- Nov 26, 2013

- 168

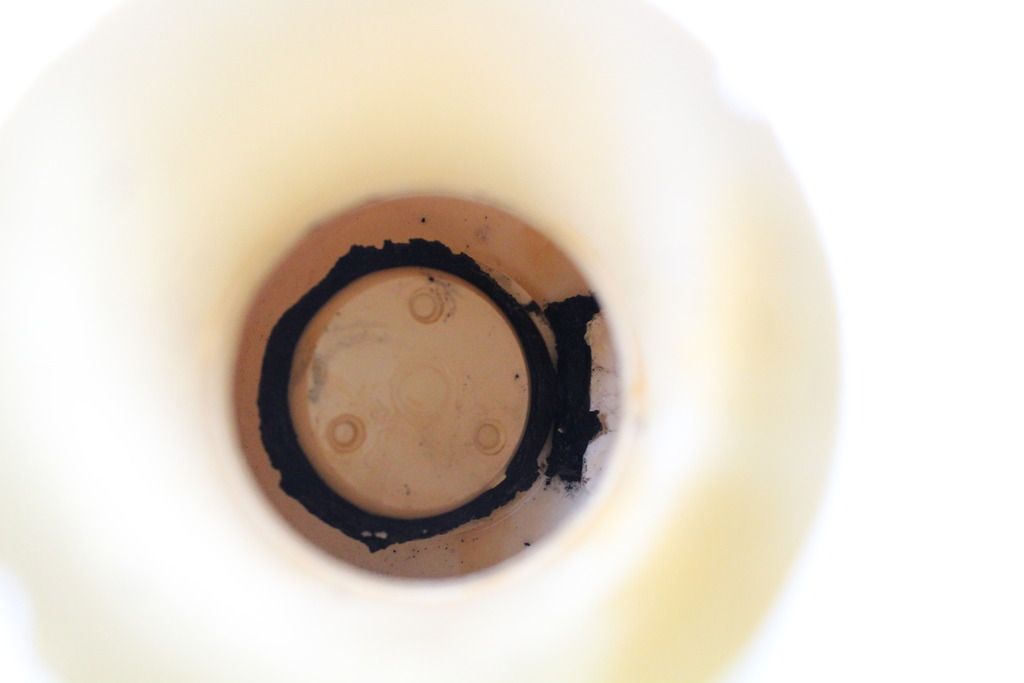

I've done some PVC work, but this fix is a bit of a puzzle. My check valve is blocking flow in the wrong direction. I can explain why I know this, but that's a distraction.

Explaining the picture. This is all pressure side. The line from the pump comes in from the bottom, feeds into my multi-port valve and sand filter. It comes out, pass a tee which feeds my booster pump then an elbow, union, elbow and into my worthless heater. It comes out of my heater, into two elbows, then the broken check valve, my tablet feeder, another union and off to the pool.

The heater works just fine, but I never use it. It costs way too much for how little it does.

I'm thinking of cutting the pipe right next to the first elbow. This lets me keep the booster connection, but I can unscrew it from the multiport and reattach it with dope, fixing the minor leak that's there. I'd cut the other line right next to the check valve on the feeder side.

To put it back together, starting near the booster, I'd put a union on, then a elbow to the right, a straight run to past the feeder, then elbow up, straight, and elbow into the feeder line.

Do this seem like a good idea? I'm not against spending more money on unions and such. Thanks!

Explaining the picture. This is all pressure side. The line from the pump comes in from the bottom, feeds into my multi-port valve and sand filter. It comes out, pass a tee which feeds my booster pump then an elbow, union, elbow and into my worthless heater. It comes out of my heater, into two elbows, then the broken check valve, my tablet feeder, another union and off to the pool.

The heater works just fine, but I never use it. It costs way too much for how little it does.

I'm thinking of cutting the pipe right next to the first elbow. This lets me keep the booster connection, but I can unscrew it from the multiport and reattach it with dope, fixing the minor leak that's there. I'd cut the other line right next to the check valve on the feeder side.

To put it back together, starting near the booster, I'd put a union on, then a elbow to the right, a straight run to past the feeder, then elbow up, straight, and elbow into the feeder line.

Do this seem like a good idea? I'm not against spending more money on unions and such. Thanks!