I know how to do this, I can give more 8) )

YAY! You posted pics!  I was gonna PM you a few days ago but figured you wouldn't forget about lil ole me! :-D

I was gonna PM you a few days ago but figured you wouldn't forget about lil ole me! :-D

Love the diagrams!

The first pic...

I see you have 3 returns on the skimmer side. Are all those to be pointed down the wall towards the skimmers except for the step returns?

Each skimmer is on it's own dedicated line right? And the low returns are on the same wall opposite the skimmers...

You did good waste! Don't you just love the DIY drawings?!

Love the diagrams!

The first pic...

I see you have 3 returns on the skimmer side. Are all those to be pointed down the wall towards the skimmers except for the step returns?

Each skimmer is on it's own dedicated line right? And the low returns are on the same wall opposite the skimmers...

You did good waste! Don't you just love the DIY drawings?!

Hey Casey

Again, I'm sorry for the delay (It's been 4 crazy overtime weeks - the only week I didn't top 60 hours was Memorial Day week, where we only got 56 hours on a 'short' 5 day week

(It's been 4 crazy overtime weeks - the only week I didn't top 60 hours was Memorial Day week, where we only got 56 hours on a 'short' 5 day week  )

)

All regular returns are pointed ever-so-slightly up but straight ahead

I've tried to modify the original pic with the blue marker

Again, I'm sorry for the delay

All regular returns are pointed ever-so-slightly up but straight ahead

I've tried to modify the original pic with the blue marker

I get it! At first, I was like WTH is going on but as I studied the pattern of water flow, it looks pretty cool.

Now the hard part... I have to decide which one I want to go with. The good part is, my dad is due to come down tomorrow morning and I'm gonna have him take a look at both drawings and see what he thinks. 8)

Thanks for your precious time waste!

Now the hard part... I have to decide which one I want to go with. The good part is, my dad is due to come down tomorrow morning and I'm gonna have him take a look at both drawings and see what he thinks. 8)

Thanks for your precious time waste!

Casey, don't go with the way we do things just because I showed you how it flows. There is nothing wrong with the circulation pattern Mas set up - it's just not as many returns to force the stuff on the surface into the skimmers and is a lot less plumbing

We've still got a little time to 'hammer out the details' on this

We've still got a little time to 'hammer out the details' on this

Hi waste and others. I had my daddy over and he says it's probly best to go with mark's/mas's set up so that's what we will do.

Now. Question time.

We all know deep water is cold! Brrrr I want to use solar heat to warm the pool. I'll be setting up the solar panels on the garage roof which is closest to the deep end. Can I plumb my low returns to be the dedicated line for solar? I'm thinking it would be better to heat from the bottom up.

Whatjathink? :-D

Now. Question time.

We all know deep water is cold! Brrrr I want to use solar heat to warm the pool. I'll be setting up the solar panels on the garage roof which is closest to the deep end. Can I plumb my low returns to be the dedicated line for solar? I'm thinking it would be better to heat from the bottom up.

Whatjathink? :-D

- May 3, 2007

- 16,833

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Casey,

Just a few modifications to what Waste drew of what I had suggested (btw thanks for drawing that Waste). You can keep the “deep†return in the shallow end if you want and it may actually help circulation, but I would put it on the opposite wall from where it is currently located. Having a return which is counter rotational to the flow could present a problem in the shallow end. In the deep end, you can put the return deep enough where it probably doesn't matter much (although I would still align it with the circulation) but in the shallow end, I would keep the return in the direction of the general circulation which is counter clockwise.

Also, for the steps, you might consider staggering the two returns so they don’t face each other and you can also make them at slightly different levels. So one of the returns could be at the level of the first step and between the first and second steps and second return could be lower between the second and third steps. This would ensure that all steps get at least some of the dirt blown off.

Also, where do you plan on having the equipment pad? For the setup I proposed, it may make a difference on how the lines are plumbed together and the line size. It may make more sense to have separate lines to each return depending on the equipment location. The stair returns can easily be plumbed together so that is not so much of an issue. But the other returns are spaced fairly far apart so it may not make too much sense in combining them. Or you can always combine them at some mid-way point. Using 5 x 1 ½†lines has about the same head loss as 3 x 2†lines so that is always an option. Of course, 5 x 2†lines have less head loss but it really doesn’t by you much in head loss reduction (about 3% to 5%). Most of the head loss will end being in the pad equipment and solar so it probably doesn’t matter all that much. Also, having the lines approximately the same length can help equalize flow although that can also be accomplished by ball valves at the pad.

As to having a dedicated return for the solar, that presents a few problems. First, if you have all of the water going through the solar, then skimming and chlorination will stop, depending on how you chlorinate and how it is plumbed. If you split the return so that some of the water goes through solar and the rest through the other returns, then the pump speed will have to be higher to support the flow rates required for solar and skimming so you will sacrifice some of the energy efficiency of the pump.

There are some setups where it may make sense to have a separate solar return but given that you have an Intelliflo pump, it may not make sense in your case. Given you can optimized the speed of the pump, it may make more sense to send all of the water through the solar at 40-60 GPM and return all of the water through all of the returns. An equal 5-way split, would mean about 8-12 GPM per return (half for that for each step) which is not a lot but should be enough for adequate skimming.

Also, I wanted to point out that no matter how you configure the skimmers and returns, skimming action decreases with a decrease in flow rates. So what most Intelliflo owners find is that there is a minimum flow rate at which the skimmers will work properly.

There are a lot of options you can make so I applaud your decision to put some effort and thought into the choices you are making. It will be worth it in the long run. Plumbing is usually an after thought for most pool builders (of course except for Waste and some others on TFP) and they usually do what is easiest/cheapest for them and not necessarily the best choice.

Just a few modifications to what Waste drew of what I had suggested (btw thanks for drawing that Waste). You can keep the “deep†return in the shallow end if you want and it may actually help circulation, but I would put it on the opposite wall from where it is currently located. Having a return which is counter rotational to the flow could present a problem in the shallow end. In the deep end, you can put the return deep enough where it probably doesn't matter much (although I would still align it with the circulation) but in the shallow end, I would keep the return in the direction of the general circulation which is counter clockwise.

Also, for the steps, you might consider staggering the two returns so they don’t face each other and you can also make them at slightly different levels. So one of the returns could be at the level of the first step and between the first and second steps and second return could be lower between the second and third steps. This would ensure that all steps get at least some of the dirt blown off.

Also, where do you plan on having the equipment pad? For the setup I proposed, it may make a difference on how the lines are plumbed together and the line size. It may make more sense to have separate lines to each return depending on the equipment location. The stair returns can easily be plumbed together so that is not so much of an issue. But the other returns are spaced fairly far apart so it may not make too much sense in combining them. Or you can always combine them at some mid-way point. Using 5 x 1 ½†lines has about the same head loss as 3 x 2†lines so that is always an option. Of course, 5 x 2†lines have less head loss but it really doesn’t by you much in head loss reduction (about 3% to 5%). Most of the head loss will end being in the pad equipment and solar so it probably doesn’t matter all that much. Also, having the lines approximately the same length can help equalize flow although that can also be accomplished by ball valves at the pad.

As to having a dedicated return for the solar, that presents a few problems. First, if you have all of the water going through the solar, then skimming and chlorination will stop, depending on how you chlorinate and how it is plumbed. If you split the return so that some of the water goes through solar and the rest through the other returns, then the pump speed will have to be higher to support the flow rates required for solar and skimming so you will sacrifice some of the energy efficiency of the pump.

There are some setups where it may make sense to have a separate solar return but given that you have an Intelliflo pump, it may not make sense in your case. Given you can optimized the speed of the pump, it may make more sense to send all of the water through the solar at 40-60 GPM and return all of the water through all of the returns. An equal 5-way split, would mean about 8-12 GPM per return (half for that for each step) which is not a lot but should be enough for adequate skimming.

Also, I wanted to point out that no matter how you configure the skimmers and returns, skimming action decreases with a decrease in flow rates. So what most Intelliflo owners find is that there is a minimum flow rate at which the skimmers will work properly.

There are a lot of options you can make so I applaud your decision to put some effort and thought into the choices you are making. It will be worth it in the long run. Plumbing is usually an after thought for most pool builders (of course except for Waste and some others on TFP) and they usually do what is easiest/cheapest for them and not necessarily the best choice.

Hi mas.

Some pics to start out with.

This is where the pool will go, with the deep end closest to the garage and shallow end closer to where I'm standing. I'd like to use the solar panels on the garage roof.

The home for the future pump pad will be behind the garage here.

And the pool looking towards back of yard, deep end would be closest to where I'm standing now.

I am going to go back and read up a bit more but wanted to post the pics so you and others could help me study up. I'd like to do it the right way the first way and have optimal use of my skimmers and returns. You know, the best bang for my buck! 8)

Some pics to start out with.

This is where the pool will go, with the deep end closest to the garage and shallow end closer to where I'm standing. I'd like to use the solar panels on the garage roof.

The home for the future pump pad will be behind the garage here.

And the pool looking towards back of yard, deep end would be closest to where I'm standing now.

I am going to go back and read up a bit more but wanted to post the pics so you and others could help me study up. I'd like to do it the right way the first way and have optimal use of my skimmers and returns. You know, the best bang for my buck! 8)

mas985 said:Casey,

Just a few modifications to what Waste drew of what I had suggested (btw thanks for drawing that Waste). You can keep the “deep†return in the shallow end if you want and it may actually help circulation, but I would put it on the opposite wall from where it is currently located. Having a return which is counter rotational to the flow could present a problem in the shallow end. In the deep end, you can put the return deep enough where it probably doesn't matter much (although I would still align it with the circulation) but in the shallow end, I would keep the return in the direction of the general circulation which is counter clockwise.

I was wondering if it should go on the opposite wall. Thanks for clarifying that. Would it be better to just move the low returns in the deep end tooon the other side then? If so, I can do that. There's no sense in messing with the circulation.

Also, for the steps, you might consider staggering the two returns so they don’t face each other and you can also make them at slightly different levels. So one of the returns could be at the level of the first step and between the first and second steps and second return could be lower between the second and third steps. This would ensure that all steps get at least some of the dirt blown off.

Gotcha. I think I have to pre drill those myself.

Also, where do you plan on having the equipment pad? For the setup I proposed, it may make a difference on how the lines are plumbed together and the line size. It may make more sense to have separate lines to each return depending on the equipment location. The stair returns can easily be plumbed together so that is not so much of an issue. But the other returns are spaced fairly far apart so it may not make too much sense in combining them. Or you can always combine them at some mid-way point. Using 5 x 1 ½†lines has about the same head loss as 3 x 2†lines so that is always an option. Of course, 5 x 2†lines have less head loss but it really doesn’t by you much in head loss reduction (about 3% to 5%). Most of the head loss will end being in the pad equipment and solar so it probably doesn’t matter all that much. Also, having the lines approximately the same length can help equalize flow although that can also be accomplished by ball valves at the pad.

Dad and I were discussing the size of return lines, 1 1/2" or 2". I thought I'd do 2" for returns but if you think 1 1/2" would be better, I could do that. Dad said I'd get more pressure from 1 1/2".

As to having a dedicated return for the solar, that presents a few problems. First, if you have all of the water going through the solar, then skimming and chlorination will stop, depending on how you chlorinate and how it is plumbed. If you split the return so that some of the water goes through solar and the rest through the other returns, then the pump speed will have to be higher to support the flow rates required for solar and skimming so you will sacrifice some of the energy efficiency of the pump.

There are some setups where it may make sense to have a separate solar return but given that you have an Intelliflo pump, it may not make sense in your case. Given you can optimized the speed of the pump, it may make more sense to send all of the water through the solar at 40-60 GPM and return all of the water through all of the returns. An equal 5-way split, would mean about 8-12 GPM per return (half for that for each step) which is not a lot but should be enough for adequate skimming.

So, are you saying it'd be better to run the solar through all the returns instaed of having one dedicated deep end return for the solar?

Also, I wanted to point out that no matter how you configure the skimmers and returns, skimming action decreases with a decrease in flow rates. So what most Intelliflo owners find is that there is a minimum flow rate at which the skimmers will work properly.

So, I will have to set the pump at an average <give or take> but still be able to feel it suck right? If I set it too low, I'll lose all skimming action but if I keep it up, but not high, It'll be able to still skim?

There are a lot of options you can make so I applaud your decision to put some effort and thought into the choices you are making. It will be worth it in the long run. Plumbing is usually an after thought for most pool builders (of course except for Waste and some others on TFP) and they usually do what is easiest/cheapest for them and not necessarily the best choice.

Again, I want to do it right. There is no sense in my mind to throw it all together and find out it doesn't do what I need it to do.If I am unclear or whatever, set me straight!

I appreciate everything you guys are doing for me to get my pool!

Have any of you guys concidered heat bending 20ft lengths of hard pipe? I think this is what I will do when I build a pool for myself. Right now I use tigerflex for speed, but hydralic efficiency would be a lot better with heat bent pipe and using 20ft lengths would really reduce the number of glue joints underground. That is the only plus I see to flex pipe other than speed, just having one glue joint. Also, I usually just put one return in the steps. Make sure those deep returns are only about halfway down the wall, when you get towards the bottom they are a wet mess to plug while blowing out, and I just dont trust the check valve plugs.

Hi Mevan.

You gonna come pressurize the plumbing for me when it's time? I'm just 60 miles south of you!

O, and wouldn't heating the PVC make it weak on the outside corner? Just asking.

You gonna come pressurize the plumbing for me when it's time? I'm just 60 miles south of you!

O, and wouldn't heating the PVC make it weak on the outside corner? Just asking.

Casey said:Hi Mevan.

You gonna come pressurize the plumbing for me when it's time? I'm just 60 miles south of you!

O, and wouldn't heating the PVC make it weak on the outside corner? Just asking.

Casey, if the timing's right I'll close your pool when we go to see my wife's cousins in Kimberton

Please be nice to Matt, he's a good guy and has a lot of helpful info to give here

I hope you know how much I care about you and your pool build :-D

- May 3, 2007

- 16,833

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Casey said:I was wondering if it should go on the opposite wall. Thanks for clarifying that. Would it be better to just move the low returns in the deep end tooon the other side then? If so, I can do that. There's no sense in messing with the circulation.

I don't think a deep return is really necessary in the shallow end but I wanted to give you the option if you really wanted that. Having two in the deep end is fine and you could probably get away with just one if you really wanted. But see my comments at the end.

Dad and I were discussing the size of return lines, 1 1/2" or 2". I thought I'd do 2" for returns but if you think 1 1/2" would be better, I could do that. Dad said I'd get more pressure from 1 1/2".

Bigger pipe is always better, I was just giving you some options. Also, you will lose more pressure with 1 1/2" and have higher filter pressure but actually have less pressure at the return eyeball so overall flow rates will be slightly less with 1 ½†line. So again, 2" would be better.

So, are you saying it'd be better to run the solar through all the returns instaed of having one dedicated deep end return for the solar?

Yes, given your setup and desire to run at the lowest flow rates possible, I would recommend sending everything back through all of the returns.

So, I will have to set the pump at an average <give or take> but still be able to feel it suck right? If I set it too low, I'll lose all skimming action but if I keep it up, but not high, It'll be able to still skim?

Yes, I figure for a good match to solar and return skimming, somewhere in the range of 40-60 GPM should work well. It may take some experimentation but it should be in that range

Again, I want to do it right. There is no sense in my mind to throw it all together and find out it doesn't do what I need it to do.If I am unclear or whatever, set me straight!

I appreciate everything you guys are doing for me to get my pool!

Given where you plan the pad, here is what I would do.

Use 2†lines for each skimmer and the main drain pair (3 total) back to the pad each line with a control ball valve into a 2 ½†manifold. In fact, if you can go with all 2 ½†line on the pad, that would be better. Most equipment these days can take 2†or 2 ½†plumbing on the pad.

Combine the step returns with one 2†line back to the pad. Use 2 deep end returns, combine them somewhere near the pool and take one 2†line back to the pad. For each of the two surface returns, use a 2†line all the way to the pad. So you will have 4 2†lines back to the pad. Combine each line into a 2 ½†manifold with ball valves on each line.

This setup should give plenty of flow back to the pool and allow for some optimization as well.

waste said:Casey said:Hi Mevan.

You gonna come pressurize the plumbing for me when it's time? I'm just 60 miles south of you!

O, and wouldn't heating the PVC make it weak on the outside corner? Just asking.

Casey, if the timing's right I'll close your pool when we go to see my wife's cousins in Kimberton(I also want to show her Pottstown and the Hill School) Unfortunately, I think you're on the wast side of Pa - I'll be going to Jamestown NY for Thanksgiving so maybe we can do it then :-D

Please be nice to Matt, he's a good guy and has a lot of helpful info to give here:!:

I hope you know how much I care about you and your pool build :-D

That would be so cool waste! Yes, I'm in south western PA. <Fayette County> I'm sure we could swing something.

I have been thinking about Mevan for some time even though I haven't really said anything except for that emotional out burst a couple post up and he is from Pittsburgh.

waste, I want you to know that I care about you and this build too even though we've never personally met <may change in the future>, I feel like I've known ya forever! I'd love to meet you! I'd love to have ya over with the wife and dd and chill by the pool we put together TOGETHER! We could drink a few beers

er maybe more than a few and talk about how great the pool turned out! Don't worry about rooms! I have two extra rooms upstairs and a huge sectional you might have to share with the dog. Lots of room though!

er maybe more than a few and talk about how great the pool turned out! Don't worry about rooms! I have two extra rooms upstairs and a huge sectional you might have to share with the dog. Lots of room though! I am really enjoying pool school!

When I put up my above ground a couple years ago, my neighbor said I should go into business and do ingrounds too... I said, WTH am I nuts? I guess I answered my own question!

mas985 said:Given where you plan the pad, here is what I would do.

Use 2†lines for each skimmer and the main drain pair (3 total) back to the pad each line with a control ball valve into a 2 ½†manifold. In fact, if you can go with all 2 ½†line on the pad, that would be better. Most equipment these days can take 2†or 2 ½†plumbing on the pad.

Combine the step returns with one 2†line back to the pad. Use 2 deep end returns, combine them somewhere near the pool and take one 2†line back to the pad. For each of the two surface returns, use a 2†line all the way to the pad. So you will have 4 2†lines back to the pad. Combine each line into a 2 ½†manifold with ball valves on each line.

This setup should give plenty of flow back to the pool and allow for some optimization as well.

Sounds good mas! Thank you for your expertise!!

I didnt realize we were so close. We might be able to work something out. Unfortuantly my company does not pressure test lines, we fill the pool before backfill to prevent wall pushing during that time and visually inspect the lines for leaks. Pressure testing would be a much more professional way of doing it. I need to make one soon anyway. We use american leak detection for all of our work in that area as well but its a nice thing to have. Heat bending pipe doesnt weaken it as long as you make nice long sweeps like you are supposed to. Gunite builders do this a lot. I think most are using tigerflex now for convenience though. I bend my conduit with a simple heat gun, but that only works well on thinner pipe.

It sounds like your plumber is a little older, make sure he is priming and glueing, I have noticed a lot of older guys try to treat pvc like ABS pipe. I prefer lasco's union slide valves to the ball valves that are currently on the market, you might want to think about those. If automation might be something you want to concider down the line, take the expense and order a few waterways or jandy 3 way 2 inch valves to seperate any slide lines or water features from the source lines.

It sounds like your plumber is a little older, make sure he is priming and glueing, I have noticed a lot of older guys try to treat pvc like ABS pipe. I prefer lasco's union slide valves to the ball valves that are currently on the market, you might want to think about those. If automation might be something you want to concider down the line, take the expense and order a few waterways or jandy 3 way 2 inch valves to seperate any slide lines or water features from the source lines.

oh and one more thing, I havent heard a lot of mention during this plumbing chat on the virginia graeme baker act. Keep these new regulations in mind. Since im not doing new construction this year I havent researched it as much as I should but when using main drains and sidewall suctions you must observe the fps guidlines. In order to do be sure to buy compliant drains, run them in no smaller than 2 inch line, tie them together between each other, not in line, and do not neck down the pipe inbetween drains. Hold to the size of the root line between each. We have been running ours in 2.5 inch pipe to ensure we are compliant. Remember though, I have not been very up to date on this so research it, dont take my word on it.

I believe my Pool Store is compliant. She said the MD is up to standard cuz they had to switch a few years ago or something like that.

Thanks for your reply Mevan. My dad knows his plumbing and will be priming and gluing all joints of plumbing the way he always has.

Thanks for your reply Mevan. My dad knows his plumbing and will be priming and gluing all joints of plumbing the way he always has.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.