I've been spending hours out there perspiring with tools, and can't seem to fix my problem.

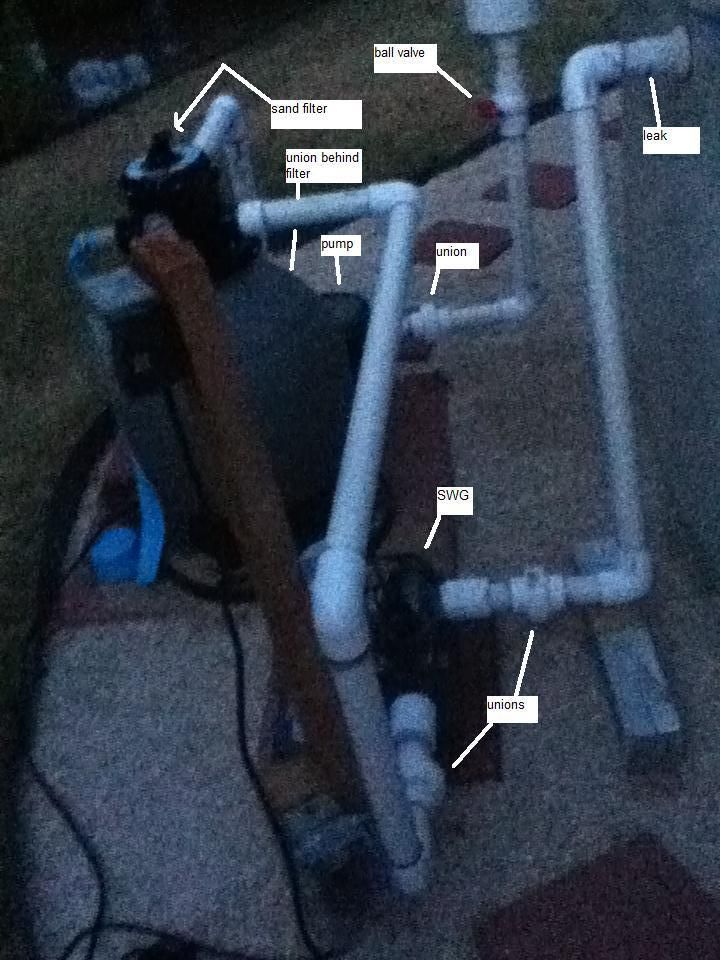

It all started because I took today off from work to install my new salt water generator. I wanted to replace all my flexible tubing with rigid PVC, and so I removed the old plumbing to get a good look at the threaded adapters so I'd know what parts to buy at home depot.

To make it easier to move my sand filter, I removed the drain plug to let water drain out. Unknown to me, it's actually a plug within a plug, and when I unscrewed the outer plug, both plugs unscrewed, and suddenly about a quart of sand leaked out through the drain plug. I immediately stuck the plug in there, but the damage is done.

I called the place that sold me the pool, and he said by taking off the inner plug, a nut would have come loose on the inside that holds it in place, and so now what I have to do is take apart the filter, evacuate all the sand, reattach the nut that holds the drain plug in place, and put the sand back in again.

The problem is: to do this, I have to remove the collar that's held in place by two bolts and two square nuts. The nuts are recessed inside a slot so the only way to do this is with a philips screwdriver and unscrew the bolts. That's what I've spent hours attempting to to. I use all the strength I have, and I can even see the collars start to bend under my force, and those bolts won't budge. I'm doing it counterclockwise - they're just on really tight.

At this point, both bolts are getting partially stripped so it's getting harder to even get a good hold with my screwdrivers, and I've tried every screwdriver in the house, and nothing works.

I thought maybe I should use a hacksaw to cut one of the bolts in half and buy a new bolt to replace it, but it's hard to get my hacksaw in that small space. I'm running out of ideas on what to do, and now I have no ability to circulate my pool water until I solve this.

It all started because I took today off from work to install my new salt water generator. I wanted to replace all my flexible tubing with rigid PVC, and so I removed the old plumbing to get a good look at the threaded adapters so I'd know what parts to buy at home depot.

To make it easier to move my sand filter, I removed the drain plug to let water drain out. Unknown to me, it's actually a plug within a plug, and when I unscrewed the outer plug, both plugs unscrewed, and suddenly about a quart of sand leaked out through the drain plug. I immediately stuck the plug in there, but the damage is done.

I called the place that sold me the pool, and he said by taking off the inner plug, a nut would have come loose on the inside that holds it in place, and so now what I have to do is take apart the filter, evacuate all the sand, reattach the nut that holds the drain plug in place, and put the sand back in again.

The problem is: to do this, I have to remove the collar that's held in place by two bolts and two square nuts. The nuts are recessed inside a slot so the only way to do this is with a philips screwdriver and unscrew the bolts. That's what I've spent hours attempting to to. I use all the strength I have, and I can even see the collars start to bend under my force, and those bolts won't budge. I'm doing it counterclockwise - they're just on really tight.

At this point, both bolts are getting partially stripped so it's getting harder to even get a good hold with my screwdrivers, and I've tried every screwdriver in the house, and nothing works.

I thought maybe I should use a hacksaw to cut one of the bolts in half and buy a new bolt to replace it, but it's hard to get my hacksaw in that small space. I'm running out of ideas on what to do, and now I have no ability to circulate my pool water until I solve this.