Keep all postings on your pool and any renovations in one thread as it makes it easier to follow. Casey~

Hey Guys, this is my first post on the forum but I've been lurking awhile and looking up information for awhile now. Its a great community and I'm excited to share my project. I wish I'd started this thread sooner, because now I feel like I've got a long story to share. I'll break it up into a longer post eventually, Fortunately I've documented it all and taken lots of pictures

But first a question; I've read a lot online and here about the 'right' mix for plaster; using white quartz sand or marble and portland cement. I'm doing the replastering myself and want to do it in a darker tone. My goal is to have it a dark grey/black, I feel like it'll help warm the pool a lot. I was wondering if anyone knew reasons not to use plain portland cement, and an aggregate like silica or play sand, and possible a cement tinting agent, like the quickrete liquid dye.

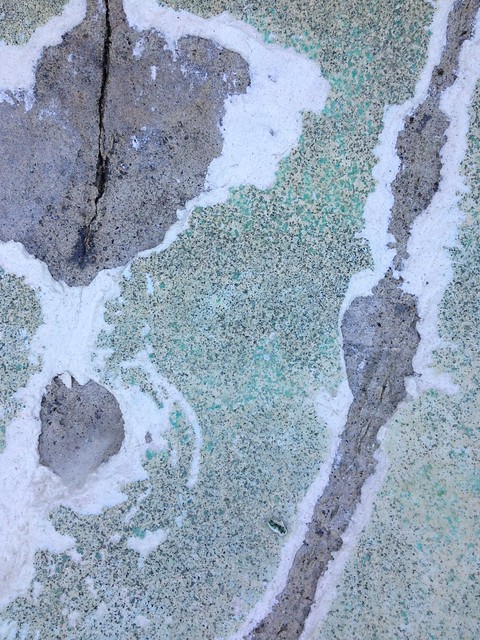

The other thing is that while i've removed the bad/delaminated plaster, I haven't removed *all* the old plaster, so I'll be completely patching the spots that need it, but also doing a 'skim' coat of about 1/8 to 1/4inch over the old and want to be sure the new coat adheres. I've read about acid washing and wetting the surrounding cement to prevent it drying unevenly, but other pointers and advice is appreciated.

I'm unsure about the dye/tint since I may have to mix it in multiple batches and getting the ratio to match may be tricky, and I'm unsure how the dye will last long-term etc. So I'm very on the fence about it, and the samples I've mixed of sand/portland look like they might be grey enough for my taste.

Anyone know a reason I shouldn't use sand and plain portland, any experience with tint/dye, anyone done 'skim' coat over old plaster, any other advice?

thanks,

-brad

Hey Guys, this is my first post on the forum but I've been lurking awhile and looking up information for awhile now. Its a great community and I'm excited to share my project. I wish I'd started this thread sooner, because now I feel like I've got a long story to share. I'll break it up into a longer post eventually, Fortunately I've documented it all and taken lots of pictures

But first a question; I've read a lot online and here about the 'right' mix for plaster; using white quartz sand or marble and portland cement. I'm doing the replastering myself and want to do it in a darker tone. My goal is to have it a dark grey/black, I feel like it'll help warm the pool a lot. I was wondering if anyone knew reasons not to use plain portland cement, and an aggregate like silica or play sand, and possible a cement tinting agent, like the quickrete liquid dye.

The other thing is that while i've removed the bad/delaminated plaster, I haven't removed *all* the old plaster, so I'll be completely patching the spots that need it, but also doing a 'skim' coat of about 1/8 to 1/4inch over the old and want to be sure the new coat adheres. I've read about acid washing and wetting the surrounding cement to prevent it drying unevenly, but other pointers and advice is appreciated.

I'm unsure about the dye/tint since I may have to mix it in multiple batches and getting the ratio to match may be tricky, and I'm unsure how the dye will last long-term etc. So I'm very on the fence about it, and the samples I've mixed of sand/portland look like they might be grey enough for my taste.

Anyone know a reason I shouldn't use sand and plain portland, any experience with tint/dye, anyone done 'skim' coat over old plaster, any other advice?

thanks,

-brad