Long story short, but my PB really screwed my on this one...

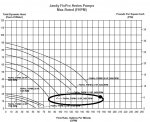

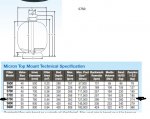

The design called for my HeatPump to be able to run on Low Speed with my 2 SP Pump, see below for details, but it is a Jandy Flo Pro

http://www.zodiacpoolsystems.com/Products/Pumps/Single-Two-Speed-Pumps/FloPro.aspx

Well, it appeared that MAYBE it would, but in all reality I do not have enough flow on low speed to run the HP. Even though the pump spec says it is putting out 55 GPM or so on low, in all reality it must really be less than 30 GPM in the real world.

So I told my PB it is not working and I think I need the 1.5 HP. He said fine, but I can't return the BRAND NEW 2 DAY old 1 HP and I would have to buy another 1.5 HP pump and then pay to swap it out.

Well, that is total Crud...but it seems like I won't win this one (so much for any references he might get - wonder why these guys are so short sited)

Anyways...does anyone know if I can just SWAP the motors out and I guess I could try to sell the 1HP, or is that insane thinking and I just have to suck it up and spend another $500.

Or any other ideas - let them fly!

Thanks in advance!

The design called for my HeatPump to be able to run on Low Speed with my 2 SP Pump, see below for details, but it is a Jandy Flo Pro

http://www.zodiacpoolsystems.com/Products/Pumps/Single-Two-Speed-Pumps/FloPro.aspx

Well, it appeared that MAYBE it would, but in all reality I do not have enough flow on low speed to run the HP. Even though the pump spec says it is putting out 55 GPM or so on low, in all reality it must really be less than 30 GPM in the real world.

So I told my PB it is not working and I think I need the 1.5 HP. He said fine, but I can't return the BRAND NEW 2 DAY old 1 HP and I would have to buy another 1.5 HP pump and then pay to swap it out.

Well, that is total Crud...but it seems like I won't win this one (so much for any references he might get - wonder why these guys are so short sited)

Anyways...does anyone know if I can just SWAP the motors out and I guess I could try to sell the 1HP, or is that insane thinking and I just have to suck it up and spend another $500.

Or any other ideas - let them fly!

Thanks in advance!