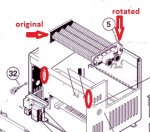

I purchased a used Hayward 350 Millivolt to replace a broken very old heater. I am getting ready to move my pool equipment and install all new valves, pump and the heater. The heater outlets need to be on the other side and the manual states these are reversible. I followed the manual, removed all the upper shielding to get to the Heat Exchanger, the manual says basically to disconnect wires and switches, remove the Front Header and rotate the exchanger 180 degrees (NOT to flip) and then reinstall. This seems to work fine with the front header as all threaded holes will realign with the various switches and the wiring can reroute thru the side panel to the controls. The problem is the rear header, it has a Pressure switch with a tube on one side and there is no corresponding threaded outlet on the opposite side. When I rotate the exchanger, the pressure switch fitting is on the opposite side away from the controls and the switch cannot be reconnected. I see 2 ways to correct this: 1. Flip the exchange over so the fitting will end up on the correct side or 2. remove the rear header and turn it over. Nowhere in the instructions does it mention removing the rear header for any reason and the instructions explicitly state:"CAUTION: Do not flip it (Heat Exchanger) over. The Heat Exchanger will be damaged if installed incorrectly", they only want you to rotate it 180.

I see there is no physical difference between one side of the heat exchanger to the other, the only difference is in the ports on the headers and as long as they are located properly I don't see how the exchanger would be damaged. So do I do option 1 or 2? Anybody have experience with these?

I see there is no physical difference between one side of the heat exchanger to the other, the only difference is in the ports on the headers and as long as they are located properly I don't see how the exchanger would be damaged. So do I do option 1 or 2? Anybody have experience with these?