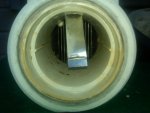

Just replaced my Single speed pump with a 2-speed this week, the new pump is working great but on the low speed I'm not getting enough flow for my IntelliChlor IC-40. I think it might be an issue with my plumbing, at the IC-40 and at the pump. As you can see with the photos I have a 90 degree elbow right before the IC-40 and I think on the low speed of the pump it's not enough flow, plus it's running through the heating before that from the filter. I'm wondering if I re-plumbed just before the inlet of the IC-40 a straight piece of pipe 12 inches or more if that would help. Not sure what to do with the plumbing before the inlet of my pump but I don't like double 90 degree elbows at all. Any ideas? Or am I stuck to not being able to use the low speed of my pump with IC-40?

Thank you

Thank you