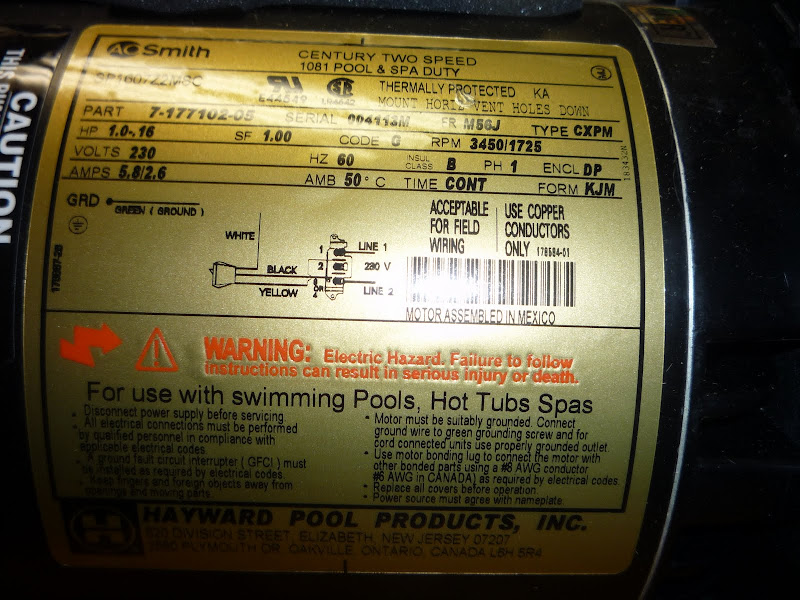

The diagram on the pump is unreadable.

It's basically this diagram:

I have two hot wires, 120V each, verified with my volt meter. I can make out running one hot wire to line 3 or 4. Where do I run the other? 1 or 2? I can't tell from this diagram. There in nothing labeled LINE in the pump. Just 1, 2, 3, 4 and ground. I put my hots on 4 and 2, pump ran, but when I switched the toggle, it tripped the breaker... Tripped it to the point where I had to change it. so it's not 2.

Help.

It's basically this diagram:

I have two hot wires, 120V each, verified with my volt meter. I can make out running one hot wire to line 3 or 4. Where do I run the other? 1 or 2? I can't tell from this diagram. There in nothing labeled LINE in the pump. Just 1, 2, 3, 4 and ground. I put my hots on 4 and 2, pump ran, but when I switched the toggle, it tripped the breaker... Tripped it to the point where I had to change it. so it's not 2.

Help.