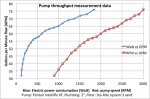

I have a 35000 gallon pool with a Sta-Rite sand filter. I recently replaced the old 3kW single-speed pump with a Pentair Intelliflo XF variable speed pump. Since electric rates here in California are sky-high (I pay 20c/kWh off-peak and 56 c/kWh on peak, highest tier), I am trying to minimize my electric bill without sacrificing pool pump action. Using a rola-chem flow meter, I measured water flow and power usage at various RPM settings of the pump:

[attachment=1:1m8edaay]PumpThroughput.jpg[/attachment:1m8edaay]

The power usage was read from the display on the pump. At 1000 RPM (~36GPM) I still have decent skimmer action, so at first sight there seems to be no downside to running at low speed.

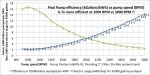

Next, I calculate the efficiency of the pump: the more gallons of water it can pump per kilowatt hour, the better. The result for various RPM settings is shows as the green line in this graph:

[attachment=0:1m8edaay]PumpEfficiency.jpg[/attachment:1m8edaay]

At 3000 RPM, the measured flow is 76 GPM (= 4560 GPH) at a usage of 1840Watt, which yields 2480 gallons per kWh. At 1000 RPM, the flow is 36 GPM at 130W, which means 16615 gallons per kWh.

The blue line shows the number of kWh needed to turn over my 35000 gallon pool once. So at 1000 RPM it costs 2.1 kWh (16.2 hours @130Watt), while at 3000RPM pumping the same 35000 gallons takes 14.1 kWh (7.7 hours @1840Watt). So it is 6.7 times cheaper to operate my pool at 1000 RPM than at 3000 RPM.

That makes a spectacular difference in operating cost, especially since the pool was about 1/3 of my electric bill with the old pump!

It seems logical that 'haste is waste'. There is more lost at high speed due to turbulence at elbow corners, in the filter or in the backwash valve. This flow resistance probably goes up with the cube of the speed, just like wind resistance. So gut feeling sais that pumping faster should always yield poorer efficiency. My measurements seem to confirm that, and then some. So it seems to make sense to run the pump always at the lowest possible RPM setting.

Question: is this correct? and did other pool owners also see this effect? Are other pools run at this very low speeds? My measurement data seem to show the opposite of what TFP expert states in the first hydraulics 101 post, where it is stated that efficiency (energy factor) goes up with flow rate:

Related posts:

Install picture of my pool equipment: http://www.troublefreepool.com/post494660.html#p494660

Hydraulics 101: http://www.troublefreepool.com/hydraulics-101-have-you-lost-your-head-t915.html

Flow meter: http://www.rola-chem.com/flowmeters.html

[attachment=1:1m8edaay]PumpThroughput.jpg[/attachment:1m8edaay]

The power usage was read from the display on the pump. At 1000 RPM (~36GPM) I still have decent skimmer action, so at first sight there seems to be no downside to running at low speed.

Next, I calculate the efficiency of the pump: the more gallons of water it can pump per kilowatt hour, the better. The result for various RPM settings is shows as the green line in this graph:

[attachment=0:1m8edaay]PumpEfficiency.jpg[/attachment:1m8edaay]

At 3000 RPM, the measured flow is 76 GPM (= 4560 GPH) at a usage of 1840Watt, which yields 2480 gallons per kWh. At 1000 RPM, the flow is 36 GPM at 130W, which means 16615 gallons per kWh.

The blue line shows the number of kWh needed to turn over my 35000 gallon pool once. So at 1000 RPM it costs 2.1 kWh (16.2 hours @130Watt), while at 3000RPM pumping the same 35000 gallons takes 14.1 kWh (7.7 hours @1840Watt). So it is 6.7 times cheaper to operate my pool at 1000 RPM than at 3000 RPM.

That makes a spectacular difference in operating cost, especially since the pool was about 1/3 of my electric bill with the old pump!

It seems logical that 'haste is waste'. There is more lost at high speed due to turbulence at elbow corners, in the filter or in the backwash valve. This flow resistance probably goes up with the cube of the speed, just like wind resistance. So gut feeling sais that pumping faster should always yield poorer efficiency. My measurements seem to confirm that, and then some. So it seems to make sense to run the pump always at the lowest possible RPM setting.

Question: is this correct? and did other pool owners also see this effect? Are other pools run at this very low speeds? My measurement data seem to show the opposite of what TFP expert states in the first hydraulics 101 post, where it is stated that efficiency (energy factor) goes up with flow rate:

Did I make a mistake somewhere? I am using a Rola-chem flow meter that I installed in the return plumbing to measure flow, and read out the power from the display on the pump. Both could have errors, but even if the absolute value is off by some, the trend likely is not.The chart also shows that the energy use of a pump is fairly linear with the flow rate. This is true for all residential pool pumps. The higher the flow rate of the pump, the more energy that is used. However, flow rates tend to increase faster than the energy use which is why the energy factor, measured as gallons per Watt-hr, of the pump increases with increasing flow rate effectively reducing the energy consumption.

Related posts:

Install picture of my pool equipment: http://www.troublefreepool.com/post494660.html#p494660

Hydraulics 101: http://www.troublefreepool.com/hydraulics-101-have-you-lost-your-head-t915.html

Flow meter: http://www.rola-chem.com/flowmeters.html