The shell to my pool was shot last week and one of the skimmer frames did not get filled with gunite. I am an owner builder so I am ultimately responsible. I noticed it was not done and told the guys at 2 different times and they said they would get it, but I guess they forgot, and by the third time I reminded them I guess it was too late because all they did was pour 2 bucket fulls of gunite into the hole and leave. I have talked to 2 different people that are in the business about this and they say it is a serious mistake and there is no good fix for it as it will be a source of leaks. To make matters worse the guy that owns the company that did the work had heart surgery the day after and I cannot talk to him for at least another week. I don't know if I should go ahead and be doing something about this or just let it sit until he can get back to work, but I don't know when that will be. Can anyone on here help me with this? I really just don't know what to do. Thanks for your help.

Pics of Repair!! Gunite guys forgot to shoot skimmers.

- Thread starter cword

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Did the interior wall and bond beam area get filled and they just forgot to fill the back/bottom of the skimmer around the plumbing? If so I think you may be alright. The concrete itself is very porous and will leak water visibly from the outside when it rains. Your actual waterproofing comes from your final plaster job.

If all they forgot was to fill the area behind/under the skimmer you can probably just fill that in after with concrete. It should really just be there for support. Did they fill all the area on the front side of the skimmer and bond beam that was reinforced with rebar? The rebar/concrete combination is really where you get your strength, not either working alone. Maybe post a couple pics.

Here are some pics of my skimmer rough-in before gunite. They filled these entire cavities under the skimmers, but I think it's really just to fill the void created when you dig out to install the rough plumb.

If all they forgot was to fill the area behind/under the skimmer you can probably just fill that in after with concrete. It should really just be there for support. Did they fill all the area on the front side of the skimmer and bond beam that was reinforced with rebar? The rebar/concrete combination is really where you get your strength, not either working alone. Maybe post a couple pics.

Here are some pics of my skimmer rough-in before gunite. They filled these entire cavities under the skimmers, but I think it's really just to fill the void created when you dig out to install the rough plumb.

It is the plaster that seals up the leaks. As long as the void isn't in the wall of the pool or the bond beam you will be fine. If it is in the bond beam or pool wall there may be a structural issue. Everything else just needs to be filled in properly before plastering. If the plaster is well supported and the skimmer is solidly set in place so it can't move, the plaster will seal everything up just fine and there won't be leaks.

Without a picture, it's hard to tell but I think cword is saying they did not do a continuous pour to encapsulate the skimmers and make the concrete around them a continuous part of the pool wall.

That may well result in a "cold" joint and allow some movement and shifting of the skimmers over time....a very, very bad thing.

If that's the case, and there is indeed a cold joint at the skimmers, I would consider that a HUGE problem.

Hopefully, they poured the buckets of concrete around the skimmers while the wall concrete was still setting and there is no joint at that point. If that's the case, there is no issue.

That may well result in a "cold" joint and allow some movement and shifting of the skimmers over time....a very, very bad thing.

If that's the case, and there is indeed a cold joint at the skimmers, I would consider that a HUGE problem.

Hopefully, they poured the buckets of concrete around the skimmers while the wall concrete was still setting and there is no joint at that point. If that's the case, there is no issue.

Cword, post some pics from all angles around th eskimmers for our gurus to decide. Your photos won't just speak tons but heavier than your whole pool.

pics of skimmer

here are some pics of the skimmer. If you need more tell me what angles would be most helpful and I'll go out and take some more. Thanks so much to all that will help.

here are some pics of the skimmer. If you need more tell me what angles would be most helpful and I'll go out and take some more. Thanks so much to all that will help.

Attachments

Well, if you haven't paid them, I wouldn't. That's pretty nasty work and they've left you with a cold joint to finish up.

I don't think it will cause you any long term grief but the fix is gonna take a little more skill than those guys apparently possess.

I would temporarily remove the forming behind the skimmer so I could work. That done, all that nasty, sloppy concrete work has to be chiseled out back to the bond beam. You need a fairly straight vertical surface on each side of the skimmer body because you are gonna want to insert rebar (3/8" is fine), 2 pieces on each side....4 total pieces.

You need to drill 4 - 3/8 holes horizontally about 3-4 inches into the bond beam.....spaced equally around the skimmer. Then drive the 3/8 rebar down into those four holes. Let the rebar extend from the holes backwards towards the back form and stop it about 2" short of the form.

Essentially, what this does is tie the two bodies of concrete together with the rebar. It's commonly called "pegging" and it locks the two pours together. If you simply fill new concrete into the void, it will not form the correct bond.

This is a labor intensive, not too easy task and may be a little overkill but if you do not do it, you always stand the possibility that the new pour will move seperately from the old one and your skimmer will crack. Then you'll need to tear up EVERYTHING and start over.

If you have financial leverage, of course you can get them to do it. Even then, I would make Dang sure they understood what you are trying to accomplish. Pegging can be done sloppily and it will do you no good.

Based on what I see of their work, sloppy seems to run in their nature.

I don't think it will cause you any long term grief but the fix is gonna take a little more skill than those guys apparently possess.

I would temporarily remove the forming behind the skimmer so I could work. That done, all that nasty, sloppy concrete work has to be chiseled out back to the bond beam. You need a fairly straight vertical surface on each side of the skimmer body because you are gonna want to insert rebar (3/8" is fine), 2 pieces on each side....4 total pieces.

You need to drill 4 - 3/8 holes horizontally about 3-4 inches into the bond beam.....spaced equally around the skimmer. Then drive the 3/8 rebar down into those four holes. Let the rebar extend from the holes backwards towards the back form and stop it about 2" short of the form.

Essentially, what this does is tie the two bodies of concrete together with the rebar. It's commonly called "pegging" and it locks the two pours together. If you simply fill new concrete into the void, it will not form the correct bond.

This is a labor intensive, not too easy task and may be a little overkill but if you do not do it, you always stand the possibility that the new pour will move seperately from the old one and your skimmer will crack. Then you'll need to tear up EVERYTHING and start over.

If you have financial leverage, of course you can get them to do it. Even then, I would make Dang sure they understood what you are trying to accomplish. Pegging can be done sloppily and it will do you no good.

Based on what I see of their work, sloppy seems to run in their nature.

I understand there is a type of epoxy (I do not know what you call it other there) which you partially fill the 4 3/8 holes you drill and insert the 4 bars.This will keep your 4 bars in place.

already paid

not only have I already paid, but the owner of the company that did the "work" had open heart surgery and I don't know when he will be back at work. Do you think I need a concrete person to do this work, or a pool builder? I don't really know who is the best person to call to get it fixed. Any other opinions or suggestions here? Thank you again for your help.

not only have I already paid, but the owner of the company that did the "work" had open heart surgery and I don't know when he will be back at work. Do you think I need a concrete person to do this work, or a pool builder? I don't really know who is the best person to call to get it fixed. Any other opinions or suggestions here? Thank you again for your help.

I think the integrity of your poolwall looks fine. You just need to make sure the skimmer is properly supported and protected and joined to the outside of the bondbeam so it won't sag down with the weight of your pool deck.

Like duraleigh said, chip away the chunky loose gunite from the box. Dig out the soft mud and get down to firm hard ground. You should probably "peg" or "dowel" the bond beam (you will need a rock drill and concrete bit) with some 3/8" rebar and bend it around the backside of the skimmer (like the 3rd picture up above), and then pour some new concrete in to fill the hole up to about 3 inches below the skimmer top and sloping down. Make sure you DO NOT encase your plumbing lines that go into the bottom of the skimmer. Find them and extend them if you have to.

This is the only picture I have of the back of my skimmers after the gunite was shot. On the right side, you can see the gunite around the skimmer. Nevermind the mess...

As far as who to get? Well part of being an owner builder...you get to pick up the slack and miscellaneous parts of the build. You can rent a concrete drill and buy some rebar at Home Depot/Lowes. There's probably some laying around your yard still from the tie job. Practice on some old concrete somewhere if you have some in your yard...an old outbuilding or well pump house slab maybe? It's not too tough. Just wrap some electrical tape around the bit as a depth set so you don't drill too deep. I'd say about 4" into the bond beam, NOT the pool wall. Try to stay several inches away from any edges. After the holes are drilled, pound the rebar in with a 5# hammer and bend them into shape. Mix and pour concrete and roughly shape it.

You could probably explain this process to any concrete foundation guy to do also. They'll have the tools and be familiar with working concrete, just not pool construction. They'll cost you a few bucks though. Otherwise, I'd say just be patient and wait for the original PB and make HIM come out and fix it properly. That would probably be the best anyways, then he can't blame you for any problems later on.

Remember the point is to support and protect the skimmer, not pull it down and away from the pool wall. If you just pour a big pile of concrete around it withough tieing it in, it'll do more damage than good.

Like duraleigh said, chip away the chunky loose gunite from the box. Dig out the soft mud and get down to firm hard ground. You should probably "peg" or "dowel" the bond beam (you will need a rock drill and concrete bit) with some 3/8" rebar and bend it around the backside of the skimmer (like the 3rd picture up above), and then pour some new concrete in to fill the hole up to about 3 inches below the skimmer top and sloping down. Make sure you DO NOT encase your plumbing lines that go into the bottom of the skimmer. Find them and extend them if you have to.

This is the only picture I have of the back of my skimmers after the gunite was shot. On the right side, you can see the gunite around the skimmer. Nevermind the mess...

As far as who to get? Well part of being an owner builder...you get to pick up the slack and miscellaneous parts of the build. You can rent a concrete drill and buy some rebar at Home Depot/Lowes. There's probably some laying around your yard still from the tie job. Practice on some old concrete somewhere if you have some in your yard...an old outbuilding or well pump house slab maybe? It's not too tough. Just wrap some electrical tape around the bit as a depth set so you don't drill too deep. I'd say about 4" into the bond beam, NOT the pool wall. Try to stay several inches away from any edges. After the holes are drilled, pound the rebar in with a 5# hammer and bend them into shape. Mix and pour concrete and roughly shape it.

You could probably explain this process to any concrete foundation guy to do also. They'll have the tools and be familiar with working concrete, just not pool construction. They'll cost you a few bucks though. Otherwise, I'd say just be patient and wait for the original PB and make HIM come out and fix it properly. That would probably be the best anyways, then he can't blame you for any problems later on.

Remember the point is to support and protect the skimmer, not pull it down and away from the pool wall. If you just pour a big pile of concrete around it withough tieing it in, it'll do more damage than good.

Thank you very much for the suggestions. I am going to take some additional pics of the skimmers. The gunite guys poured 2 buckets of gunite into the bottom of the skimmer box. You cannot see it in the above pic as it rained afterward and mud is covering the bottom. Would this gunite in the bottom of the skimmer box need to be busted out as well? My husband does not min doing the actual work on this himself he is just scared he may actually mess it up even more so not knowing how to drill into gunite. Do either of you know of a website that might show a diagram of where to drill the holes, put the rebar, etc? Or if someone would be willing to draw it out by hand and email or fax it to me I would be happy to pay for their time.

Link to more pics.

I have included a link to photo bucket with several more pics so as not to junk up this site with so many pics. I removed the form and the mud that was on top of the concrete. The gunite guy poured 2 buckets of gunite down into the formed up box so what you are seeing in the bottom is concrete (with dried dirt stuck to it) Does all that gunite in the bottom need to be busted out? That will not be an easy job for sure. Hopefully this pics will give you a better look since I removed the form, and took several more angles. Any change in opinion after viewing these or pretty much still a cold joint mess? Thanks again to all who help

http://s282.photobucket.com/albums/kk261/cwuer/

I have included a link to photo bucket with several more pics so as not to junk up this site with so many pics. I removed the form and the mud that was on top of the concrete. The gunite guy poured 2 buckets of gunite down into the formed up box so what you are seeing in the bottom is concrete (with dried dirt stuck to it) Does all that gunite in the bottom need to be busted out? That will not be an easy job for sure. Hopefully this pics will give you a better look since I removed the form, and took several more angles. Any change in opinion after viewing these or pretty much still a cold joint mess? Thanks again to all who help

http://s282.photobucket.com/albums/kk261/cwuer/

I still think the same thing. Pain in the a** but not a disaster. Either wait for the original gunite contractor to come back and finish it correctly, or get a little dirty.

I doubt there would be any actual official drawings of something like this. Just remember what you're objective is, support and protect the skimmer, not drag it down and away from the bond beam.

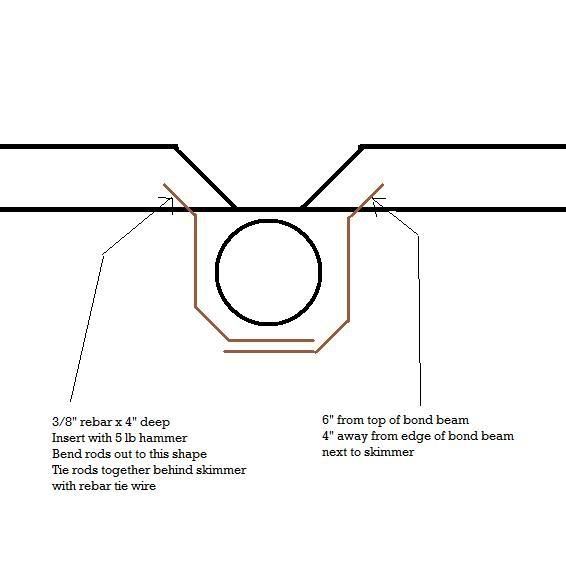

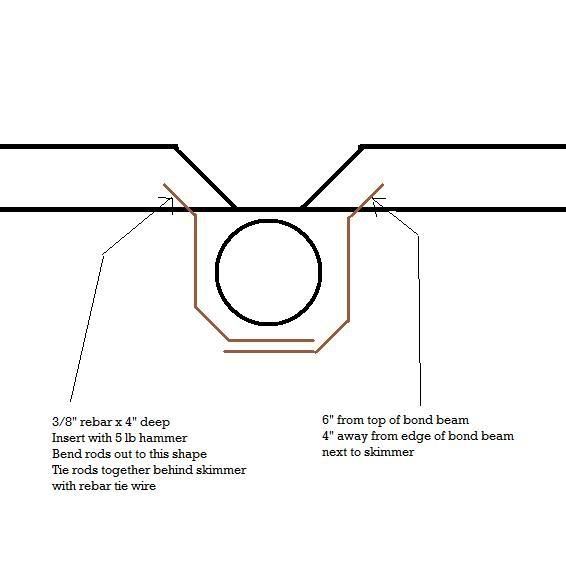

Whenever you dowel concrete, it's good to stay 4"+ away from any edges if possible. So, if it were me, I would center up on your 12" bond beam (6" from top and drill in 4" deep at an angle at least 4" from where the smooth of the back of your bond beam starts). Insert rods with hammer and bend the rebar alongside and then around back of the skimmer and tie together with rebar tie wire. Dig out any loose mud down to good solid ground and form up a small area with some boards. Keep the level at least three inches below skimmer top so your patio decking can fill in above and still have the strength it needs. Absolutely do not bury access to your plumbing lines if they've not been hooked up and pressure tested yet. Make sure the back of your bond beam is clean before pouring the new concrete in the forms. If you wet it first, it will help the new concrete adhere a little better. I would break off any of the big loose chunks, but leave it rough and that will also help adhesion.

When you rent the hammer drill, make sure you specify this is for concrete, not masonry. They will probably even supply you with a 3/8" bit.

Here is a (very) rough sketch of what I would do.

OK, here's my disclaimer...I am NOT a professional pool builder by any stretch. Nor am I a mechanical or structural engineer. I've just worked around construction of various types for most of my life. If anyone else here has a different take on this, feel free to chime in.

In either case, I hope this all works out well. Your build is progressing nicely. You'll probaby beat me to the finish line!

I doubt there would be any actual official drawings of something like this. Just remember what you're objective is, support and protect the skimmer, not drag it down and away from the bond beam.

Whenever you dowel concrete, it's good to stay 4"+ away from any edges if possible. So, if it were me, I would center up on your 12" bond beam (6" from top and drill in 4" deep at an angle at least 4" from where the smooth of the back of your bond beam starts). Insert rods with hammer and bend the rebar alongside and then around back of the skimmer and tie together with rebar tie wire. Dig out any loose mud down to good solid ground and form up a small area with some boards. Keep the level at least three inches below skimmer top so your patio decking can fill in above and still have the strength it needs. Absolutely do not bury access to your plumbing lines if they've not been hooked up and pressure tested yet. Make sure the back of your bond beam is clean before pouring the new concrete in the forms. If you wet it first, it will help the new concrete adhere a little better. I would break off any of the big loose chunks, but leave it rough and that will also help adhesion.

When you rent the hammer drill, make sure you specify this is for concrete, not masonry. They will probably even supply you with a 3/8" bit.

Here is a (very) rough sketch of what I would do.

OK, here's my disclaimer...I am NOT a professional pool builder by any stretch. Nor am I a mechanical or structural engineer. I've just worked around construction of various types for most of my life. If anyone else here has a different take on this, feel free to chime in.

In either case, I hope this all works out well. Your build is progressing nicely. You'll probaby beat me to the finish line!

Bill Jones will not stand behind his work

Well... I finally talked to the owner of the company that shot my gunite shell (He is out of Hattiesburg, Mississippi) He was adamant in saying there was no need to do any pegging, etc and all I needed to do was to fill up that hole with concrete when the decking was poured. He said there was rebar behind the skimmer and under the 2 buckets of gunite the workers poured down in the hole. I told him there was not any rebar behind the skimmer under those 2 buckets of gunite and he said "Well that is not my problem; that is the person that did your steel because there should have been steel behind that skimmer." He was adamant, loud, insistent, and finally I just said "Well I am not comfortable doing what you are advising." and I let it go because it was obvious he was not going to do anything to help resolve the problem. Is he right though in saying the guy that did my steel did not do it properly, or is there more than one way to do this? Now I am worried because I'm sure the other skimmer was done the same as this one as far as the steel goes. The other skimmer frame was filled with gunite at the shoot though it was just this one that was missed. Do I need to be concerned now that the other skimmer was not done correctly? I am going to work on fixing this one this week. I am going to follow the instructions I have been given on this forum. One thing I am still uncertain about. Do I need to somehow remove the gunite in the bottom of the hole (the 2 buckets of gunite they poured into the box) or can I do the stated repairs and pour new concrete on top of that. If I have to bust out all that gunite in the bottom of the box that will be very difficult.

Well... I finally talked to the owner of the company that shot my gunite shell (He is out of Hattiesburg, Mississippi) He was adamant in saying there was no need to do any pegging, etc and all I needed to do was to fill up that hole with concrete when the decking was poured. He said there was rebar behind the skimmer and under the 2 buckets of gunite the workers poured down in the hole. I told him there was not any rebar behind the skimmer under those 2 buckets of gunite and he said "Well that is not my problem; that is the person that did your steel because there should have been steel behind that skimmer." He was adamant, loud, insistent, and finally I just said "Well I am not comfortable doing what you are advising." and I let it go because it was obvious he was not going to do anything to help resolve the problem. Is he right though in saying the guy that did my steel did not do it properly, or is there more than one way to do this? Now I am worried because I'm sure the other skimmer was done the same as this one as far as the steel goes. The other skimmer frame was filled with gunite at the shoot though it was just this one that was missed. Do I need to be concerned now that the other skimmer was not done correctly? I am going to work on fixing this one this week. I am going to follow the instructions I have been given on this forum. One thing I am still uncertain about. Do I need to somehow remove the gunite in the bottom of the hole (the 2 buckets of gunite they poured into the box) or can I do the stated repairs and pour new concrete on top of that. If I have to bust out all that gunite in the bottom of the box that will be very difficult.

Picture of repair

I got the guy that has been doing most of the work on my pool to do the pegging to the skimmer area yesterday. I told him how it was recommended here that it be done. However..... he insisted that using one bar of rebar bent around was better than two on each side bent back and tied. He filled the hole with liquid epoxy. it was called Liquid roc 5000. He also ran 2 bars of rebar into the concrete in the bottom to peg it (as recommend here) He said to let this set for 24 hours, then frame it up and pour concrete into it just above the top rebar (about 3 1/2-4 inchese from top of coping) Does this look like an appropriate fix to you guys that have been following this and helping me out? Is is OK to get concrete from Lowes to fill it in. he recommend mixing 2 bags quick crete to 1 bag portland. Any thoughts. I hope to get this finished today so I can stop worrying about it. Thanks again.

here is the link

http://s282.photobucket.com/albums/kk26 ... 0_6440.jpg

http://s282.photobucket.com/albums/kk26 ... 0_6443.jpg

I got the guy that has been doing most of the work on my pool to do the pegging to the skimmer area yesterday. I told him how it was recommended here that it be done. However..... he insisted that using one bar of rebar bent around was better than two on each side bent back and tied. He filled the hole with liquid epoxy. it was called Liquid roc 5000. He also ran 2 bars of rebar into the concrete in the bottom to peg it (as recommend here) He said to let this set for 24 hours, then frame it up and pour concrete into it just above the top rebar (about 3 1/2-4 inchese from top of coping) Does this look like an appropriate fix to you guys that have been following this and helping me out? Is is OK to get concrete from Lowes to fill it in. he recommend mixing 2 bags quick crete to 1 bag portland. Any thoughts. I hope to get this finished today so I can stop worrying about it. Thanks again.

here is the link

http://s282.photobucket.com/albums/kk26 ... 0_6440.jpg

http://s282.photobucket.com/albums/kk26 ... 0_6443.jpg

I personally wouldn't bust any concrete out from around the other skimmer. It's pretty tough stuff and you'd risk doing more damage than good.

I think the repair looks good, I'd just form up around it like he said and go with it.

I think the repair looks good, I'd just form up around it like he said and go with it.

I think that belldivers method would have been better for one reason. His diagram shows the rebar pegs drilled at an angle. This helps prevent the new concrete from pulling straight away from the exising gunite. If the rebar is drilled straight you are relying on the strength of the epoxy. Who knows...adhesives these days are pretty strong.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.