There is no doubt my filter & cleaner pool pumps are both leaking copiously at the inlet as shown below (mostly when the pumps are off):

They've been leaking from this very same spot for years:

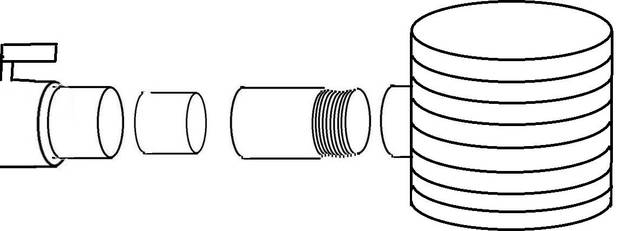

The problem is that the plumbing is pressed fitting to fitting, with 7 Jandy valves all pressed together, within a foot with nary a pipe in between:

Up until now, I've been trying the "miracle in a tube" solution - but it's really not working to plug and glue and stop up the leak.

QUESTION:

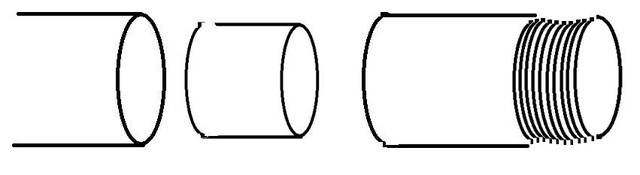

Q: Is there a magic fitting that I can slip into the inlet that will allow me to fix this incessant leak without having to replace either the pumps or the Jandy valves?

They've been leaking from this very same spot for years:

The problem is that the plumbing is pressed fitting to fitting, with 7 Jandy valves all pressed together, within a foot with nary a pipe in between:

Up until now, I've been trying the "miracle in a tube" solution - but it's really not working to plug and glue and stop up the leak.

QUESTION:

Q: Is there a magic fitting that I can slip into the inlet that will allow me to fix this incessant leak without having to replace either the pumps or the Jandy valves?