- May 3, 2007

- 16,886

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

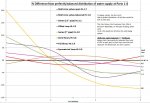

I, like most people, have long believed that plumbing loops can help balance return flow through multiple returns in a pool or spa but I was curious as to how much they really help and if there are other ways to balance return flow. So I performed a detailed analysis on 6 different plumbing configurations and I thought I would share the results.

Configuration Diagrams

Configuration Descriptions

- Multi-Line - Separate lines with valves to each of the returns going from the pad to the pool.

- Full Binary - This configuration is completely symmetrical and the plumbing to each return is identical thereby guaranteeing that each return will have the same flow rate.

- Semi-Binary - This configuration uses a single split combined with a series fed configuration and is partially symmetrical. Returns 1 & 4 will have the same flow rates and returns 2 & 3 will have the same flow rates.

- Symmetrical Loop - This configuration is similar to the Semi-Binary in that the same return pairs will have the same flow rates although the values are swapped. However, because there is extra pipe to travel through, this configuration will have slightly higher head loss.

- Offset Loop - This is probably a more common loop configuration and will tend to have more imbalanced returns than the symmetrical loop.

- 2"/2.5" Series - This is probably the most common configuration for a pool and of course has the most imbalance between the returns. But as I will show, this can be improved by increasing the feed pipe.

Pool Analysis Configuration

40' Pool Length

10' Distance between returns

2' 1.5" return pipe into pool

1" Eyeballs

2" Feed pipe unless otherwise specified

80 GPM Total flow rate split between the returns

Head loss calculated to edge of pool for all scenarios

Analysis Results

Multi-Line (Valves 100%) - Return 1-4 Flow Rates = 20.6, 20.2, 19.8, 19.5 - Head Loss = 1.7'

Multi-Line (Valves Balanced) - Return 1-4 Flow Rates = 20, 20, 20, 20 - Head Loss = 1.8'

Full Binary - Return 1-4 Flow Rates = 20, 20, 20, 20 - Head Loss = 5.6'

Semi Binary - Return 1-4 Flow Rates = 19.7, 20.3, 20.3, 19.7 - Head Loss = 4.7'

Symmetrical Loop - Return 1-4 Flow Rates = 20.3, 19.7, 19.7, 20.3 - Head Loss = 5.8'

Offset Loop - Return 1-4 Flow Rates = 21.4, 20.8, 18.7, 19.1 - Head Loss = 2.5'

Series (2" pipe) - Return 1-4 Flow Rates = 24, 20.1, 18.2, 17.7 - Head Loss = 3.5'

Series (2.5" pipe) - Return 1-4 Flow Rates = 21.9, 20, 19.1, 18.9 - Head Loss = 2.4'

Series (3" pipe) - Return 1-4 Flow Rates = 20.8, 20, 19.6, 19.5 - Head Loss = 1.9'

Observations

- The Multi-Line configuration gives the most flexibility and performance but requires a lot of piping. But keep in mind that 4x2" pipes is the equivalent of 1x3.7" pipe so not exactly apples to apples.

- The Full Binary configuration has ideal return balance but it also has the highest head loss of all the configurations.

- Semi Binary is fairly balanced but still has fairly high head loss.

- Symmetrical loop has the same balance as Semi Binary but at the cost of more head loss.

- The 2" Series has the worst balance between returns.

- The 2.5" series has similar balance to the offset loop and slightly lower head loss.

But in reality, none of the configurations are that imbalanced and probably would never be an issue. So in most cases, this is probably nothing to really be concerned about unless you are feeding a water feature that requires exactly the same look at all the returns.

In addition, I looked at a 8 jet spa using the Semi Binary configuration with 4 jets in each series after the split. Assuming 2.5" pipe is used, there is so little head loss in the 2.5" pipe between the jets compared to the head loss in the jet itself, that the flow rates out of the jets are nearly identical even without a loop. So this shows that loops are not really required for spas either.

Comments/questions from the forum are always welcomed.

Configuration Diagrams

Configuration Descriptions

- Multi-Line - Separate lines with valves to each of the returns going from the pad to the pool.

- Full Binary - This configuration is completely symmetrical and the plumbing to each return is identical thereby guaranteeing that each return will have the same flow rate.

- Semi-Binary - This configuration uses a single split combined with a series fed configuration and is partially symmetrical. Returns 1 & 4 will have the same flow rates and returns 2 & 3 will have the same flow rates.

- Symmetrical Loop - This configuration is similar to the Semi-Binary in that the same return pairs will have the same flow rates although the values are swapped. However, because there is extra pipe to travel through, this configuration will have slightly higher head loss.

- Offset Loop - This is probably a more common loop configuration and will tend to have more imbalanced returns than the symmetrical loop.

- 2"/2.5" Series - This is probably the most common configuration for a pool and of course has the most imbalance between the returns. But as I will show, this can be improved by increasing the feed pipe.

Pool Analysis Configuration

40' Pool Length

10' Distance between returns

2' 1.5" return pipe into pool

1" Eyeballs

2" Feed pipe unless otherwise specified

80 GPM Total flow rate split between the returns

Head loss calculated to edge of pool for all scenarios

Analysis Results

Multi-Line (Valves 100%) - Return 1-4 Flow Rates = 20.6, 20.2, 19.8, 19.5 - Head Loss = 1.7'

Multi-Line (Valves Balanced) - Return 1-4 Flow Rates = 20, 20, 20, 20 - Head Loss = 1.8'

Full Binary - Return 1-4 Flow Rates = 20, 20, 20, 20 - Head Loss = 5.6'

Semi Binary - Return 1-4 Flow Rates = 19.7, 20.3, 20.3, 19.7 - Head Loss = 4.7'

Symmetrical Loop - Return 1-4 Flow Rates = 20.3, 19.7, 19.7, 20.3 - Head Loss = 5.8'

Offset Loop - Return 1-4 Flow Rates = 21.4, 20.8, 18.7, 19.1 - Head Loss = 2.5'

Series (2" pipe) - Return 1-4 Flow Rates = 24, 20.1, 18.2, 17.7 - Head Loss = 3.5'

Series (2.5" pipe) - Return 1-4 Flow Rates = 21.9, 20, 19.1, 18.9 - Head Loss = 2.4'

Series (3" pipe) - Return 1-4 Flow Rates = 20.8, 20, 19.6, 19.5 - Head Loss = 1.9'

Observations

- The Multi-Line configuration gives the most flexibility and performance but requires a lot of piping. But keep in mind that 4x2" pipes is the equivalent of 1x3.7" pipe so not exactly apples to apples.

- The Full Binary configuration has ideal return balance but it also has the highest head loss of all the configurations.

- Semi Binary is fairly balanced but still has fairly high head loss.

- Symmetrical loop has the same balance as Semi Binary but at the cost of more head loss.

- Offset loop has worse balance than the symmetrical but better than the 2" Series.The first three scenarios all suffer from the long feed pipe to the center of the pool which adds a significant amount of head loss. However, if the equipment is located closer to the middle of the pool, these configurations might be a better choice.

- The 2" Series has the worst balance between returns.

- The 2.5" series has similar balance to the offset loop and slightly lower head loss.

But in reality, none of the configurations are that imbalanced and probably would never be an issue. So in most cases, this is probably nothing to really be concerned about unless you are feeding a water feature that requires exactly the same look at all the returns.

In addition, I looked at a 8 jet spa using the Semi Binary configuration with 4 jets in each series after the split. Assuming 2.5" pipe is used, there is so little head loss in the 2.5" pipe between the jets compared to the head loss in the jet itself, that the flow rates out of the jets are nearly identical even without a loop. So this shows that loops are not really required for spas either.

Comments/questions from the forum are always welcomed.

Last edited: